SiC Crucibles thiab Saggers Chaw tsim tshuaj paus / Hoobkas - SiC Sagger rau Powder Sintering

SiC Sagger rau Powder Sintering

RBSIC / SISIC crucible yog lub tais tob ntawm cov thawv ceramic. Vim tias nws qhov kev ua tau zoo dua li iav iav ntawm cov khoom siv hluav taws xob, Nws yog siv tau zoo thaum cov khib nyiab raug cua sov los ntawm hluav taws.

Sagger yog ua los ntawm refractory av nkos ntawm ntau yam specifications ntawm lub mortar, ci nyob rau hauv high kub. Nws yog ib qho tseem ceeb ntawm cov rooj tog zaum hauv qhov cub rau hlawv cov plooj (porcelain). Txhua hom porcelain yuav tsum muab tso rau hauv saggers ua ntej thiab tom qab ntawd mus rau hauv qhov cub rau ci.

SPECIFICATION:

| Index | RSiC | NSiC | RBSiC | SiC |

| Qhov ceev (g / cm3) | 2.65-2.75 Nws | 2.75-2.85 Nws | ≥3.02 | 2.8 |

| SiC(%) | ≥99 | ≥75 | 83.66 ib | 90 |

| Si3N4 (%) | 0 | ≥ 23 | 0 | 0 |

| Si(%) | 0 | 0 | 15.65 Nws | 9 |

| Porosity (%) | 15-18 | 10-12 | 0.1 | 7–8 |

| Bending zog (MPa) | 80-100 (20 ℃) | 160-180 (20 ℃) | 250 (20 ℃) | 500 (20 ℃) |

| Bending zog (MPa) | 90-110 (1200 ℃) | 170-180 (1200 ℃) | 280 (1200 ℃) | 550 (1200 ℃) |

| Bending zog (MPa) | 90-120 (1350 ℃) | 170-190 (1350 ℃) | - | - |

| Modulus ntawm elasticity (GPa) | 300 (20 ℃) | 580 (20 ℃) | 330 (20 ℃) | 200 |

| Modulus ntawm elasticity (GPa) | - | - | 300 (1200 ℃) | - |

| Thermal conductivity (wm-1.k-1) | 36.6 (1200 ℃) | 19.6 (1200 ℃) | 45 (1200 ℃) | 13.5-14.5 (1000 ℃) |

| Coefficient ntawm thermal expansion (K-1 × 10-6) | 4.69 ib | 4.7 | 4.5 | 3 |

| Rigidity | - | - | 13 | - |

| Max ua haujlwm kub (℃) | 1620 (Oxid) | 1450 | 1380 | 1300 |

Factory:

Hais txog peb:

Peb yog ib lub tuam txhab tshwj xeeb hauv kev tsim cov RBSIC / SISIC Silicon Infiltrated Silicon Carbide Khoom.

- Cov txheej txheem ntau lawm

- Imported High Quality Raw Materials

- Ua tiav Kev Tswj Xyuas Ntau Lawm

CATALOGUE:

Qhov zoo:

- Siab zog thiab hardness heev

- Kub kub tsis kam thiab zoo heev thermal shock kuj

- Cov kabmob muaj peev xwm zoo heev

- Resistance rau huab cua kub thiab txias.

- High kub creep kuj

- Corrosion kuj thiab Oxidation kuj

- Acid thiab alkali tsis kam

- Hnav tsis kam & zoo thermal conductivity

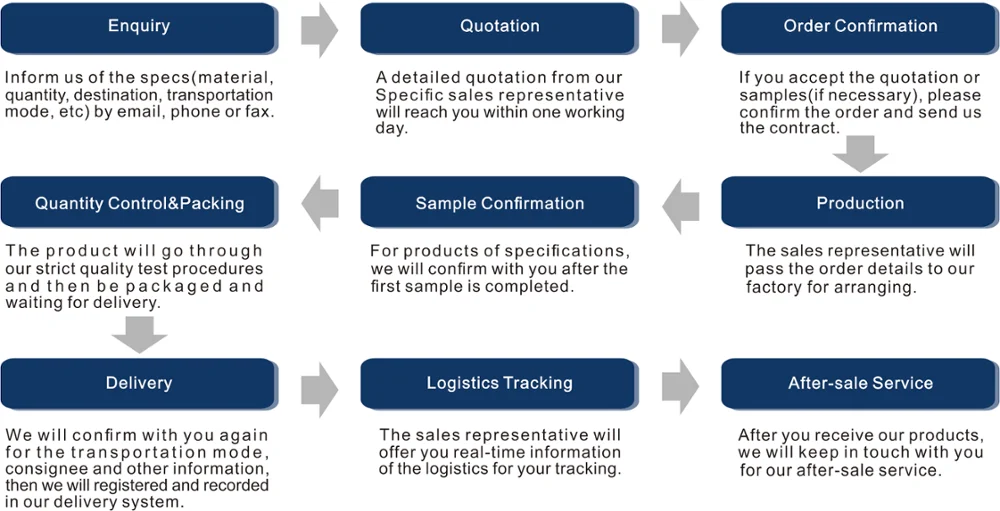

ORDER PROCESS:

PRODUCTION PROCESS:

Cov silicon carbide ceramics crucibles thiab saggers tuaj yeem siv rau ntau yam hmoov sintering, hlau smelting, thiab lwm yam hauv kev lag luam metallurgy, tshuaj lom neeg kev lag luam, iav thiab lwm yam. Shandong Zhongpeng tau cog lus rau kev tshawb fawb thiab kev tsim kho, tsim khoom thiab muag khoom ntawm cov khoom siv zoo silicon carbide, cov khoom tseem ceeb yog cov tshuaj tiv thaiv sintered silicon carbide ceramic beams, cov menyuam tuav, hluav taws kub nozzles, cua txias ducts, sheds, enamel, enamel, thermocouple tiv thaiv Tube, tshav kub txauv raj, radiant tube, radiant tube, radiant tube, radiant tube, tsis muaj raj cantilever paddle, cua sov tube, xuab zeb blasting nozzle, bushing, foob thiab ntau yam kub kub, hnav thiab corrosion resistant silicon carbide ceramic zoo li tus Piece, thiab lwm yam., cov tshuaj tiv thaiv sintered silicon carbide ceramic khoom nrog lub zog siab, siab hardness, hnav tsis kam, kub tsis kam, corrosion kuj, oxidation kuj, thermal poob siab thiab thermal conductivity yog dav siv nyob rau hauv kub ceev thiab thermal conductivity. tub rog, aerospace, nuclear zog, kua siv lead ua thiab metallurgy, tshuaj, machinery, tsheb, ntawv, tshuaj thiab lwm yam teb, cov khoom raug xa tawm mus rau Tebchaws Meskas, Lub Tebchaws Yelemees, Nyiv, Kaus Lim Qab Teb, United Arab Emirates, South Africa, Taiwan thiab lwm yam ntau tshaj 40 lub teb chaws thiab cheeb tsam.

Reaction bonded silicon carbide (SiSiC): Moh lub hardness yog 9.5, nrog zoo heev tsis kam mus yaig thiab corrosion, zoo heev puas-ua hauj thiab anti-oxidation. Nws yog 4 mus rau 5 npaug zog dua nitride bonded silicon carbide. Lub neej kev pabcuam yog 7 mus rau 10 npaug ntev dua li cov khoom siv alumina. MOR ntawm RBSiC yog 5 txog 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua.

Ntim:

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qho ntawm cov loj tshaj plaws silicon carbide ceramic cov khoom siv tshiab hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais tau nrawm, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.