amathayela e-ceramic wezimboni angagugi, amalayini

![]()

I-Reaction bonded silicon carbide (i-SiSiC noma i-RBSIC) iyimpahla efanelekile engagqoki, eyi-

ifaneleka ngokukhethekile i-abrasive eqinile, izinhlayiya eziqinile, ukuhlukaniswa, ukugxila, ukuphelelwa amandla kwamanzi kanye ne-

eminye imisebenzi. Isetshenziswa kabanzi embonini yezimayini, embonini yensimbi, embonini yokucubungula amakhorali, amakhemikhali

imboni, imboni yokwenza izinto ezingavuthiwe, ukuvala uphawu ngemishini, ukwelashwa kwe-sandblasted engaphezulu kanye nesibonisi njll.

Ngenxa yokuqina okuhle kakhulu nokumelana ne-abrasive, kungavikela ngempumelelo ingxenye lapho kudingeka khona ukugqokwa

ukuvikelwa, ukuze kunwetshwe impilo yesevisi yemishini.

Ungawahlonza kanjani futhi uwathole kanjani amapuleti, amathayili, ama-liner wekhwalithi ephezulu we-silicon carbide?

Amathayili we-silicon carbide angagugi, ama-liner, amapayipi aya ngokuya asetshenziswa kabanzi embonini yezimayini.

Amaphuzu alandelayo awereferensi yakho:

1. Ifomula kanye nenqubo:

Kunezinhlobo eziningi ze-SiC emakethe. Sisebenzisa ukwakheka okuyiqiniso kwesiJalimane. Ekuhlolweni kwaselabhorethri kwezinga eliphezulu, ukulahlekelwa komkhiqizo wethu I-Erosion ㎝³ ingafinyelela ku-0.85 ± 0.01;

2. Ukuqina:

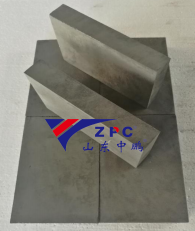

Amathayela e-SiC akhiqizwa ku-ZPC: ubulukhuni be-Mohs obusha: 14.55 ± 4.5 (MOR, psi)

3. Ukuminyana:

Ibanga lokuminyana kwethayela le-ZPC SiC licishe libe ngu-3.03+0.05.

4. Osayizi Nobuso:

Amathayela e-SiC akhiqizwa ku-ZPC ngaphandle kokuqhekeka nezimbotshana, anezindawo eziyisicaba kanye nemiphetho eqinile namakhona.

5. Izinto zangaphakathi:

Ama-liner/thayela angavimbeli i-silicon carbide anezinto ezisetshenziswayo zangaphakathi nezangaphandle ezinhle futhi ezifanayo.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Imininingwane:

| Into | Iyunithi | Idatha |

| Izinga lokushisa isicelo | ℃ | 1380 ℃ |

| Ukuminyana | G/cm3 | 3.02 |

| I-porosity evulekile | % | <0.1 |

| Amandla okugoba -A | Mpa | 250 (20℃) |

| Amandla okugoba -B | I-MPa | 280 (1200℃) |

| I-modulus ye-elasticity-A | I-GPa | 330(20℃) |

| I-modulus yokuqina -B | I-GPa | 300 ( 1200 ℃ ) |

| I-Thermal conductivity | W/mk | 45 (1200℃) |

| I-coefficient yokwanda kwe-thermal | K-1 × 10-6 | 4.5 |

| Ukuqina | / | 13 |

| I-alkaline evikela i-asidi | / | kuhle kakhulu |

■Umumo Otholakalayo nosayizi:

Ubukhulu: kusuka ku-6mm kuya ku-25mm

Umumo Ojwayelekile: Ipuleti le-SISIC, i-SISIC Pipe, i-SiSiC Three Links, i-SISIC Elbow, i-SISIC Cone Cyclone.

Phawula: Abanye osayizi nokuma kuyatholakala uma kuceliwe.

■Ukupakishwa:

Ebhokisini lebhokisi, elipakishwe kuphalethi yokhuni efuthiweyo enesisindo senetha 20-24MT/20′FCL.

■Izinzuzo ezibalulekile:

1. Ukumelana nokugqokwa okuhle kakhulu, ukumelana nomthelela kanye nokumelana nokugqwala;

2. I-flatness enhle kakhulu nokumelana nokushisa okuhle kakhulu kuze kufike ku-1350 ℃

3. Ukufakwa kalula;

4. Impilo yesevisi ende (cishe izikhathi eziyisi-7 kune-alumina ceramic futhi izikhathi eziyishumi kune-

i-polyurethane

Iphethini yokuhuzuka komthelela we-engeli Umhuzuko wokushelela we-engeli ephansi

Uma ukugeleza kwezinto ezilimazayo kufinyelela endaweni egugileyo nge-engeli engashoni noma kudlula ngokuhambisana nayo, uhlobo lokugqokwa okwenzeka lapho kungqubuzana kubizwa ngokuthi i-sliding abrasion.

I-silicon carbide ceramics ethuthukisiwe ihlinzeka ngokumelana nokuguga kanye nokumelana nokugqwala kwamathayela e-ceramic kanye nolwelwesi. Le mikhiqizo ifakazelwe ukuguga kwemishini ekudluliseni, ekucubunguleni nasekugcinweni. Amathayili ethu angakhiqizwa ngokuqina kusuka ku-8 kuye ku-45mm. kubalulekile ukuqinisekisa ukuthi ungathola imikhiqizo edingekayo. I-SiSiC: Ukuqina kuka-Moh kungu-9.5 (ukuqina kwe-New Moh kungu-13), enokumelana okuhle kakhulu nokuguguleka nokugqwala, ukuhuzuka okuhle kakhulu – ukumelana ne-anti-oxidation. Inamandla izikhathi ezi-4 kuya kwezi-5 kune-nitride eboshiwe i-silicon carbide. Impilo yesevisi yinde izikhathi ezi-5 kuya kweziyi-7 kunempahla ye-alumina. I-MOR ye-RBSiC izikhathi ezi-5 kuye kweziyi-7 kune-SNBSC, ingasetshenziselwa izimo eziyinkimbinkimbi. Indwangu ye-ceramic engazweli iyasiza ukwenza ngcono ukusebenza kokukhiqiza, ukusebenza kahle, ukuncishiswa kwezindleko zokulungisa kanye nokwenyuka kwenzuzo.

Izitsha zobumba eziqondile zinolwazi lwezinto ezibonakalayo, ubuchwepheshe obusetshenzisiwe kanye namakhono wobunjiniyela. Lokhu kungaqinisekisa ngempumelelo ukuthi izixazululo ezingcono kakhulu zinikezwa amakhasimende ethu. Amathayela e-silicon carbide ceramic kanye nolwelwesi kuvame ukusetshenziswa ezinhlelweni ezifana neziphepho, amashubhu, ama-chute, ama-hoppers, amapayipi, amabhande okuthutha kanye nezinhlelo zokukhiqiza. Ohlelweni, kunezinto ezihambayo ezishelelayo phezulu. Lapho into ishelela entweni, iguga kancane kancane izingxenye kuze kugcine kungasali lutho. Ezimweni zokugqoka okuphezulu, lokhu kungenzeka kaningi futhi kubangele izinkinga eziningi ezibizayo. Isakhiwo esiyinhloko sigcinwa kusetshenziswa into eqinile kakhulu, njenge-silicon carbide ceramics kanye ne-alumina ceramics njengolwelwesi lomhlatshelo. Ngasikhathi sinye, i-silicon carbide ceramics ingabekezelela ukuguga isikhathi eside ngaphambi kokuba idinga ukushintshwa, impilo yesevisi ye-silicon carbide ceramic inde izikhathi ezi-5 kuya kweziyi-7 kunempahla ye-alumina.

Gqoka Amathayela E-Ceramic Engazweli We-Silicon Carbide Nezakhiwo Zokulala:

Ukumelana namakhemikhali

Ivikela ugesi

Ukumelana nokuguguleka kwemishini nokumelana nemihuzuko

Engashintshwa

Izinzuzo zamathayela Angavimbeli Wear & Linings:

Ingasetshenziswa lapho kudingeka khona ukubekezelelana okuqinile noma izintambo ezincane

Ingasetshenziswa ukuvusa kabusha izindawo ezijwayele ukuguga

Ingasetshenziswa ngezindlela eziningi zokunamathisela ezifana nokushisela nokunamathiswa

Ngokwezifiso yakhelwe izinhlelo zokusebenza ezithile

Imelana nokugqwala kakhulu

Isixazululo sokunciphisa ukugqokwa okungasindi

Ivikela izingxenye ezihambayo ezingaphansi kwezindawo ezigugile kakhulu

Idlula kakhulu futhi idlula izixazululo zokunciphisa ukugqokwa

Izinga lokushisa eliphezulu kakhulu elifinyelela ku-1380°C

I-Iron ne-steel plant: 1, i-sintering machine drum mixer lining 2, irabha egoqwe isigubhu se-ceramic 3, i-fan impeller 4, i-disc feeder, i-dry material trough 5, i-coke hopper, i-converter bin, i-coke bin, umqoqi wothuli lwe-cyclone.

2, Imboni yamandla: 1. Indawo yokugaya ibhola, i-volute ye-mill, i-medium speed mill outlet, indololwane yepayipi le-cyclone, i-cyclone dust collector, i-silo, i-hopper 2, i-hopper yamalahle, isihlukanisi sempushana esimahhashi nesicolekileyo, indawo yokukhipha amalahle, i-hopper yamalahle edlulisa amalahle, i-hopper yamalahle yebhuloho, indawo ye-coal outlet ne-milllet. yesihlukanisi sempushana esimahhadlahhadla nesicolekileyo, isikhipha esikhipha impushana eningi 4 Izinhlobo ezahlukene zamanje eziqondile, ezijiyayo eziminyene futhi ezincibilikisa izibasi ezikwazi ukumelana nezinga lokushisa eliphezulu kumabhayela abaswa amalahle; amapayipi nendololwane ze-ceramic ezigqoke kakhulu, izibasi ze-ceramic, amafeni e-ceramic, ama-impeller e-ceramic, ama-valve e-ceramic, njll.; izingxenye ezihlukahlukene ezingagugi ezifana namabhola okugaya, imikhono ye-roller, ama-disc okugaya, ama-disc tile, izindandatho zokugaya, amabhola we-nozzle nezinye izingxenye ezingagqoki zezigayo zamalahle ezisheshayo; amapayipi, i-damper engagugi kanye nabalandeli bemininingwane ehlukahlukene yokuhlikihla nokususa umlotha; amabhola Zonke izinhlobo zesigayo zinamathayela (noma cha) amabhawodi olayini, ipuleti le-lining, ipayipi elivunguzayo, iringi yegiya, ibhola lensimbi eliphansi le-chromium alloy, njll.; isondo elishayayo, ipuleti elishayayo, ihhuku eligadayo, izikhali, isihlukanisi, ipayipi legesi elishisa izikhotha esithandweni somlilo, njll. yesigayo samalahle esiphephetha umlilo; izesekeli ezidingekayo ezinhlobonhlobo zemishini yokuchoboza.

3, Isigayo samaphepha: 1. Ipayipi lamalahle eliputshuziwe

Imikhiqizo namasevisi amakhulu: 1. Amapayipi e-ceramic angagugi ezimbonini: zonke izinhlobo ze-ceramic ukumelana nokuguga futhi ukumelana nokushisa okuphezulu okufakwe amalahle aputshuziwe, izisila, udaka lwe-slag, ipayipi lokuthutha oludaka, indololwane, indololwane, isishishi samalahle esipuliziwe, indawo yokugaya amalahle, i-chuarse, i-opharetha ecolekile, i-opharetha umgqomo wokugqoka we-separator magnetic magnetic; 2. Gqoka ifeni ye-ceramic engazweli: zonke izinhlobo zokumelana nokushisa okuphezulu, ukumelana nokuguga, i-anti-corrosion fan impeller kanye ne-volute, okuhlanganisa ifeni eyi-centrifugal, i-axial flow fan, i-static blade, i-fan blade eshintshwayo, i-suction fan, i-powder exhauster, ifeni e-sintering, ifeni ehlukanisa impushana, ifeni yokuhlukanisa umsila we-kiln, njll. 3. Gqoka iphampu ye-ceramic eqinile ne-valve: i-ceramic lining, i-pump impeller, igobolondo, i-baffle, indololwane yepayipi, ukususwa komlotha we-pneumatic kanye ne-valve yokudlulisa igesi kanye nezinsiza ze-slurry ehlukahlukene, i-slag slurry, i-mortar, i-tailings nezinye izinhlelo zokuhamba. 4. Gqoka izigqoko ze-ceramic eziqinile: zonke izinhlobo ze-ceramic ezimelana nokugqokwa nezingashisi okuphezulu ezimelana nezinga lokushisa kanye ne-mastic zisetshenziselwa i-fan volute, i-elbow pipe, i-outlet ye-mill, ipayipi elimahhadla futhi elihle lokuhlukanisa, i-chute, i-hopper ne-valve. 5. Gqoka amathuluzi okuhlukanisa kazibuthe amelana: izingxenye zokugeleza kokugeleza zemishini ehlukahlukene yokucubungula amaminerali eyomile futhi emanzi, okuhlanganisa isigubhu sesihlukanisi kazibuthe, umsele ongezansi, i-chute, ipayipi, amaphampu odaka ahlukahlukene, i-slurry pump volute, impeller, kanye nepayipi elidlulisayo. 6. Ubuchwepheshe bokufutha phezu komhlaba: kusetshenziswa ugesi wakamuva we-inverter pulse arc we-international kanye nesibhamu sokufafaza i-arc esinesivinini esikhulu, izinto ezihlukahlukene zensimbi ezingagugi futhi ezilwa nokugqwala zifafazwa endaweni engaphansi kwensimbi ukuze kwakheke ungqimba oluvikelayo olungagugi futhi olwa nokugqwala. Inganikeza ukuvikeleka okusebenzayo kwazo zonke izinhlobo zokugqwala kwamandla amaphakathi.

I-Shandong Zhongpeng ZPC ceramics iyibhizinisi elisebenza ngokukhethekile ekukhiqizeni izitsha zobumba ezimbonini, ezisebenza kakhulu ku-R & D kanye nokukhiqizwa kwezitsha ze-silicon carbide ceramics. Singakwazi ukucubungula imikhiqizo ye-ceramic ngokwemidwebo yakho, esebenza ngokukhethekile ekukhiqizeni usayizi omkhulu, induku ye-ceramic enembayo ephezulu, ipayipi le-ceramic, indandatho ye-ceramic, ipuleti le-ceramic, i-ceramic flange, i-ceramic nozzle, kanye nezingxenye ezenziwe ngokwezifiso ezinkulu ezingagugi.

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingesinye sezixazululo ezintsha ze-silicon carbide zobumba eChina. I-ceramic yobuchwepheshe ye-SiC: Ubulukhuni be-Moh buyi-9 (ukuqina kwe-Moh entsha yi-13), enokumelana okuhle nokuguguleka nokugqwala, ukuhuzuka okuhle kakhulu – ukumelana ne-oxidation. Impilo yesevisi yomkhiqizo we-SiC iyinde izikhathi ezi-4 kuya kwezi-5 kune-alumina material engu-92%. I-MOR ye-RBSiC izikhathi ezi-5 kuye kweziyi-7 kune-SNBSC, ingasetshenziselwa izimo eziyinkimbinkimbi. Inqubo yekhotheshini iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ingeyesibili. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisele izinhliziyo zethu emphakathini.