Silicon carbide kab

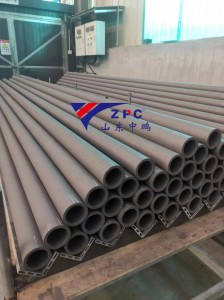

Reaction-sintered silicon carbide (R-SiC) ceramic rollerstau tshwm sim los ua cov khoom tseem ceeb hauv cov txheej txheem thermal ua niaj hnub, tshwj xeeb tshaj yog ua tau zoo hauv kev tsim cov roj teeb lithium, cov khoom siv ceramics siab heev, thiab cov khoom siv hlau nplaum sib nqus sintering. Cov chais tshwj xeeb no redefine cov qauv kev ua tau zoo hauv high-temperature industrial furnaces los ntawm kev daws cov teeb meem tseem ceeb hauv thermal stability thiab mechanical durability.

Kev ua haujlwm thermal tsis sib xws

Tsim los ua haujlwm tsis tu ncua ntawm 1450-1600 ° C - siab dua li ib txwm alumina rollers - R-SiC rollers tswj qhov ntsuas qhov tseeb txawm tias nyob rau hauv huab cua kub caij tsheb kauj vab. Lawv tshwj xeeb microstructure enables:

• Kev hloov hluav taws xob nrawm nrawm (± 5 ° C hla cov menyuam ntev)

• Nrog rau 100+ thermal shock cycles (1400 ° C ↔ chav tsev kub)

• Zero creep deformation ntawm qhov kub thiab txias

Cov ntawv thov tseem ceeb rov txhais dua

1. Lithium roj teeb ntau lawm

- Kev sib raug zoo meej rau cov khoom siv electrode sintering

- Kev tswj tsis pub muaj kab mob ntawm NMC / LFP cathodes

- Kev ua haujlwm ruaj khov hauv kev txo cov huab cua

2. Advanced Ceramics Processing

- Warp-free kev txhawb nqa rau cov vuas loj (txog 1.5 × 3m)

- Kev tswj ceev ceev hauv cov khoom siv huv huv glazing kab

- Tsis-kos nto tag (Ra <0.8μm)

3. Kev tsim khoom siv hlau nplaum

- Kev sib hloov tsis muaj kev vibration rau kev taw qhia ferrite sintering

- Tshuaj inertness nyob rau hauv hydrogen-nplua nuj ib puag ncig

Kev Ua Haujlwm Zoo

Load Capacity: Txhawb 3-5 × ntau dua qhov hnyav rau ib chav tsev ntev vs. hlau alloy rollers

Deformation Resistance: Khaws <0.05mm / m ncaj nraim tom qab 10,000 teev ua haujlwm

Zog Efficiency: 18-22% txo cov hluav taws xob siv hluav taws xob los ntawm kev ua kom zoo tshaj plaws ntawm cov cua sov

Cross-Industry Compatibility: Adaptable rau shuttle kilns, multi-layer roller hearths, thiab hybrid tunnel furnaces

Economic Sustainability

Thaum xav tau 30-40% kev nqis peev ntau dua li cov qauv siv, R-SiC cov kev daws teeb meem qhia:

- 70% ncua kev pab cuam ntev (5-7 xyoo vs. 2-3 xyoos)

- 90% recyclability los ntawm thermal reclamation txheej txheem

- 60% txo tus nqi txij nkawm los ntawm kev puas tsuaj-resistant nto

Yav Tom Ntej-Ready Design

Niaj hnub nimno R-SiC rollers tam sim no suav nrog:

- Laser-engraved nrhiav grooves rau automated ntau lawm kab

- Customizable porosity rau tej huab cua permeability

- Integrated thermal sensors rau kev ua haujlwm ntse kiln

Cov kev txhim kho thev naus laus zis no txoj haujlwm cov tshuaj tiv thaiv-sintered silicon carbide rollers ua cov khoom tseem ceeb hauv cov khoom siv hluav taws xob tom ntej, ua rau cov tuam txhab ua kom muaj kev tswj xyuas qhov kub thiab txias dua, cov khoom lag luam zoo sib xws, thiab kev ua haujlwm ruaj khov nyob thoob plaws ntau qhov kev lag luam siab.

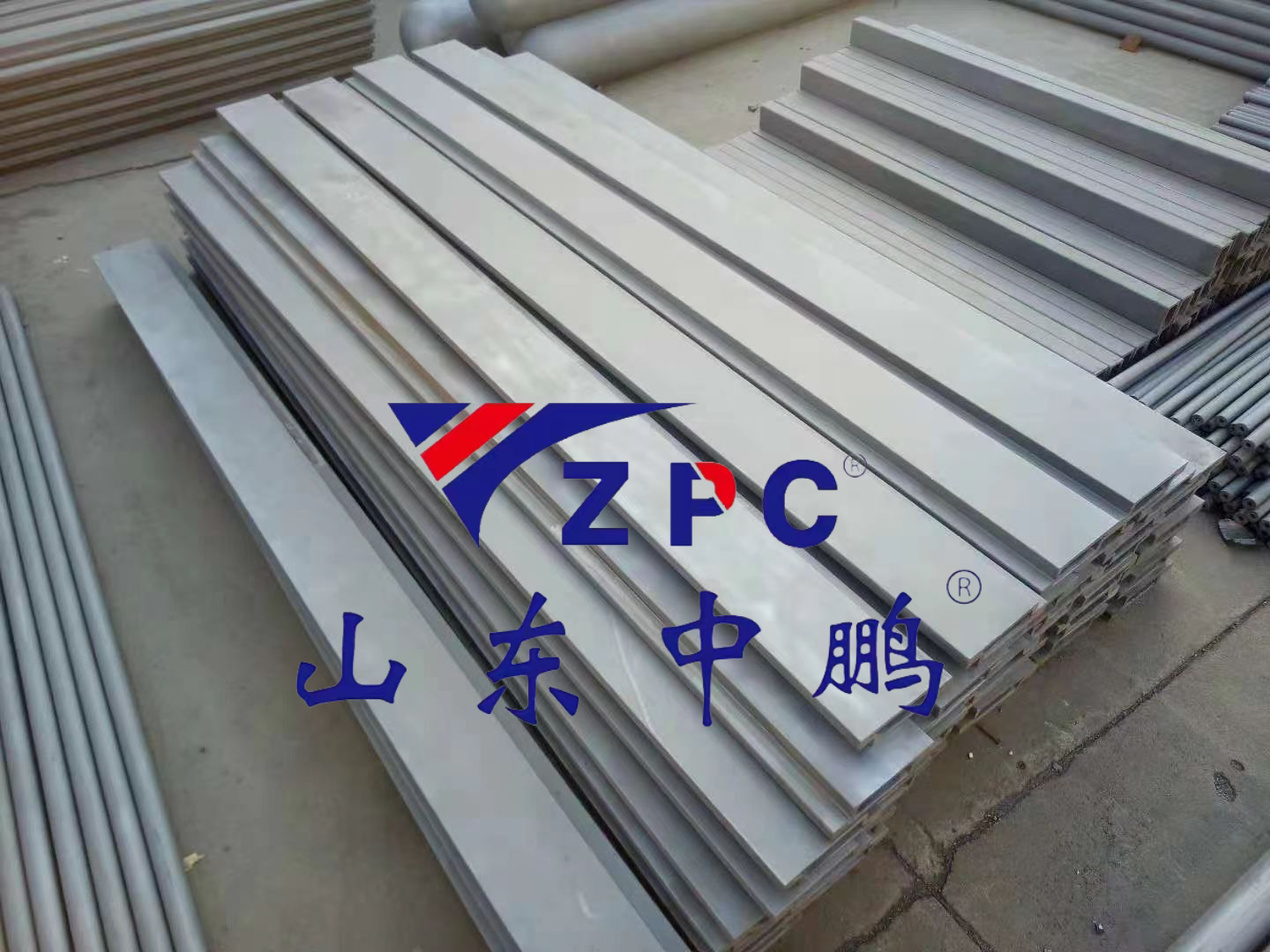

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qhov loj tshaj plaws silicon carbide ceramic cov ntaub ntawv tshiab daws teeb meem hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 mus rau 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais lus yog ceev, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.