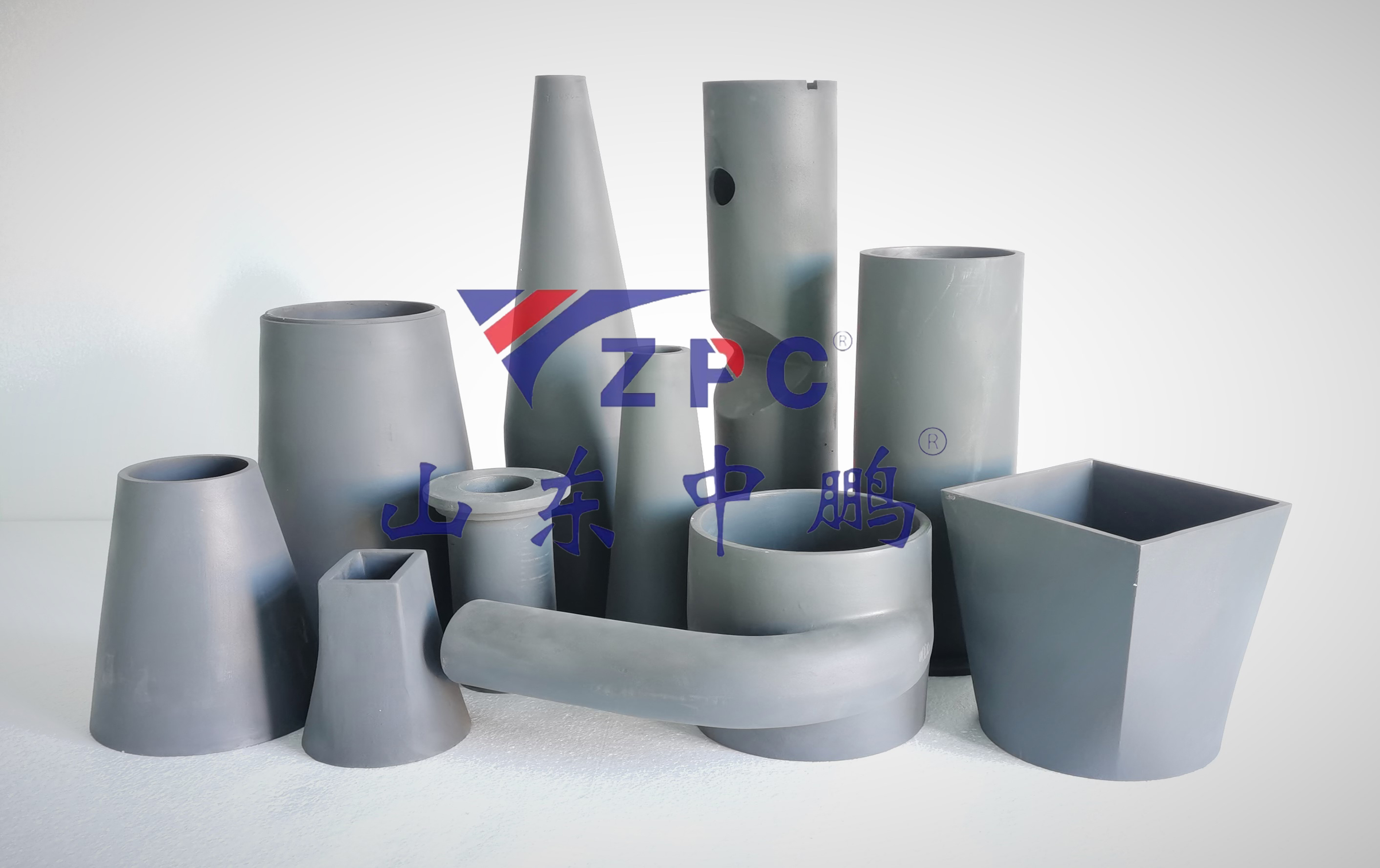

Silicon carbide ceramic liner

Silicon carbide hnav-resistant hauv ob sab phlu

Tsim nta ntawm Silicon Carbide (SiC) Hnav-Resistant Liners:

(1) Streamlined Flow Path Design

Ib tug du, streamlined contour los ntawm inlet mus rau qhov hluav taws xob minimizes txaus tsis kam, ua SiC liners hloov mus rau ntau yam kev siv.

(2) Advanced Atomization

MechanismLiquids yog atomized rau hauv cov tee me me los ntawm kev sib tsoo tangential nrog kev nqaim helical qhov chaw ntawm SiC liner, kom ntseeg tau tias cov tshuaj tsuag tsis sib xws.

(3) Compact, Clog-Free Structure

Ib qho ncaj-dhau, coreless ntws channel tshem tawm cov kev cuam tshuam sab hauv, ua kom cov dej ntws mus rau hauv qhov ntev ntawm cov yeeb nkab thaum tiv thaiv kev thaiv.

(4) Dual Spray Hom rau Txhim Kho Kev Ua Tau Zoo

Txhawb nqa ob qho tib si khoom-cone thiab hollow-cone txau cov qauv, muab cov kaum sab xis dav thiab tiv thaiv kev ua haujlwm rau kev ua haujlwm siab.

Core zoo piv rau lwm yam ntaub ntawv:

(1) Tsis siv neeg hnav tsis kam

Hardness: SiC liners ua tiav Mohs hardness ntawm 9.5 (vs. 8.0 rau alumina ceramics, 6.0 rau high-chromium steel), ua rau lawv tiv taus hnyav hnyav hnav hauv mining slurries, thee tshauv, thiab hmoov hlau.

Lub neej ntev: Kev pab lub neej ntau dua 5-10 × cov khoom siv ib txwm siv (xws li roj hmab lossis polyurethane liners) hauv cov ntawv thov cuam tshuam zoo li pob zeb lossis cov twj slurry.

(2) Corrosion thiab Chemical Inertness

Acid/Alkali Resistance: Resistant sulfuric acid (98%), sodium hydroxide (50%), thiab molten ntsev (xws li NaCl-KCl ntawm 800 ° C), thaum hlau corrode sai thiab polymers degrade.

Zero Contamination: Non-reactive nto ua kom purity nyob rau hauv semiconductor los yog lithium roj teeb ntau lawm, tsis zoo li steel liners nquag ion leaching.

(3) Kev kub ntxhov siab heev

Thermal Resilience: Ua haujlwm tsis tu ncua ntawm 1,600 ° C (vs. alumina's 1,200 ° C txwv) nrog tsawg thermal expansion (CTE: 4.0 × 10⁻⁶ / ℃), tiv thaiv tawg hauv kilns lossis smelting furnaces.

Thermal Shock Resistance: Ua kom muaj kev ncaj ncees nyob rau hauv qhov kub thiab txias (xws li quenching ntawm 1,000 ° C mus rau chav tsev kub), tsis zoo li nkig ceramics.

(4) Kev siv hluav taws xob zoo thiab tsim lub teeb yuag

Kev sib txhuam qis: Polished SiC nto (Ra <0.1 μm) txo cov kua dej los ntawm 30-50% piv rau cov hlau ntxhib, txiav cov nqi siv hluav taws xob.

Txuag Nyhav: Qhov ceev ntawm 3.1 g / cm³ (vs. steel's 7.8 g / cm³) eases installation thiab txhawb nqa lub teeb yuag khoom nyob rau hauv aerospace los yog mobile ua units.

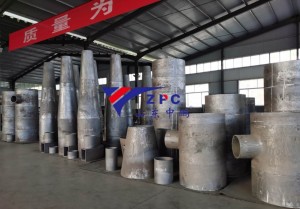

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qhov loj tshaj plaws silicon carbide ceramic cov ntaub ntawv tshiab daws teeb meem hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 mus rau 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais lus yog ceev, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.