FGD Absorber slurry spray nozzles

WET FLUE GAS DESULFURIZATION (FGD) NOZZLE nrog txiv qaub / LIMESTONE SLURRY

Nta

Desulfurization efficiency: tshaj 99%

Muaj peev xwm: tshaj 98%

Engineering tsis nyob ntawm ib qho chaw tshwj xeeb

Cov khoom lag luam

Unlimited ib feem load ua haujlwm

Txoj kev nrog cov neeg siv ntau tshaj plaws hauv ntiaj teb

Purification ntawm flue roj los ntawm txiv qaub suspension

Rau qhov ntub dej desulphurisation ntawm flue roj, nws yog dhau los ntawm ib qho absorber (scrubber). Cov kua txiv qaub uas muaj nyob rau hauv lub absorber (limestone los yog txiv qaub mis) reacts nrog sulfur dioxide los ntawm flue gas. Qhov zoo dua qhov kev hloov loj, qhov ua tau zoo dua qhov desulphurisation yog.

Tib lub sijhawm nrog kev nqus, cov pa roj flue saturated nrog dej vapor. Lub npe hu ua "cov pa huv" feem ntau yog tawm ntawm lub qhov cub ntub dej los yog cov cua txias ntauwd. Cov dej yog li poob rau cov txheej txheem yuav tsum tau hloov. Cov txiv qaub slurry pumped nyob rau hauv kev ncig yog khaws cia tshuaj nquag los ntawm kev rov ua kom cov dej ntws ib nrab thiab hloov nws nrog cov tshuaj tiv thaiv tshiab. Cov dej ntws ntws tawm muaj gypsum, uas - yooj yim - yog cov khoom siv tshuaj tiv thaiv ntawm txiv qaub thiab sulfur thiab tuaj yeem ua lag luam tom qab dewatering (xws li gypsum phab ntsa hauv kev tsim kho).

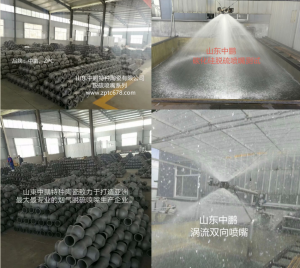

Tshwj xeeb ceramic nozzles yog siv los txhaj cov kua qaub rau hauv lub absorber. Cov nozzles tsim ntau cov tee me me los ntawm lub twj tso kua mis raug tshem tawm thiab yog li cov tshuaj tiv thaiv loj heev rau kev hloov pauv loj. Cov khoom siv ceramic tso cai rau lub neej ua haujlwm ntev txawm hais tias qhov kev tshem tawm cov txiv qaub nrog cov ntsiab lus gypsum muaj cov khoom abrasive. Hauv kev tsim qauv peb muab qhov tseem ceeb heev rau cov seem dawb, kom cov impurities me me hauv qhov raug ncua tsis tuaj yeem teeb tsa lub nozzles. Rau kev lag luam kev lag luam, cov nozzles tuaj yeem hloov mus rau qhov ua tau zoo tshaj plaws ntawm lub twj tso kua mis. Lub nozzle tuaj yeem teev rau (yuav luag) txhua qhov kev sib tw engineering. Ntxiv rau tag nrho lub khob hliav qab thiab hollow-cone nozzles nyob rau hauv ntau yam tshuaj tsuag cov ces kaum thiab txaus tus nqi, ZPC nozzle nrog patented twist them nyiaj kuj muaj.

Qhov chaw nqus dej muaj ntau theem ntawm lub nozzles thiab kab rov tav ntsia hlau cais qhov system, thiaj li yuav rov qab cov tee dej zoo nqa mus rau hauv cov dej ntws mus rau cov txheej txheem. Nrog peb cov kev ua tau zoo droplet separators koj tuaj yeem ua rau koj cov nroj tsuag muaj txiaj ntsig.

Cov khib nyiab hauv qhov raug ncua tuaj yeem ua rau cov deposits, piv txwv li nyob rau hauv lub droplet separator, nyob rau hauv lub inlet duct los yog nyob rau hauv cov kav dej, uas yuav ua rau muaj teeb meem nyob rau hauv lub lag luam. Txij li cov dej ib txwm thim tawm ntawm lub voj voog los ntawm evaporation, dej yuav tsum tau pub rau hauv lub absorber, uas tuaj yeem thiab yuav tsum tau siv los ntxuav. ZPC tus nplaig nozzles tau ua pov thawj lawv tus kheej rau kev ntxuav cov pa roj nkag. ZPC tag nrho lub khob hliav qab nozzles feem ntau yog siv los ntxuav cov dej sib cais.

Cov yas (piv txwv li rau cov kav dej) thiab roj hmab (xws li gaskets, roj hmab hauv ob sab phlu, thiab lwm yam) feem ntau yog siv rau hauv lub absorber uas nws qhov kub thiab txias tsis kam yog qis dua qhov kub ntawm cov pa roj uas tsis muaj cua sov. Nquag, qhov raug tshem tawm hauv lub voj voog ua kom cov pa roj flue txaus, tab sis yog tias, piv txwv li, lub twj tso kua mis pub raug tshem tawm, cov yas thiab cov roj hmab tuaj yeem raug puas tsuaj. Cov me me tshwj xeeb-alloy hlau nozzles tau ua pov thawj tias lawv muaj nqis ntawm no, uas ua kom txias thaum lub sijhawm no thiab yog li tiv thaiv kev nqis peev ntawm flue gas desulphurisation cog.

Reaction bonded silicon carbide (SiSiC): Moh lub hardness yog 9.2, nrog zoo heev tiv taus yaig thiab corrosion, zoo heev puas-ua hauj thiab anti-oxidation. Nws yog 4 mus rau 5 npaug zog dua nitride bonded silicon carbide. Lub neej kev pabcuam yog 7 mus rau 10 npaug ntev dua li cov khoom siv alumina. MOR ntawm RBSiC yog 5 mus rau 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua.

Shandong Zhongpeng Tshwj Xeeb Ceramics Co., Ltd yog ib qhov loj tshaj plaws silicon carbide ceramic cov ntaub ntawv tshiab daws teeb meem hauv Suav teb. SiC technical ceramic: Moh lub hardness yog 9 (New Moh's hardness yog 13), nrog zoo heev tiv taus yaig thiab corrosion, zoo heev abrasion - kuj thiab anti-oxidation. SiC khoom lub neej kev pab cuam yog 4 mus rau 5 zaug ntev dua 92% alumina khoom. MOR ntawm RBSiC yog 5 mus rau 7 npaug ntawm SNBSC, nws tuaj yeem siv rau cov duab ntau dua. Cov txheej txheem hais lus yog ceev, kev xa khoom yog raws li tau cog lus tseg thiab qhov zoo yog qhov thib ob. Peb ib txwm pheej sim sim peb lub hom phiaj thiab muab peb lub siab rov qab los rau zej zog.