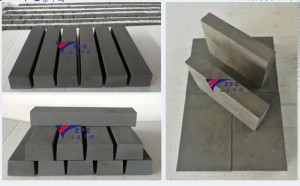

RBSC Silicon Carbide dhoobada dhoobada

RBSC Silicon Carbide dhoobada dhoobadaayaa u soo baxay sida xalka ugu horreeya ee lagula dagaallamo daalka iyo daxalka ee baahida jawiga warshadaha. Duubyada dhoobada ah ee la farsameeyay iyo dahaaradaha ayaa bixiya waxqabad aan isbarbardhig lahayn hababka maaraynta walxaha, kordhinta cimriga qalabka iyada oo la wanaajinayo hufnaanta hawleed ee hababka muhiimka ah.

Sareeyenimada Injineerinka

Qaybahayada silikoon carbide (SiC) ee saxda ah ee la soo saaray waxay ku fiican yihiin sifooyin gaar ah:

- Mohs Hardness 9.5 (13 qiyaasta la cusbooneysiiyay) ee caabbinta xirashada xad dhaafka ah

- 4–5 × adkaanta jabka weyn vs. beddelaadyada SiC ee nitride ku xidhan

- 5–7× nolol dheer oo adeeg ah marka loo eego dahaarka aluminium dhaqameed

Kiimikada ka hortagga asiidhka, alkalis, iyo dareerayaasha organic (pH 0-14)

-Xasiloonida kulaylka ilaalinta sharafta -60°C ilaa 1650°C

Xalka Ilaalinta Gaarka ah

Laga heli karo dhumucdiisuna tahay 8-45 mm, dahaarka dhoobadayadu waxay la qabsadaan shuruudaha hawlgalka ee kala duwan:

- Qaabaynta saamaynta u adkaysata ee chutes iyo hoppers

- Sagxadaha-jilicsan hoose ee hababka gudbinta

- Darajooyin nadiif ah oo sarreeya ee codsiyada cuntada/farmasiga

- Kala duwanaanshiyaha korantada ka ilaaliya meelaha qarxa

Codsiyada-Waxqabadka

1. Nidaamyada Maareynta Qalabka

- Dhuumaha qulqulka leh ee 90% nabaadguurku hoos u dhacay

- trommels macdanta oo leh 3 × wareegyo adeeg oo la fidiyey

- Duufaannada warshadda sibidhka ee ka badbaaday 50,000+ saacadaha shaqada

2. Qalabka farsamaynta

- Dhuxusha dahaarka dhuxusha iska caabbinta 120 m/s saamaynta walxaha

- Weeladaha kimikada kimikalka ah ee gacanta ku haya warbaahinta daxalaysa

- Dhuumaha dhirta birta ah ee u adkaysata dambaska duqsiga

3. Qaybaha gaarka ah

- Dahaarka daabka Rotor ee kala-soocida centrifugal

- Xidho taarikada hab-nololeedka

- Gashado u qaabaysan oo loogu talagalay joomatariyada adag

Saamaynta Dhaqaale

U gudubka dahaarka silikoon carbide waxay muujinayaan faa'iidooyin la qiyaasi karo:

- 60-80% hoos u dhaca wakhtiga aan la qorshayn

- 45% kharashka dayactirka nolosha oo hooseeya

- 30% kaydka tamarta iyada oo loo marayo socodka walxaha la hagaajiyay

- 90% dib-u-warshadaynta qaybaha duugoobay

Rakibaadda & La qabsiga

Waxaa loo naqshadeeyay is dhexgalka aan kala go 'lahayn:

- Nidaamyada foornada modulka leh oo leh naqshado isku xiran

- Epoxy-xoog-sare ama hagaajin farsamo

- Adeegyada farsamaynta iyo dib-u-habaynta goobta

- Waafaqid labbiska wakhtiga-dhabta ah

Hal-abuurka mustaqbalka-diyaarsan

Jiilka soo socda ee dahaarka carbide silicon waxaa ka mid ah:

- Qaabdhismeedka cufnaanta gradient ee nuugista saamaynta

- Daawaynta dusha is-saliimaysa

- Raadinta xidhashada karti u leh RFID

- Nidaamyada isku-dhafka dhoobada-birta ah ee isku-dhafan

Laga soo bilaabo hawlgallada macdanta ilaa dhirta warshadaynta kiimikada, dahaarka dhoobada silikoon carbide waxay u taagan yihiin heerka cusub ee ilaalinta xidhashada warshadaha. Isku-darkooda gaarka ah ee u adkaysiga farsamada, xasiloonida kiimikada, iyo adkaysiga kulaylka ayaa beddela waxqabadka qalabka - yaraynta kharashyada meertada nolosha iyada oo kor loo qaadayo isku halaynta wax soo saarka ee goobaha shaqada ee ugu xun adduunka.

Shandong Zhongpeng Ceramics Co., Ltd waa mid ka mid ah xalalka alaabta cusub ee silikoon carbide ugu weyn ee Shiinaha. dhoobada farsamada ee SiC: Adkeeyga Moh waa 9 (Adayga cusub ee Moh waa 13), oo leh iska caabin aad u wanaagsan oo nabaadguurka iyo daxalka, nabaad-guurka aad u fiican - iska caabbinta iyo anti-oxidation. Nolosha adeegga sheyga SiC waa 4 ilaa 5 jeer in ka badan 92% walxo aluminium ah. MOR ee RBSiC waa 5 ilaa 7 jeer ka SNBSC, waxa loo isticmaali karaa qaabab aad u adag. Habka xigashada waa mid degdeg ah, gaarsiinta waa sidii balanta ahayd, tayaduna waa labaad ee midna. Had iyo jeer waxaan ku adkaysannaa inaan ka hortagno yoolalkayaga oo aan dib u soo celinno quluubtayada bulshada.