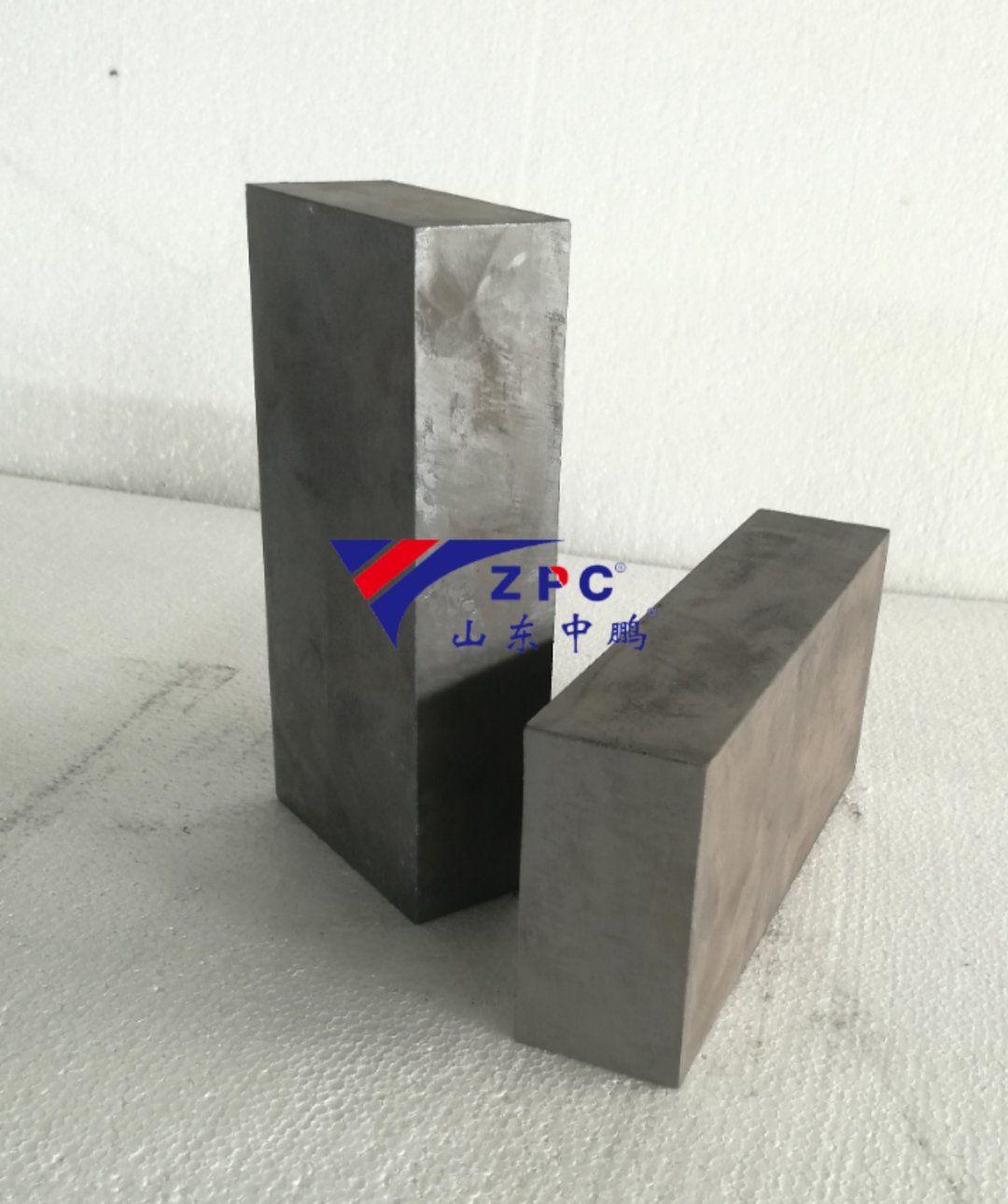

Chaw tsim tshuaj paus (lub Hoobkas) ntawm Silicon Cabide cib, daim hlau, vuas

Silicon Carbide tiv taus ntau yam acids thiab alkalis. Thiab nrog kev ua tau zoo ntawm lub zog siab, siab hardness, siab hnav tsis kam, kub tsis kam, corrosion kuj. Qhov sib txawv ntawm cov duab ntawm qhov tshwj xeeb yog tsim rau mining, petrochemical, metallurgical manufacturing, aerospace thiab nuclear industries, xws li ib puag ncig tshwj xeeb. Peb tuaj yeem ua txhua qhov ntau thiab tsawg raws li cov neeg siv khoom thov.

Hnav tsis kam, kub siab zog thiab corrosion kuj ua Reaction Bonded SiC ib qho khoom siv zoo tagnrho rau cov khoom hnav, xws li cov yeeb nkab liner, cib, vuas, blocks, thiab lwm yam.

| Cov cim ntawm lub cev | Chav tsev | Cov khoom |

| SIC cov ntsiab lus | % | 95-88 : kuv |

| Dawb Si | % | 5 ~ 12 |

| Qhov ntom ntom | g/cm3 | > 3.02 |

| Porosity | % | <0.1 |

| Hardness | Kg / hli 2 | 2400 |

| Coefficient ntawm dabtsi yog khoov zog ntawm 20 degrees Celsius | Mpa | 260 |

| Coefficient ntawm dabtsi yog khoov zog ntawm 1200 degrees Celsius | Mpa | 280 |

| Modulus ntawm elasticity ntawm 20 degrees Celsius | Gpa | 330 |

| Fracture toughness | Mpa * m1/2 | 3.3 |

| Coefficient ntawm thermal conductivity ntawm 1200 degrees Celsius | W/mk | 45 |

| Coefficient ntawm thermal expansion ntawm 1200 degrees Celsius | 10-6mm / hli | 4.5 |

| Coefficient ntawm tshav kub tawg | <0.9 | |

| Max. Ua haujlwm kub | ºC | <1380 |

Silicon Carbide SiC (SiSiC / RBSiC) Nta:

Abrasion / Corrosion kuj

Cov yam ntxwv zoo thermal shock

Zoo heev oxidation tsis kam

Kev tswj qhov zoo ntawm cov duab zoo

High thermal conductivity

Kev ua tau zoo dua

Lub neej ntev ntawm kev hloov / rov tsim dua

Kev tiv thaiv corrosion

Superior Resistance rau hnav

Lub zog ntawm qhov kub thiab txias txog li 1380 ° C

Silicon carbide daim hlau siv:

SiC silicon carbide phaj thiab cov vuas yog ib hom tshwj xeeb ceramic phaj yog dav siv hauv ntau cov khoom lag luam:

Kev lag luam mining, tshuab kev lag luam, tshuaj lom neeg kev lag luam, Crystallite iav kev lag luam, sib nqus cov ntaub ntawv kev lag luam, metallurgy, metallurgy kev lag luam, ntawv kev lag luam, roj av kev lag luam, kiln, thiab lwm yam.

Customized silicon carbide cov khoom, cov duab muaj: daim hlau, cib, vuas, radian phaj, ntsia hlau, tiaj phaj, ncaj yeeb nkab, tee kav, nplhaib, luj tshib, lub khob hliav qab cyclone thiab hais txog.

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qho ntawm cov loj tshaj plaws silicon carbide ceramic cov khoom siv tshiab hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais tau nrawm, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.