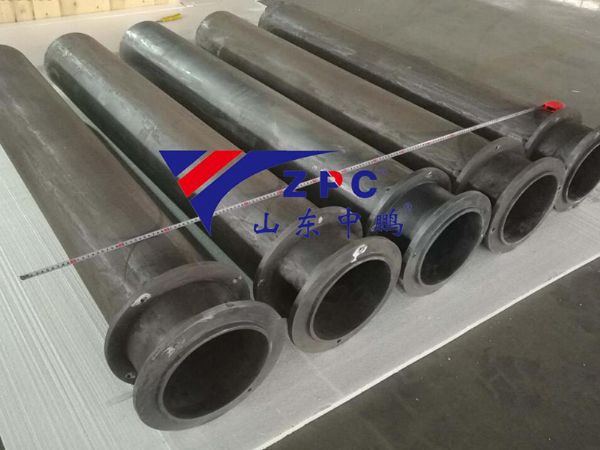

Silicon carbide tiv thaiv tube

Hauv kev lag luam uas huab cua phem ua rau cov khoom siv ncaj ncees,silicon carbide (SiC) cov raj tiv thaivtawm los ua ib qho kev daws teeb meem. Tsis zoo li cov khoom siv tiv thaiv ib puag ncig, SiC tubes sib txuas cov khoom siv qib siab nrog kev ua haujlwm ruaj khov los tiv thaiv cov cuab yeej tseem ceeb thiab cov txheej txheem.Nws muaj qhov zoo hauv qab no:

1. Kev tiv thaiv tsis sib haum xeeb hauv cov xwm txheej phem

SiC cov raj tiv thaiv ua raws li thawj kab ntawm kev tiv thaiv hauv ib puag ncig uas tsis ua haujlwm tsis yog qhov kev xaiv:

(1) Thermal Defense: Tiv thaiv kub mus txog 1600 ° C, tiv thaiv sensors, thermocouples, los yog kev sojntsuam los ntawm cov hlau molten, nplaim taws, thiab ntshav.

(2) Tshuaj Tiv Thaiv: Tiv thaiv corrosion los ntawm acids (xws li sulfuric, hydrochloric), alkalis, thiab reactive gases xws li chlorine los yog sulfur oxides.

Abrasion Resistance: Tiv thaiv cov khoom erosive nyob rau hauv lub txaj fluidized, thee gasifiers, los yog mining ua hauj lwm.

2. Precision thiab ruaj khov rau kev ntsuas tseem ceeb

Hauv cov txheej txheem kev lag luam siab, qhov tseeb yog qhov tseem ceeb. SiC raj txhim khu kev ntseeg tau los ntawm:

(1) Txo txo cov teeb liab cuam tshuam: Cov khoom tsis muaj hluav taws xob tiv thaiv hluav taws xob cuam tshuam hauv hluav taws xob sensors.

(2) Thermal Stability: Zero thermal deformation ua kom muaj kev sib haum xeeb thiab ntsuas qhov tseeb nyob rau hauv qhov kub ceev nrawm.

(3) Gas-Tight Integrity: Impermeable qauv tiv thaiv roj infiltration, tseem ceeb heev rau lub tshuab nqus tsev los yog tswj cov cua.

3. Ua kom Cov Txheej Txheem Tom Ntej SiC cov raj tiv thaiv qhib kev tsim kho tshiab hauv cov haujlwm tshiab:

(1) Hydrogen Economy: Ua haujlwm ruaj khov rau cov sensors hauv hydrogen ntau lawm, cia, thiab roj hlwb, tiv thaiv embrittlement thiab high-pressure H₂ raug.

(2) Semiconductor Manufacturing: Tiv thaiv optical thiab thermal sensors hauv CVD (Chemical Vapor Deposition) reactors los ntawm corrosive precursors xws li silane lossis ammonia.

(3) Kev Tshawb Fawb Txog Kev Tshawb Fawb: Cov ntaub thaiv npog hauv cov foob pob hluav taws cav thiab lub ntiaj teb kev sojntsuam los ntawm huab cua thermal gradients thiab cosmic hluav taws xob.

4. Nqi-Efficiency Los Ntawm Lub Neej Ntev

Thaum SiC cov raj muaj cov nqi siab dua, lawv cov txiaj ntsig kev ua neej rov qab txhais tus nqi:

(1) Txo Cov Sijhawm Ua Haujlwm: Cov hlau tsis zoo lossis quartz lwm txoj hauv kev los ntawm 4-6x nyob rau hauv qhov chaw abrasive lossis acidic, txo qis kev tu tsis tu ncua.

(2) Zero Coating Requirements: Tsis zoo li cov hlau xav tau cov txheej txheem tiv thaiv, SiC cov khoom siv los tshem tawm cov nqi kho mob rov qab.

(3) Reusability: Ciaj sia nyob ntau yam txheej txheem nyob rau hauv daim ntaub ntawv xws li hlau casting los yog iav forming yam tsis muaj degradation.

5. Kev kho kom haum rau cov kev xav tau tshwj xeeb

SiC cov raj tiv thaiv yoog raws cov kev sib tw niche los ntawm kev tsim kho engineering:

(1) Hybrid Designs: Ua ke nrog cov hlau lossis ceramics rau kev sib koom ua ke ntau yam (xws li threaded connectors, flanges).

(2) Kev Hloov Kho Nto: Polished interiors rau kev siv kho qhov muag lossis textured sab nrauv los txhim kho cov cua sov.

(3) Loj Flexibility: Ua los ntawm millimeters (lab-scale reactors) mus rau meters (industrial kilns).

6. Sustainability Alignment

SiC tubes txhawb eco-phooj ywg kev lag luam:

(1) Kev txuag hluav taws xob: Kev ua haujlwm siab thermal txo cov roj siv hluav taws xob ntau txog 20% piv rau cov ntaub thaiv hlau.

(2) Kev txo pov tseg: Lub neej ua haujlwm ntev txiav cov khoom pov tseg los ntawm kev hloov ntau zaus.

(3) Kev txo cov tshuaj lom: tshem tawm qhov xav tau ntawm cov txheej txheem phom sij (xws li, npib tsib xee-raws li alloys) nyob rau hauv ib puag ncig corrosive.

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qhov loj tshaj plaws silicon carbide ceramic cov ntaub ntawv tshiab daws teeb meem hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 mus rau 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais lus yog ceev, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.