Mugadziri (fekitari) yeSilicon Cabide zvidhinha, mahwendefa, mataira

Iyo Silicon Carbide inoshivirira huwandu hwakawanda hweasidhi uye alkalis. Uye nekuita kwakanakisa kwesimba repamusoro, kuomarara kwepamusoro, kupfeka kwakanyanya kuramba, kupisa kwekushisa kwakanyanya, corrosion resistance. Mhando dzakasiyana dzemaumbirwo ezvikamu zvakakosha dzakakodzera kumigodhi, petrochemical, metallurgical kugadzira, aerospace uye maindasitiri enyukireya, senge nharaunda yakatarwa. Tinogona kuita chero hukuru hwakapihwa maererano nechikumbiro chemutengi.

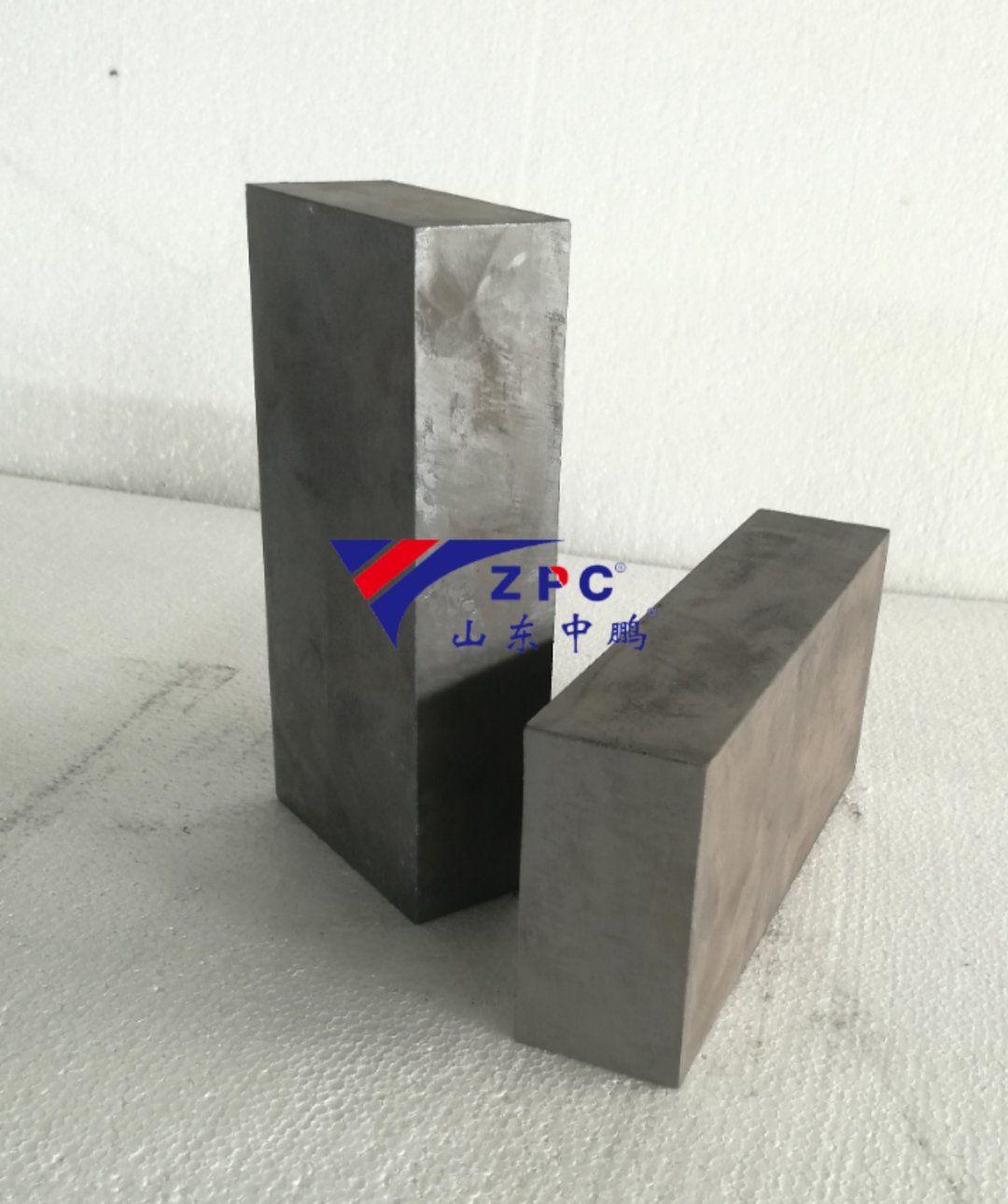

Kupfeka kuramba, kusimba kwekushisa kwepamusoro uye kushorwa kunoita kuti Reaction Bonded SiC ive yakanakira zvinhu zvekupfeka, senge pombi liner, zvidhinha, mataira, zvidhinha, nezvimwe.

| Vatambi venyama | Unit | Properties |

| SIC zvemukati | % | 95-88 |

| Free Si | % | 5~12 |

| Bulk density | g/cm3 | >3.02 |

| Porosity | % | <0.1 |

| Kuoma | Kg/mm2 | 2400 |

| Coefficient yekukotama simba pa20 degrees Celsius | Mpa | 260 |

| Coefficient yekubhenda simba pa1200 degrees Celsius | Mpa | 280 |

| Modulus ye elasticity pa20 Degrees Celsius | Gpa | 330 |

| Kutsemuka kuomarara | Mpa*m1/2 | 3.3 |

| Coefficient of thermal conductivity pa 1200 degrees Celsius | W/mk | 45 |

| Coefficient yekuwedzera kwekupisa pa1200 degrees Celsius | 10-6mm/mmK | 4.5 |

| Coefficient of heat radiation | <0.9 | |

| Max. Kushanda tembiricha | ºC | <1380 |

Silicon Carbide SiC (SiSiC/RBSiC) Zvimiro:

Abrasion / Corrosion resistance

Yakanakisa thermal shock maitiro

Yakanakisa oxidation kuramba

Yakanaka dimensional kutonga kwezvimiro zvakaoma

High thermal conductivity

Kuvandudzwa kwekuita

Hupenyu hurefu pakati pekutsiva / kuvakazve

Kupokana nekuora

Superior Resistance kupfeka

Simba pakupisa kwepamusoro kusvika 1380°C

Silicon carbide plates application:

SiC silicon carbide plate uye mataira imhando yeyakakosha ceramic plate inoshandiswa zvakanyanya mune akawanda maindasitiri zvigadzirwa:

Indasitiri yeMigodhi, Indasitiri yemuchina, Indasitiri yeKemikari, Crystallite Girazi Indasitiri, Magnetic Materials Indasitiri, Metallurgy, Metallurgy Indasitiri, Pepa Indasitiri, Petroleum Indasitiri, kiln, nezvimwewo.

Yakagadzirirwa silicon carbide zvigadzirwa, chimiro chiripo: mahwendefa, zvidhinha, mataira, radian ndiro, screw, plain plate, straight pombi, tee pombi, mhete, gokora, cone dutu uye zvichingodaro.

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yeyakakura silicon carbide ceramic zvinhu zvitsva zvinogadziriswa muChina. SiC technical ceramic: Kuomarara kweMoh ndeye 9 (Kuoma kweMoh kutsva ndeye 13), nekupokana kwakanyanya kukukurwa nekuora, kunyura kwakanakisa - kuramba uye anti-oxidation. Hupenyu hwesevhisi yechigadzirwa cheSiC hwakareba 4 kusvika kashanu kupfuura 92% alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Iyo quotation process inokurumidza, kuendesa kwakavimbiswa uye mhando ndeyechipiri kune imwe. Isu tinogara tichishingirira kupikisa zvinangwa zvedu uye nekudzorera moyo yedu kunharaunda.