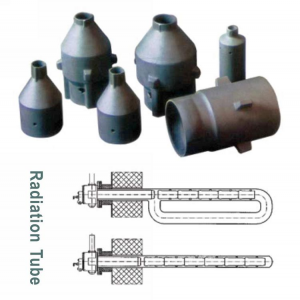

Silicon carbide radiant tube

Cov khoom siv silicon carbideyog cov khoom siv hluav taws xob zoo tshaj plaws ntawm qhov cub, qhov cub hluav taws xob, cov menyuam ntawm lub tshuab hluav taws xob li cov nplaim hluav taws xob.

Nrog rau qhov kub thiab txias thermal conductivity, zoo, ceev txias hauv tshav kub tsis kam, tsis kam oxidation, thermal shock kuj zoo, lub neej ntev.

Nta:

• Kev txuag hluav taws xob zoo heev.

• Lub cev nyhav dua thiab muaj peev xwm thauj khoom ntau dua.

• Zoo heev distortion kuj ntawm qhov kub thiab txias.

• Siab thermal conductivity

• High Young's modulus

• Tsawg thermal expansion coefficient

• Siab hardness heev

• Hnav tiv taus

Daim ntawv thov:

• Cov khoom siv tu cev

• Kiln rooj tog crucibles

• iav vaj huam sib luag kev lag luam

• zawv zawg bearings

• ci ntsa iab ntawm cov rooj zaum.

• Kub exchangers

• Burners

• Hnav cov khoom (cov lus qhia)

RBSiC (SiSiC) nozzles yog siv rau qhov kub thiab txias systems ntawm qhov cub, shuttle kilns thiab ntau yam

lwm cov chaw tsim khoom lag luam. RBSiC(SiSiC) hla kab muaj zog dua thiab tsis muaj deformations txawm tias kub heev.

Specification

| Properites | Chav tsev | Silicon carbide khoom | ||||||

| Hom | SiC | SiSiC | NSiC | RSiC | ||||

| Tshuaj muaj pes tsawg leeg | SiC% | 89 | 87 | 92 | 70 | 99 | ||

| SiO 2% | 5 | 6 | - | Txa3N4 28 | - | |||

| Al2O3% | 1.0 | 2.0 | - | - | - | |||

| Bulk Desity | g/cm3 | 2.85 ib | 2.8 | 3.01 Nws | 2.8 | 2.75 ib | ||

| Pom tseeb porosity | % | 12 | 14 | 0.1 | 12 | 14 | ||

| MOR @ 20 ℃ | MPa | 50 | 48 | 260 | 180 | 100 | ||

| MOR @ 1300 ℃ | MPa | 58 | 56 | 280 | 185 | 120 | ||

| CTE @ 20 ℃ -1000 ℃ | 10-6K-1 | 4.8 | 4.2 | 4.5 | 4.7 | 4.6 | ||

| CCS | MPa | 100 | 90 | 900 | 500 | 300 | ||

| Thermal shock tsis kam | ★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ||

RBSiC (SiSiC) nozzles / beams / rollers yog siv rau kev thauj khoom cov qauv ntawm qhov chaw kilns, shuttle kilns thiab ntau yam

lwm cov chaw tsim khoom lag luam. RBSiC(SiSiC) hla kab muaj zog dua thiab tsis muaj deformations txawm tias kub heev.

Thiab tseem cov kab teeb pom kev ua haujlwm ntev ntev.Cov kab teeb yog cov rooj tog zaum zoo tshaj plaws rau cov khoom siv tu cev thiab cov khoom siv hluav taws xob porcelain. RBSiC (SiSiC) muaj cov thermal conductivity zoo heev, yog li nws muaj peev xwm txuag hluav taws xob nrog qhov hnyav ntawm lub tsheb kiln.

Ntim & Shipping

1.50 daim nyob rau hauv ib lub thawv ntoo (tag nrho enclosed, nyab xeeb thiab ruaj ntseg)

2.800kg ~ 1000kg / thawv ntoo.

3.Kev tiv thaiv kev sib tsoo xws li ua npuas ncauj

4.3-txheej ntoo vaj huam sib luag, ruaj khov, cuam tshuam resistant, poob resistant

Cov ntsiab lus shipping

1.Professional tsheb thauj mus rau ntau qhov chaw nres nkoj hauv Suav teb, tom qab ntawd thauj khoom los ntawm lub tuam txhab kev thauj khoom.

2.FOB thiab CIF tuaj yeem ua haujlwm yooj yim.

3. Kev sib tw hiav txwv freight thiab caij luv luv.

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qho ntawm cov loj tshaj plaws silicon carbide ceramic cov khoom siv tshiab hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais tau nrawm, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.