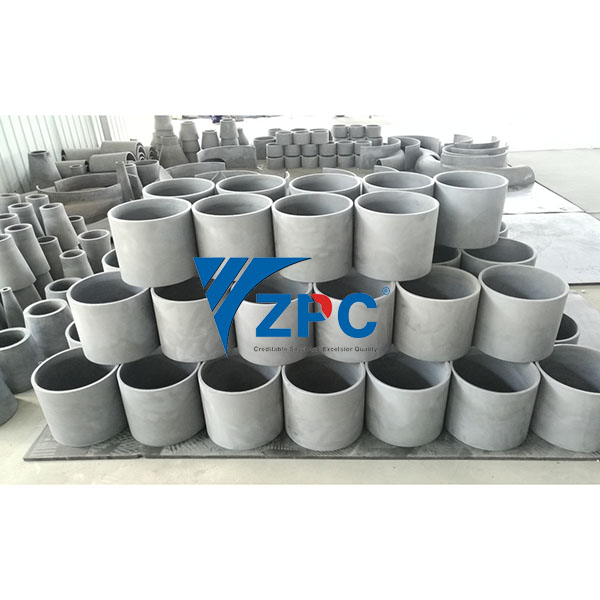

I-Wear and Abrasion resistance busher/bushing

I-silicon carbide ceramic bushing ifaka ukuqina okuphezulu, ukushisa okuphezulu kakhulu, ukumelana nokugqokwa, umthelela, ukugqwala kanye nezinga lokushisa eliphakeme, nokuphila isikhathi eside kwe-polyurethane izikhathi eziyisithupha. Isetshenziswa ikakhulukazi ekudidiyeleni, ekugxiliseni nasekuphelelweni amanzi emzimbeni kwama-granules abolayo namaholoholo ezimbonini zokugqoka i-ore, i-petroleum, ukongiwa kwamanzi, amalahle, njll.

Ipayipi le-silicon carbide ceramic wear resistantpipe likhiqizwa ngokufaka ipayipi le-ceramic elinesinki ngaphakathi kwepayipi lensimbi elinengcina (ikakhulukazi i-polyurethane). Ukuhlangana phakathi kolwelwesi lwe-ceramic kanye nepayipi lensimbi kuqinile futhi kuhle, kukwazi ukubekezelela izinga lokushisa ukusuka ku -50 ℃ kuya ku-1350 ℃. I-ceramic lining ifaka ukuqina okuphezulu, ukuguga nokuba nomthelela, ukumelana nokugqwala, indawo ebushelelezi, nokuvikela uthuli. Ubukhulu bayo buhluka kusuka ku-6 kuye ku-25 mm. Ilungele ukuhlukaniswa, ukugxilisa ingqondo, ukuphelelwa amandla kwamanzi kwezinhlayiya ezonakalisayo neziqinile. Njengamanje, isetshenziswe kabanzi ekucutshungulweni kwamaminerali, imisebenzi yokunisela, kanye nezimboni zamandla kagesi.

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingesinye sezixazululo ezintsha ze-silicon carbide zobumba eChina. I-Ceramic yobuchwepheshe ye-SiC: Ubulukhuni be-Moh buyi-9 (ukuqina kwe-Moh entsha yi-13), enokumelana okuhle nokuguguleka nokugqwala, ukuhuzuka okuhle kakhulu – ukumelana ne-oxidation. Impilo yesevisi yomkhiqizo we-SiC iyinde izikhathi ezi-4 kuya kwezi-5 kune-alumina material engu-92%. I-MOR ye-RBSiC izikhathi ezi-5 kuye kweziyi-7 kune-SNBSC, ingasetshenziselwa izimo eziyinkimbinkimbi. Inqubo yekhotheshini iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ingeyesibili. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisele izinhliziyo zethu emphakathini.