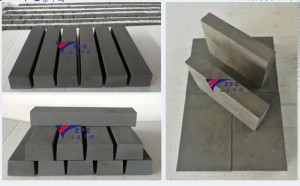

RBSC Silicon Carbide Ceramic Vuas

RBSC Silicon Carbide Ceramic Vuastau tshwm sim los ua qhov kev daws teeb meem zoo tshaj plaws rau kev sib ntaus sib tua hnav thiab corrosion hauv kev xav tau kev lag luam ib puag ncig. Cov vuas luaj ceramic thiab hauv ob sab phlu xa cov kev ua tau zoo tsis sib xws hauv cov khoom siv tuav, txuas cov cuab yeej siv lub neej thaum txhim kho kev ua haujlwm zoo thoob plaws cov txheej txheem tseem ceeb.

Engineering Superiority

Peb precision-tsim silicon carbide (SiC) Cheebtsam ua tau zoo los ntawm cov khoom siv tshwj xeeb:

- Mohs Hardness 9.5 (13 ntawm qhov hloov tshiab) rau kev hnav tsis kam

- 4–5 × ntau dua tawg toughness vs. nitride-bonded SiC lwm

- 5-7 × ntev kev pab cuam lub neej piv rau cov tsoos alumina hauv ob sab phlu

- Tshuaj inertness tiv thaiv acids, alkalis, thiab organic solvents (pH 0-14)

- Thermal stability tswj kev ncaj ncees ntawm -60 ° C txog 1650 ° C

Customized Protection Solutions

Muaj nyob rau hauv thicknesses los ntawm 8-45 hli, peb cov ntaub ntawv ceramic hloov mus rau ntau hom kev ua haujlwm:

- Impact-resistant configurations rau chutes thiab hoppers

- Tsawg-kev sib txhuam qhov chaw rau cov tshuab conveyor

- High-purity qib rau zaub mov / tshuaj siv

- Hluav taws xob insulating variants rau qhov chaw tawg

Kev Ua Haujlwm-Driven Applications

1. Cov Khoom Siv Ua Haujlwm

- Slurry pipelines nrog 90% txo erosion

- Mining trommels nrog 3 × txuas ntxiv kev pabcuam

- Cement cog cyclones muaj sia nyob 50,000+ teev ua haujlwm

2. Cov khoom siv ua haujlwm

- Coal pulverizer linings tiv thaiv 120 m / s particle cuam tshuam

- Tshuaj reactor cov hlab ntsha tuav cov xov xwm corrosive

- Steel cog ductwork withstanding abrasive ya tshauv

3. Cov Txheej Txheem Tshwj Xeeb

- Rotor hniav txheej rau centrifugal separators

- Hnav daim hlau rau biomass ua

- Custom-shaped inserts rau complex geometry

Kev cuam tshuam nyiaj txiag

Kev hloov mus rau silicon carbide hauv ob sab phlu qhia tau tias muaj txiaj ntsig zoo:

- 60-80% txo qis hauv lub sijhawm tsis tau npaj tseg

- 45% txo tus nqi tu lub neej

- 30% kev txuag hluav taws xob los ntawm cov khoom siv tau zoo

- 90% rov ua dua ntawm cov khoom hnav

Installation & Adaptability

Engineered rau seamless kev koom ua ke:

- Modular pobzeb systems nrog interlocking designs

- Lub zog muaj zog epoxy lossis mechanical fixation

- On-site machining thiab retrofitting kev pab cuam

- Real-time saib xyuas kev sib raug zoo

Yav Tom Ntej-Ready Innovations

Lwm tiam silicon carbide linings suav nrog:

- Gradient density structures rau kev cuam tshuam kev nqus

- Kev kho tus kheej lubricating nto

- RFID-enabled coj taug qab

- Hybrid ceramic-metal composite systems

Los ntawm kev ua haujlwm mining mus rau cov chaw ua tshuaj lom neeg, silicon carbide ceramic linings sawv cev tus qauv tshiab hauv kev tiv thaiv kev lag luam. Lawv qhov sib xyaw ua ke ntawm cov neeg kho tshuab resilience, tshuaj lom neeg ruaj khov, thiab thermal endurance hloov cov cuab yeej ua haujlwm - txo cov nqi ntawm lub neej thaum txhim kho kev ntseeg siab hauv lub ntiaj teb kev ua haujlwm zoo tshaj plaws.

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qhov loj tshaj plaws silicon carbide ceramic cov ntaub ntawv tshiab daws teeb meem hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 mus rau 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais lus yog ceev, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.