Silicon Carbide Tag Nrho Lub Taub Hau Spial Nozzle

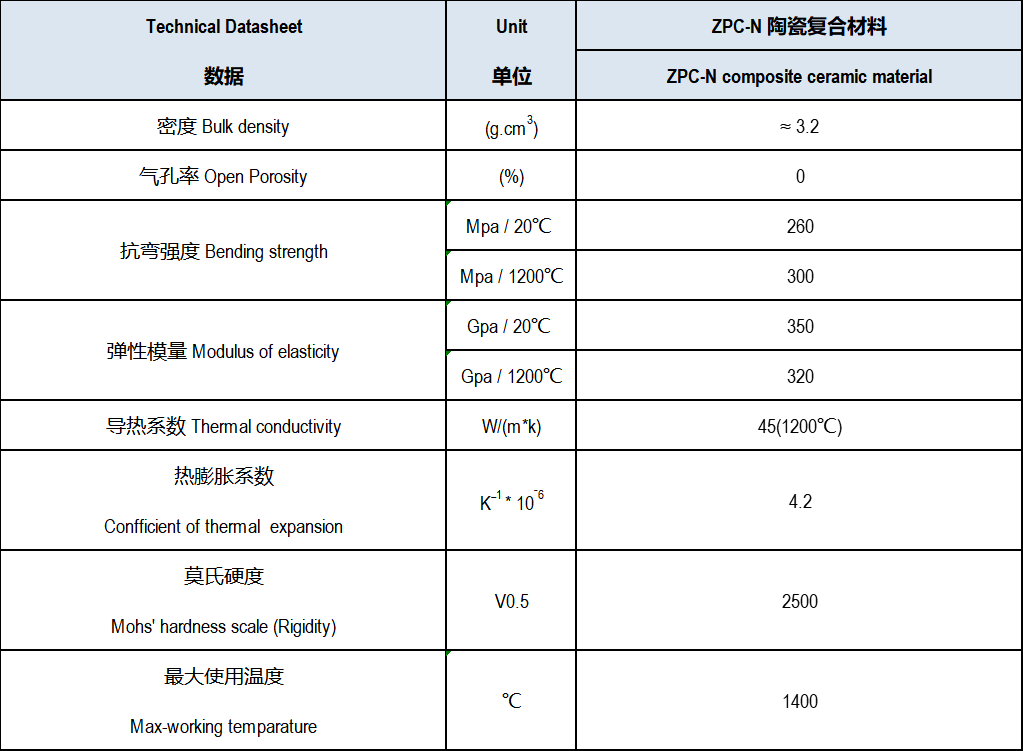

Technical Datasheet:

Ua hauj lwm hauv paus ntsiab lus ntawm silicon carbide kauv nozzle

Thaum cov kua uas muaj qee qhov siab thiab ceev ntws los ntawm sab saum toj mus rau RBSC / SiSiC kauv nozzle, cov kua nyob rau sab nrauv tsoo lub helicoid nrog ib lub kaum sab xis ntawm lub nozzle. Qhov no tuaj yeem hloov cov tshuaj tsuag kom deb ntawm lub nozzle. Lub kaum sab xis suav nrog (helix lub kaum sab xis) nruab nrab ntawm qhov streamline ntawm qhov chaw ntawm lub khob hliav qab ntawm cov txheej txheem sib txawv thiab qhov nruab nrab ntawm lub nozzle yog maj mam txo.Nws yog conductive kom npog thaj tsam ntawm cov kua ejected zoo.

RBSC/SiSiC kauv nozzle yog ib qho kev siv rau desulphurization thiab dedust. Nws tuaj yeem tsim lub khob hliav qab thiab cov khoom siv lub khob hliav qab nrog lub kaum sab xis ntawm 60 txog 170 degrees. Los ntawm kev txiav thiab sib tsoo nrog lub cev me me txuas ntxiv mus, cov kua yuav tig mus rau hauv cov kua me me rau hauv cov kab noj hniav ntawm lub nozzle. Tus tsim ntawm txoj kev los ntawm kev ntshuam mus rau qhov kev tawm yog tsis muaj kev cuam tshuam los ntawm cov hniav thiab cov lus qhia. Nyob rau hauv cov ntaub ntawv ntawm tib lub ndlwg, qhov siab tshaj plaws unblocked txoj kab uas hla ntawm lub kauv nozzle yog ntau tshaj 2 npaug ntawm cov pa nozzle. Qhov no tuaj yeem txo qhov tshwm sim ntawm kev cuam tshuam mus rau qhov loj tshaj plaws.

Silicon Carbide yog lub teeb, tsis tshua muaj zog, thiab corrosion resistant cov ntaub ntawv uas ua rau nws muaj zog neeg sib tw rau hnav daim ntaub ntawv nyob rau hauv lub harshest ib puag ncig. Silicon Carbide kuj muaj lwm yam khoom siv xws li thermal conductivity zoo heev thiab cov tub ntxhais hluas modulus siab.

- Daim ntawv thov

- Semiconductor txheej txheem khoom Parts

- General industrial machinery qhov chaw

- Abrasion Resistance ib feem

Lub tshuab nqus tsev cov tshuaj tiv thaiv sintered silicon carbide desulphurization nozzle yog qhov tseem ceeb ntawm kev ua tiav ntawm desulphurization thiab cov khoom tshem tawm plua plav rau thermal fais fab nroj tsuag, boiler loj. Cov khoom muaj cov khoom zoo xws li lub zog siab, siab hardness, muaj zog corrosion kuj, hnyav hnyav thiab kub tsis kam. Cov tshuaj tiv thaiv sintered silicon carbide desulfurization atomizer ua los ntawm peb lub tuam txhab muaj kev faib tawm ntawm cov tee dej, tsis muaj kev cuam tshuam cov dej ntws, thiab hloov pauv cov khoom lag luam tag nrho, sau cov khoom hauv tsev. Tam sim no, muaj peb series ntawm vortices, spirals thiab kua kab, uas tau siv nyob rau hauv desulphurization thiab plua plav tshem tawm cov cuab yeej ntawm ntau thermal fais fab nroj tsuag thiab boilers loj, thiab nyob rau hauv kev ua haujlwm zoo.

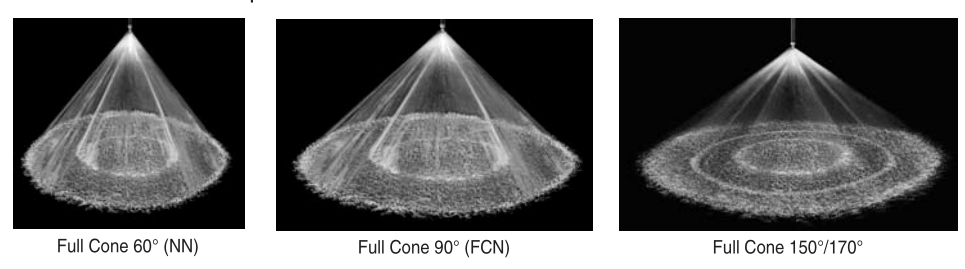

Txau cov nyhuv ntawm cov khoom cone kauv nozzles

Puv Cone Flow Rates thiab Dimensions

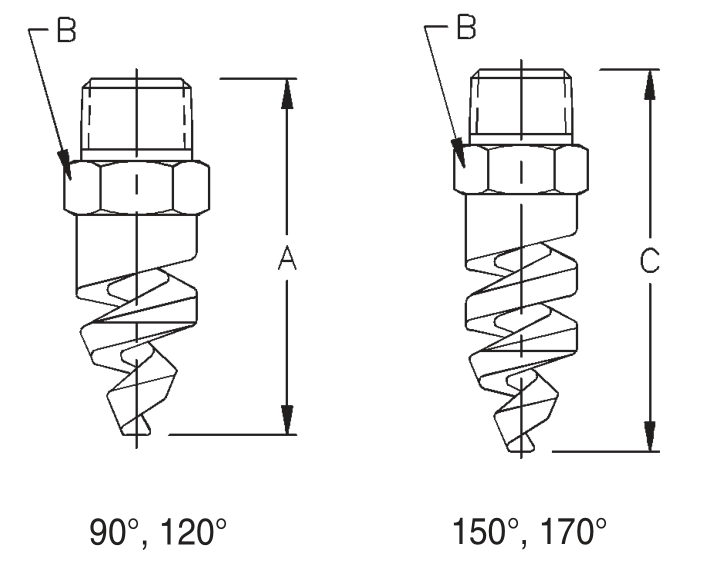

Lub khob hliav qab, 60 ° (NN), 90 ° (FCN lossis FFCN), 120 ° (FC lossis FFC), 150 °, thiab 170 ° Txau lub kaum sab xis, 1/8 "rau 4" Yeeb Nkab Loj

Spray Angles:

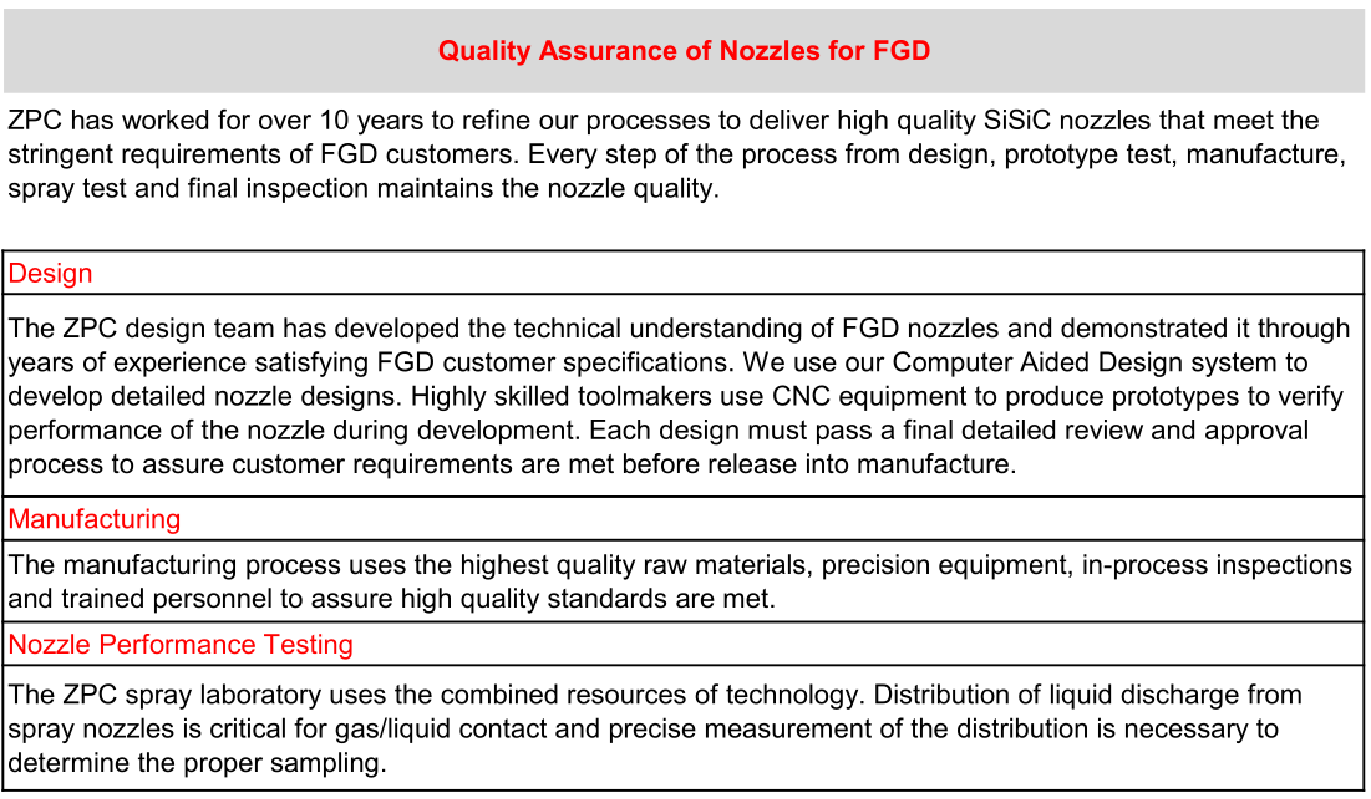

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qho ntawm cov loj tshaj plaws silicon carbide ceramic cov khoom siv tshiab hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais tau nrawm, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.