Qauv ntawm SiC FGD Nozzle, Tangential Swirl FGD Nozzle

Reaction bonded silicon carbide (SiSiC): Moh lub hardness yog 9.5, nrog zoo heev tsis kam mus yaig thiab corrosion, zoo heev puas-ua hauj thiab anti-oxidation. Qhov ntau thiab tsawg, nws yog 4 mus rau 5 npaug zog dua nitride bonded silicon carbide. Lub neej kev pabcuam yog 7 mus rau 10 npaug ntev dua li cov khoom siv alumina. MOR ntawm RBSiC yog 5 txog 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd (ZPC) yog cov chaw tsim khoom loj tshaj ntawm SiSiC FGD nozzles hauv Suav teb. ZPC yog cov chaw muag khoom ruaj khov ntawm CHINA POWER GROUP, thiab muaj kev koom tes nrog cov neeg siv khoom thoob ntiaj teb.

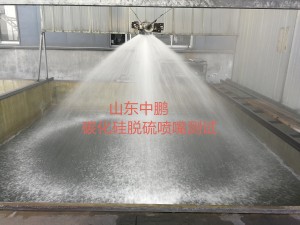

Lub slurry nkag mus rau lub swirl chamber ntawm lub nozzle los ntawm tangential kev taw qhia. Tom qab ntawd, cov kua yog ejected los ntawm lub nozzle qhov ntawm txoj cai kaum mus rau inlet kev taw qhia. Rau Hollow cone vortex nozzle, lawv yog cov kev sib xyaw ua ke hauv kev tsim khoom. Nws cov duab yog hollow conical uas nws qhov chaw txhaj tshuaj yog ncig. Lub kaum sab xis thiab ntws ntawm Hollow cone vortex nozzle tuaj yeem tsim raws li cov neeg siv khoom xav tau. Cov tshuaj tsuag ntawm hollow cone vortex nozzle zoo thiab sib xws hauv txoj kab uas hla. Vim nws qhov loj vortex channel, lub nozzle tsis yooj yim rau ntsaws. Cov vortex nozzles yog Hollow cone tangential nozzles, Tag nrho lub khob hliav qab tangential nozzles, Loj dawb passage ob hollow cone tangential nozzles.

Daim ntawv sib txuas: winding adhesive flanged kev sib txuas thiab threaded kev sib txuas.

Txau nyhuv: 90 °, 120 °

Nozzle kuaj:

Daim ntawv thov:

| Cov cua txias ceev ntawm cov cua kub cua kub |

| Lub tshuab ntxhua khaub ncaws |

| Flue gas plua plav tshem tawm |

| Kev ntub dej desulphurization |

| Leaching pej thuam |

| Coke quenching |

| Ntxuav thiab bleaching |

| Tshuaj tsuag ntauwd |

| Cov dej txias thiab fractionating rau ntauwd txau |

| Defoaming |

Factory Saib:

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qho ntawm cov loj tshaj plaws silicon carbide ceramic cov khoom siv tshiab hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais tau nrawm, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.