RBSiC (SiSiC) Rollers thiab kab teeb hauv kiln

1. Sintering Theory

Reaction bonded SiC (sisic) yog tsim los ntawm α-SiC hmoov, graphite hmoov, sib tov additives thiab organic nplaum tus neeg sawv cev. Lub cev sib tov yog extruded thiab ces sau rau hauv pwm nrog silicon hmoov. Sintered nyob rau hauv lub tshuab nqus tsev cua sov rauv ntawm 1680 ° C, yaj silicon hmoov reacts nrog cov pa roj carbon nyob rau hauv lub cev, thaum kawg tsim β-Sic vim lub tshav kub ntawm cov tshuaj tiv thaiv.

2. Khoom nta

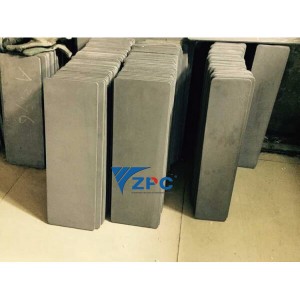

Nrog rau cov yam ntxwv ntawm lub zog siab, kub tsis kam, siab hardness, siab hnav tsis kam, corrosion kuj, oxidation kuj, thermal shockresistance, zoo thermal conductivity thiab thermal efficiency.Lub neej yog ntau tshaj 10 zaug ntawm stainless hlau kav.

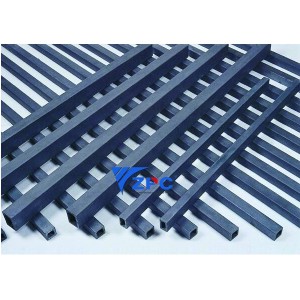

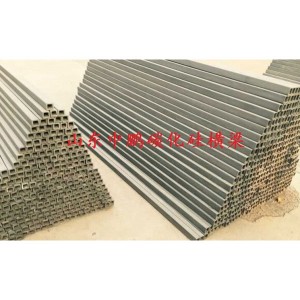

Silicon carbide beams thiab rollers yog siv los ua cov thav ntawv hauv cov porcelain tsim kiln, thiab uas tuaj yeem hloov cov oxide sib txuas nrog silicon phaj thiab mullite ncej vim lawv muaj qhov zoo zoo xws li txuag chaw, roj, lub zog thiab luv luv lub sijhawm tua, thiab lub neej ntawm cov ntaub ntawv no yog ob peb zaug ntawm lwm tus nws yog qhov zoo tagnrho cov rooj tog zaum.

Beams nrog siab - kub bearing peev xwm loj, ntev siv tsis muaj dabtsi yog khoov deformation, tshwj xeeb tshaj yog haum rau tunnel kilns, shuttle kiln, nyob rau hauv ob - txheej rau cov menyuam kiln thiab lwm yam muaj furnace load - bearing qauv ntawm ncej.

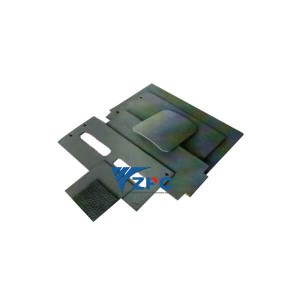

Cov koom haum siv rau txhua hnub - siv cov ceramics, cov plooj (porcelain) huv, Lub Tsev Ceramic, cov khoom siv hlau nplaum thiab kub kub firing cheeb tsam ntawm cov menyuam kiln.

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qho ntawm cov loj tshaj plaws silicon carbide ceramic cov khoom siv tshiab hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 txog 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais tau nrawm, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.