Silikon carbide dhoobada dhoobada leh ee tuubada u adkeysaneysa xirashada iyo hydrocyclone ee dhirta korontada

Nidaamyada Tuubbooyinka dhoobada ee Silicon CarbideDib-u-cusboonaynta Kaabayaasha Dhirta Korontada

Tas-hiilaadka korontadu waxay la kulmaan caqabado shaqo oo aad u ba'an, oo leh nidaamyada tuubooyinka:

- Baaskiil kulayl joogto ah (100-650°C)

- Xawaaraha walxaha abrasive ee ka sarreeya 30 m/s

Kala duwanaanshiyaha pH ee 2-12 ee qashinka gaaska qiiqa

- Isbedbeddelka cadaadiska wareegga (0-6 MPa)

Dhuumaha macdan-dhaqameedka iyo tuubooyinka polymer-ka ayaa si joogto ah ugu guul-darraysta xaaladahan, iyagoo ka dhigaya tuubooyinka silikoon carbide (SiC) tuubooyinka xirashada adkaysiga u leh ee xalka injineernimada ee dhirta tamarta casriga ah.

Horumarka Sayniska Maadiga

Tuubooyinka dhoobada SiC waxay isku daraan sifooyin gaar ah oo muhiim u ah codsiyada qaybta tamarta:

- Vickers Hardness 28 GPa (4× ka adag carbide tungsten)

- Heerka xidhashada <0.1 mm³/N·m (ASTM G65)

Heerarka kulaylka 120 W/m·K

- Firfircoonaanta kiimikaad (waxay u adkaysataa 98% H₂SO₄ at 300°C)

Faa'iidooyinka Hawlgalka ee Nidaamyada Halis ah

1. Xakamaynta Dhuxusha & Gaadiidka Dambaska

- U adkeysan 5-7 mm/sannadii xirashada naxsiga leh 60% slurry- adag

- Ilaali <5% hoos u dhaca socodka 10,000 saacadaha shaqada

2. Naafaynta Gaaska Hargabka (FGD)

- Waxqabadka pH u adkaysta ee wareegyada slurry limestone

- Baabi'in daxalka godadka chloride-ka

3. Duulidda Ash Conveyance

- 0.08 μm qallafsanaanta dusha sare waxay yaraynaysaa ku dhegganaanshaha walxaha

- Awooda 50 tph ku qabo xagal 35°

Isbedelka Dhaqaalaha

Hawl-wadeennada dhirta ayaa ka warbixiya faa'iidooyinka la qiyaasi karo:

- 70% hoos u dhaca beddelka tuubooyinka aan la qorshayn

- 55% kharashka shaqada dayactirka oo hooseeya

- 18% hufnaanta kulaylka waxay hagaajisay wareegyada uumiga

- 40% cimriga nidaamka la dheereeyey vs. beddelka daawaha

Rakibaadda & Dabacsanaanta Hawleed

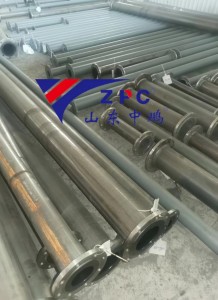

- Qaybaha 1-6 m ee moodeelka ah oo leh xiriiro fidsan

- 60% dhimista miisaanka iyo birta u dhiganta (3.2 g/cm³ cufnaanta)

- Dib loo habayn karo taageerooyinka tuubada ee jira iyo kuwa laalaada

- La jaanqaadi kara nidaamyada la socodka caqliga leh ee saadaalinta xidhashada

Hal-abuurka Mustaqbalka-Diirada

Xalalka tuubooyinka SiC ee jiilka soo socda ayaa isku dhafan:

- Porosity gradient ee dhimista cadaadiska kulaylka

- Kala duwanaanshaha wax qabad ee roobka korantada

- Kala-goysyada dhoobada-elastomer-ka isku-dhafan ee qoyaanka gariirka

- Nano-textures dusha is-nadiifinta

Laga soo bilaabo dhirta dhuxusha lagu shido ilaa tas-hiilaadka qashinka-tamarta, tuubooyinka dhoobada silikoon carbide waxay dib u qeexaan isku halaynta kaabayaasha tamarta. Isku-darkooda gaarka ah ee adkaysiga farsamada, adkeysiga kulaylka, iyo xasiloonida kiimikada waxay hubisaa in si joogto ah loo shaqeeyo xaaladaha aadka u daran - beddelka jadwalka dayactirka ee dayactirka falceliska ah ee la qorsheeyay, casriyeynta kharash-ool ah.

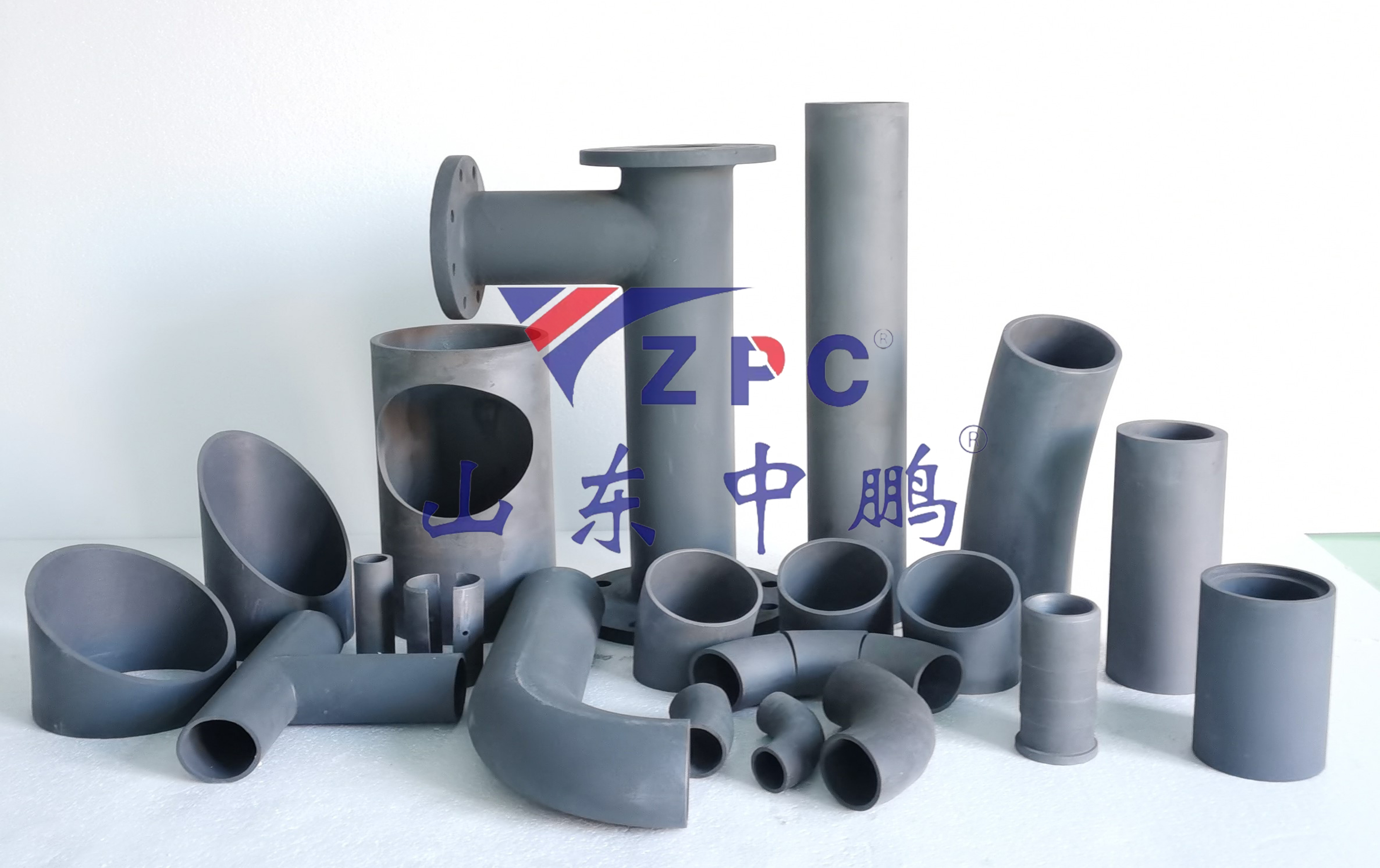

Shandong Zhongpeng Ceramics Co., Ltd waa mid ka mid ah xalalka alaabta cusub ee silikoon carbide ugu weyn ee Shiinaha. dhoobada farsamada ee SiC: Adkeeyga Moh waa 9 (Adayga cusub ee Moh waa 13), oo leh iska caabin aad u wanaagsan oo nabaadguurka iyo daxalka, nabaad-guurka aad u fiican - iska caabbinta iyo anti-oxidation. Nolosha adeegga sheyga SiC waa 4 ilaa 5 jeer in ka badan 92% walxo aluminium ah. MOR ee RBSiC waa 5 ilaa 7 jeer ka SNBSC, waxa loo isticmaali karaa qaabab aad u adag. Habka xigashada waa mid degdeg ah, gaarsiinta waa sidii balanta ahayd, tayaduna waa labaad ee midna. Had iyo jeer waxaan ku adkaysannaa inaan ka hortagno yoolalkayaga oo aan dib u soo celinno quluubtayada bulshada.