Tshwj xeeb Shape Silicon Carbide Cov Khoom Tshiab Ceramic

Reaction-bonded silicon carbide (si-sic) sic ceramic, raug tsim xoom porosity los ntawm kev sau qhib porosity nrog silicon hlau (si). Vim tias nws yog xoom porosity yam ntxwv, thermal conductivity yog ntau tshaj ob zaug ntawm oxide bonded sic's, khoov lub zog yog ntau tshaj 5 npaug siab dua piv rau oxide bonded sic.

Sic qhov tshwj xeeb yog nws lub peev xwm los tuav lub zog siab ntawm chav tsev kub txog 1,380 ° C. Tsis tas li ntawd nws muaj oxidation siab heev, tshuaj tiv thaiv thiab hnav tsis kam. Siv ua beam, roller, radiant tube burner thiab burner nozzle thiab lwm yam.

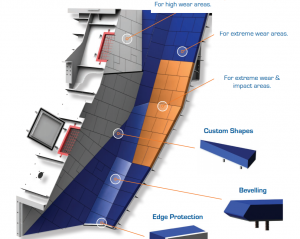

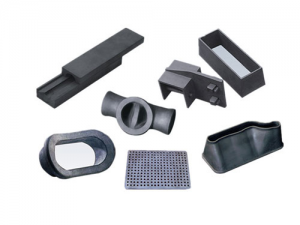

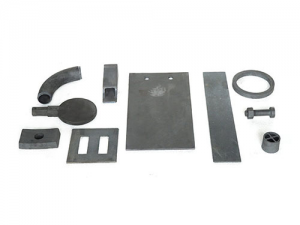

Cov tshuaj tiv thaiv Bonded Silicon Carbide zam ntau yam acids thiab alkalis. Thiab nrog kev ua tau zoo ntawm lub zog siab, siab hardness, siab hnav tsis kam, kub tsis kam, corrosion kuj. Qhov sib txawv ntawm cov duab ntawm qhov tshwj xeeb yog tsim rau mining, petrochemical, metallurgical manufacturing, aerospace thiab nuclear industries, xws li ib puag ncig tshwj xeeb. Peb tuaj yeem ua txhua qhov ntau thiab tsawg raws li cov neeg siv khoom thov.

Hnav tsis kam, kub siab zog thiab corrosion kuj ua Reaction Bonded SiC yog ib qho khoom siv zoo tagnrho rau cov khoom hnav, xws li cov ntsia hlau, phaj thiab impellers. Nws kuj tseem tuaj yeem siv rau hauv cov kabmob thrust uas tuaj yeem nqa cov khoom hnyav heev hauv cov kua dej ntau.

Silicon Carbide SiC (SiSiC / RBSiC) Nta:

Abrasion / Corrosion kuj

Cov yam ntxwv zoo thermal shock

Zoo heev oxidation tsis kam

Kev tswj qhov zoo ntawm cov duab zoo

High thermal conductivity

Kev ua tau zoo dua

Lub neej ntev ntawm kev hloov / rov tsim dua

Kev tiv thaiv corrosion

Superior Resistance rau hnav

Lub zog ntawm qhov kub thiab txias txog li 1380 ° C

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qho ntawm cov loj tshaj plaws silicon carbide ceramic cov khoom siv tshiab hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais tau nrawm, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.