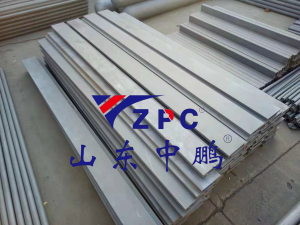

Silicon carbide kiln burner nozzles mugadziri

Silicon carbide burner nozzles imhando yechigadzirwa chine simba rakawanda, kuomarara kwepamusoro, kupfeka kwakanyanya kuramba, uye yakanaka oxidation kuramba, kupisa kwekuvhunduka uye zvimwe zvinhu. RBSIC ine yakanyanya kunaka kuita kwenguva refu (Kuenzaniswa neRESIC neSNBSC) simba rekukotama rinopfuura kaviri pane RESIC, 50% yakakwirira kupfuura SNBSC.

Reaction yakasungirirwa silicon carbide ceramic application:

Iwo akasiyana maviramu emaindasitiri, midziyo yedesulphurization, mabhoiers makuru nemimwe michina, uye ceramics, muchina, simbi, zvemagetsi, makemikari, petroteum, simbi nesimbi indasitiri, indasitiri yemauto, indasitiri yendege nezvimwe minda.

Technical database:

| Density | g/cm3 | 3.02 |

| Inooneka porosity | % | <0.1 |

| Bending Strength | Mpa | 250(20℃) |

| Mpa | 280(1200℃) | |

| Modulus yeElasticity | Gpa | 330(20℃) |

| Gpa | 300(1200℃) | |

| Thermal Conductivity | W/mk | 45(1200℃) |

| Thermal Tsanangudzo | k-1×10-6 | 4.5 |

| Vickers-kuoma | Gpa | 20 |

| Acid-Proof Alikaline | Excellent |

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yeyakakura silicon carbide ceramic zvinhu zvitsva zvinogadziriswa muChina. SiC technical ceramic: Kuomarara kweMoh ndeye 9 (Kuoma kweMoh kutsva ndeye 13), nekupokana kwakanyanya kukukurwa nekuora, kunyura kwakanakisa - kuramba uye anti-oxidation. Hupenyu hwesevhisi yechigadzirwa cheSiC hwakareba 4 kusvika kashanu kupfuura 92% alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Iyo quotation process inokurumidza, kuendesa kwakavimbiswa uye mhando ndeyechipiri kune imwe. Isu tinogara tichishingirira kupikisa zvinangwa zvedu uye nekudzorera moyo yedu kunharaunda.