Amathayela e-Silicon Carbide Ceramic

Iklanyelwe ukumelana nezinselele zokusebenza ngokweqile,amathayili we-silicon carbideisiphenduke into esetshenziswayo yokuma ezimbonini ezidinga ukuvikelwa kokugqokwa okungayekethisi. I-microstructure yayo eyingqayizivele iletha ukusebenza okuyingqayizivele ku:

- Izindawo zokuhuzuka okukhulu eziphethe ama-coarse particulate (~ 5mm)

- Ukuhlukaniswa okunomthelela omkhulu kanye nezinhlelo zokususa amanzi

- Izokuthutha zemidiya ezonakalisayo ekucutshungulweni kwamakhorali nasezitshalweni zamakhemikhali

Kusukela kubahambisi be-steel mill slag kuya ebusweni be-mechanical seal ekukhiqizeni impahla eluhlaza,amathayili we-silicon carbideizingxenye zisebenza njengezikhali zempi ezinobunjiniyela - zivikela ngokunembile izindawo zokuguga ezibucayi kuyilapho zigcina ukuqina kohlangothi ngaphansi kwengcindezi eqhubekayo.

Njengoba kukhula isidingo samathayela e-silicon carbide, amalayini, namapayipi kuwo wonke amaketanga okucubungula amaminerali, abathengi abaqaphelayo kufanele babeke phambili lezi zilinganiso:

1. Ukwakhiwa Okuqhutshwa Ngamagugu

Inhlanganisela yethu yemvelaphi yaseJalimane ihlolwa kaningi ukuguguleka, ifinyelela amazinga okulahleka kwempahla angaphansi kuka-0.86㎝³ - ubufakazi bobuqotho be-matrix ye-silicon carbide tiles.

2. Iphrothokholi Yokuqinisekisa Ukuqina

Amathayela e-silicon carbide enza imephu ye-triaxial stress, ebonisa ubulukhuni be-Mohs obusha obungu-14.55±4.5 ngokuhlukahluka okungu-≤2% MOR kuwo wonke amaqoqo okukhiqiza.

3. Ukulawula Ukunemba Kokuminyana

I-substanding sintering idala ubungozi besakhiwo. Inqubo yethu yamathayela e-silicon carbide igcina ukuminyana okungu-3.03±0.05g/㎝³ ngokusebenzisa isibopho sokusabela esisizwa yingcindezi, sisusa izikhala ezingaphansi komhlaba.

4. Ukuphelela KweJiyomethri

▸ I-laser-verified surface flatness (<0.02mm/m²)

▸ Ukuvumelana kwerediyasi yonqenqema (0.5±0.1mm)

▸ Isitifiketi esingu-100% se-crack/esingenazimbotshana

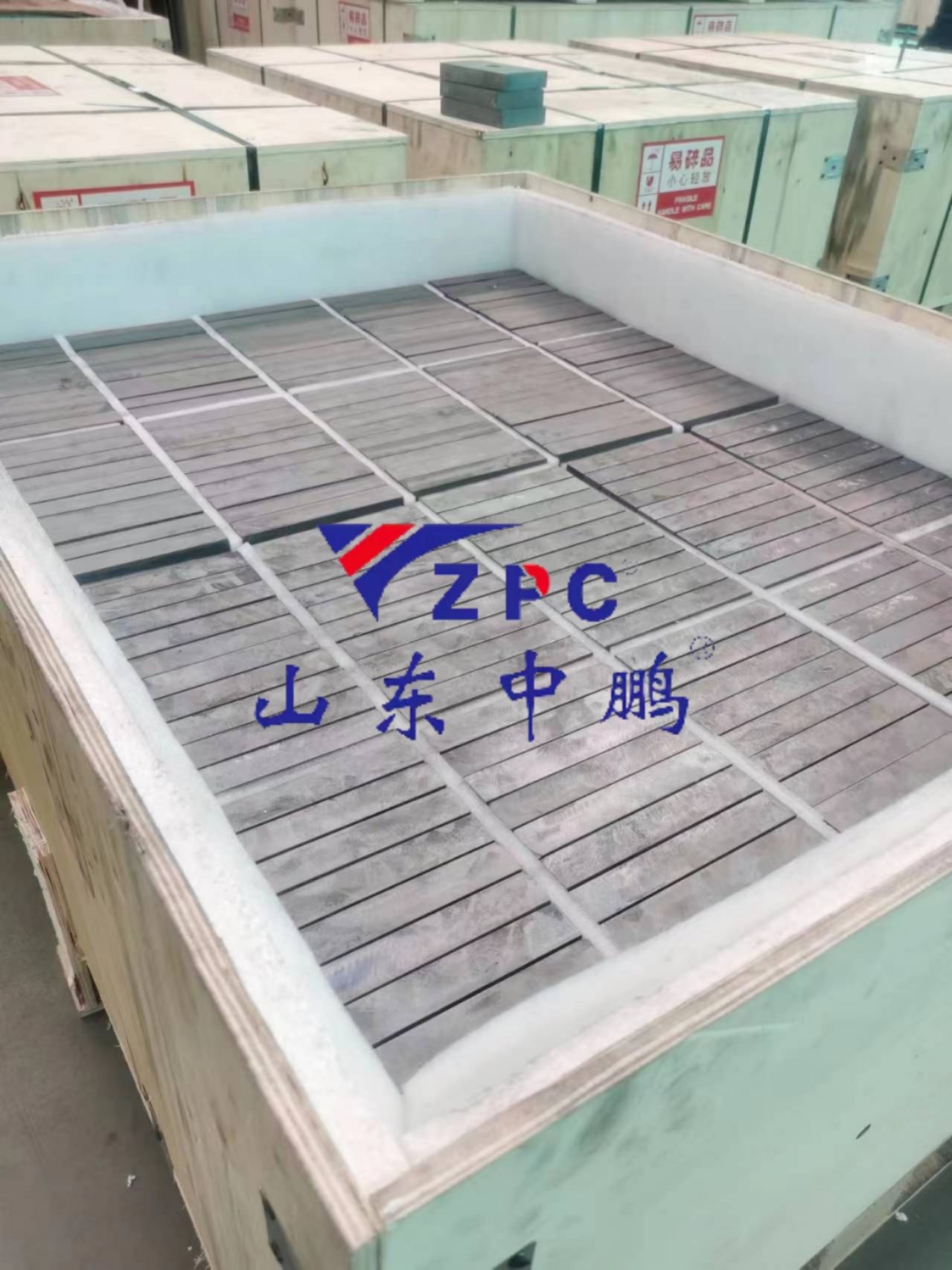

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingesinye sezixazululo ezintsha ze-silicon carbide zobumba eChina. I-ceramic yobuchwepheshe ye-SiC: Ubulukhuni be-Moh buyi-9 (ukuqina kwe-Moh entsha yi-13), enokumelana okuhle nokuguguleka nokugqwala, ukuhuzuka okuhle kakhulu – ukumelana ne-oxidation. Impilo yesevisi yomkhiqizo we-SiC iyinde izikhathi ezi-4 kuya kwezi-5 kune-alumina material engu-92%. I-MOR ye-RBSiC izikhathi ezi-5 kuye kweziyi-7 kune-SNBSC, ingasetshenziselwa izimo eziyinkimbinkimbi. Inqubo yekhotheshini iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ingeyesibili. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisele izinhliziyo zethu emphakathini.