pfeka zvisingagadziriswi nesilicon carbide ceramic tiles

![]()

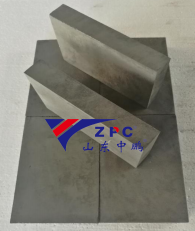

Reaction bonded silicon carbide (SiSiC kana RBSIC) chinhu chakanakira kupfeka chisingachinji, chinova.

kunyanya yakakodzera kune yakasimba abrasive, coarse particles, classification, concentration, dehydration uye

mamwe maoparesheni. Inoshandiswa zvakanyanya muindasitiri yemigodhi, indasitiri yesimbi, coral processing indasitiri, kemikari

indasitiri, indasitiri yekugadzira zvinhu, mechini yekuisa chisimbiso, pamusoro pejecha kurapa uye kuratidza nezvimwe.

Nekuda kwekuomarara kwakanyanya uye abrasive kuramba, inogona kunyatso chengetedza chikamu chinodiwa kupfeka

kudzivirira, kuitira kuti uwedzere hupenyu hwebasa remidziyo.

Nzira yekuziva uye kuwana emhando yepamusoro silicon carbide kupfeka-resistant mahwendefa, mataira, liner?

Silicon carbide kupfeka-resistant tiles, liner, pombi zviri kuwedzera uye zvakanyanya kushandiswa muindasitiri yemigodhi.

Aya mapoinzi anotevera ndeekutarisa kwako:

1. Formula uye maitiro:

Kune akawanda maSiC magadzirirwo pamusika. Isu tinoshandisa echokwadi maumbirwo echiGerman. Mune yepamusoro-level laboratory bvunzo, chigadzirwa chedu Erosion ㎝³ kurasikirwa kunogona kusvika 0.85 ± 0.01;

2. Kuoma:

SiC mataira anogadzirwa muZPC: nyowani Mohs kuomarara: 14.55 ± 4.5 (MOR, psi)

3. Density:

ZPC SiC tile's density range inosvika 3.03+0.05.

4. Saizi uye Surface:

SiC mataira anogadzirwa muZPC asina kutsemuka uye pores, ane nzvimbo yakati sandara uye mipendero isina kusimba nemakona.

5. Internal zvinhu:

Silicon carbide kupfeka-resistant liners / matiles ane yakanaka uye yakafanana mukati nekunze zvinhu.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Zvinodiwa:

| Item | Unit | Data |

| Tembiricha yekushandisa | ℃ | 1380 ℃ |

| Density | G/cm3 | >3.02 |

| Open porosity | % | <0.1 |

| Kupeta simba -A | Mpa | 250 (20℃) |

| Kupeta simba -B | MPa | 280 (1200℃) |

| Modulus ye elasticity-A | GPA | 330(20℃) |

| Modulus ye elasticity -B | GPA | 300 ( 1200 ℃ ) |

| Thermal conductivity | W/mk | 45 (1200℃) |

| Coefficient yekuwedzera kwekushisa | K-1 × 10-6 | 4.5 |

| Kuoma musoro | / | 13 |

| Acid-proof alkaline | / | zvakanakisa |

■Inowanikwa Shape uye saizi:

Ukobvu: kubva 6mm kusvika 25mm

Regular Shape: SISIC plate, SISIC Pipe, SiSiC Three Links, SISIC Elbow, SISIC Cone Cyclone.

Remark: Mamwe saizi uye chimiro zviripo pane zvikumbiro.

■Kurongedza:

Mubhokisi bhokisi, rakarongedzwa mufumigated yemapuranga pallet ine huremu hwemambure 20-24MT/20′FCL.

■Mabhenefiti akakosha:

1. Yakanakisa kupfeka kuramba, kukanganisa kupikisa uye kusagadzikana kwemarara;

2. Yakanakisa flatness uye yakanakisa tembiricha kuramba kusvika 1350 ℃

3. Kuiswa nyore;

4. Hupenyu hwesevhisi hurefu (hunopfuura ka7 kupfuura hwealuminium ceramic uye ka10 kupfuura iyo

polyurethane

Patani yekona inokanganisa abrasion Yakaderera kona inotsvedza

Kana kuyerera kwechinhu chinokwesha kuchirova nzvimbo yakasakara pakona isina kudzika kana kupfuura yakafambirana nayo, mhando yekupfeka inoitika mukukwesha inodaidzwa kuti sliding abrasion.

Yepamberi silicon carbide ceramics inopa kupfeka kuramba uye corrosion kuramba mataira e ceramic uye lining. Izvi zvigadzirwa zvakaratidzwa kupfeka kwemidziyo mukufambisa, kugadzirisa, uye kuchengetedza maitiro. Mataira edu anogona kugadzirwa nehukobvu kubva pa8 kusvika 45mm. zvakakosha kuve nechokwadi chekuti unogona kuwana zvigadzirwa zvinodiwa. SiSiC: Kuoma kweMoh ndeye 9.5 (Kuoma kweMoh kutsva i13), ine kupesana kwakanaka kwekukurwa nekuora, kuparara kwakanyanya - kuramba uye anti-oxidation. Iine simba rakapetwa kana kana kashanu pane nitride yakasungirirwa silicon carbide. Hupenyu hwesevhisi ndeye 5 kusvika 7 nguva yakareba kupfuura alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Pfeka inopokana neceramic lining inoitisa kuvandudza mashandiro ekugadzira, kushanda zvakanaka, kudzikiswa kwemitengo yekuchengetedza uye kuwedzera purofiti.

Precision ceramics vane ruzivo rwezvinhu, hunyanzvi hwekushandisa uye hunyanzvi hweinjiniya. Izvi zvinogona kunyatso kuve nechokwadi chekuti mhinduro dzakanakisa dzinopihwa kune vatengi vedu. Silicon carbide ceramic mataira uye lining anowanzo shandiswa mumashandisirwo akadai semadutu, machubhu, chute, hoppers, mapaipi, mabhandi ekutakurisa uye masisitimu ekugadzira. Muhurongwa, pane zvinhu zvinofamba zvinotsvedza pamusoro. Kana chinhu chacho chichitsvedza pachinhu, chinopfeka zvishoma nezvishoma kusvikira pasina chinosara. Munzvimbo dzakapfeka zvakanyanya, izvi zvinogona kuitika kazhinji uye zvichikonzera matambudziko mazhinji anodhura. Chimiro chikuru chinochengetwa nekushandisa chinhu chakanyanya kuoma, senge silicon carbide ceramics uye alumina ceramics sechibairo chirairo. Panguva imwecheteyo, silicon carbide ceramics inogona kutsungirira kupera kwenguva refu isati yada kutsiviwa, iyo silicon carbide ceramic sevhisi hupenyu hwakareba kashanu kusvika kanomwe pane alumina zvinhu.

Pfeka Resistant Silicon Carbide Ceramic Tiles & Lining Properties:

Kusagadzikana kwemakemikari

Magetsi anodzivirira

Kukukurwa kweMechanical & Abrasion inoshingirira

Inotsiviwa

Zvakanakira zveCeramic Wear Resistant Tiles & Linings:

Inogona kushandiswa uko kushivirira kwakasimba kana matete linings anodiwa

Inogona kushandiswa kumutsiridza nzvimbo dziripo dzekupfeka

Inogona kushandiswa nenzira dzakawanda dzekunamatira senge welding uye zvinonamira

Tsika yakagadzirirwa kune chaiyo maapplication

Kunyanya kusagadzikana nekuora

Chigadziriso chekudzikisa kupfeka chisina kuremerwa

Inodzivirira zvikamu zvinofamba zviri pasi penzvimbo dzakapfeka zvakanyanya

Yakanyanya kubuda & inokunda kupfeka kugadzirisa mhinduro

Tembiricha yekushandiswa kwepamusoro-soro inosvika 1380°C

1, Simbi nesimbi chirimwa: 1, sintering muchina dhiramu musanganiswa lining 2, dhiramu yakaputirwa ceramic rabha 3, fan impeller 4, disc feeder, yakaoma zvinhu dhiri 5, coke hopper, converter bhini, coke bhini, dutu guru muunganidzi.

2, Chigayo chemagetsi: 1. Bhora chigayo chinobuda, chigayo chepakati, chepakati chekumhanya chigayo, pombi yehupfu mugokora, dutu redutu rinounganidza, silo, hopper 2, marasha hopper, coarse uye yakatsetseka poda separator, marasha chigayo chinoburitsa, marasha anotakura hopper 3, marasha hopper yebhiriji kubata, pakati pemhangura yekubuda kwecoal uye hopper. yehupfu hwakakasharara uye hwakatsetseka separator, volute yepoda exhauster 4 Mhando dzakasiyana-siyana dzakananga ikozvino, dzinotenderera dzakasimba uye dzakanyungudutsa tembiricha dzinopisa dzinopisa dzinopisa dzemaboiler anobatidzwa nemarasha; mapaipi nemagokora akakwirira-kupfeka-anodzivirira ceramic composite, zvinopisa zveceramic, mafeni e ceramic, ma impeller e ceramic, mavharuvhu e ceramic, nezvimwewo; zvikamu zvakasiyana-siyana zvinodzivirira kupfeka zvakadai semabhora ekukuya, mawoko emakumbo, madhisiki ekukuya, mataira edhisiki, zvindori zvekukuya, mabhora emhuno nezvimwe zvikamu zvisingapfekeki zvezvigayo zvemarasha zviri pakati nepakati; mapaipi, kupfeka-inodzivirira damper uye mafeni eakasiyana maratidziro ekupuruzira uye ekubvisa madota masisitimu; mabhora Ese marudzi eguyo ane (kana kwete) bolt lining tile, lining plate, spiral pipe, gear ring, low chromium alloy simbi bhora, nezvimwewo; vhiri rinorovera, ndiro inorovera, chirauro chevarindi, nhumbi dzokurwa nadzo, chinoparadzanisa, tembiricha yefurnace flue gasi pombi, nezvimwewo zvechigayo chemarasha; zvishongedzo zvinodiwa pamhando dzakasiyana dzekupwanya michina.

3, Pepa chigayo: 1. Pulverized marasha pombi

Zvigadzirwa zvikuru uye masevhisi: 1. Maindasitiri anopfeka-anodzivirira Ceramic pombi: marudzi ese ekupfeka-anodzivirira uye yakakwirira-tembiricha inodzivirira karamic yakamisikidzwa nemarasha akapwanyika, tailings, slag slurry, slurry yekufambisa pombi, gokora, gokora, pulverized marasha anopisa, marasha chigayo chinobuda, churu chehupfu, poda yekuchengetera, poda yehupfu uye pombi yakanaka. kupfekedza chirongo chemugodhi magnetic separator; 2. Pfeka inodzivirira ceramic fan: marudzi ese emhando yepamusoro inodzivirira, inomira-inomira, anti-corrosion fan impeller uye volute, kusanganisira centrifugal fan, axial flow fan, static blade, inofambiswa blade inochinjika fan impeller, suction fan, poda exhauster, sintering feni, poda yekuparadzanisa fan, guruva musoro feni, etc. 3. Pfeka inodzivirira ceramic lining pombi uye vharafu: ceramic lining, pombi impeller, goko, baffle, pombi gokora, pneumatic ash kubviswa uye gasi kutapurirana vharafu uye zvishongedzo zvakasiyana-siyana slurry, slag slurry, dhaka, tailings uye mamwe masisitimu ekufambisa. 4. Pfeka machira eceramic anoramba: marudzi ese ekupfeka-anodzivirira uye akakwirira-kupisa anodzivirira ceramic coatings uye mastic anoshandiswa kune fan volute, gokora pombi, chigayo chinobuda, yakaoma uye yakanaka separator pombi, chute, hopper uye valve. 5. Pfeka magineti anodzivirira magineti ekuparadzanisa michina: kuyerera kwezvikamu zvezvakasiyana-siyana zvakaoma uye zvakanyorova zvicherwa zvekugadzira zvicherwa, zvinosanganisira magineti separator dhiramu, pasi groove, chute, pombi, mapombi akasiyana-siyana ematope, slurry pump volute, impeller, uye pombi inotakura. 6. Kupfapfaidza tekinoroji: uchishandisa ichangoburwa yepasirese inverter pulse arc magetsi uye yakakwirira-speed arc spraying pfuti, zvakasiyana-siyana kusapfeka-resistant uye anti-corrosion metal zvinhu zvakapfapfaidzwa pamusoro pesimbi substrate pamusoro kuti iite kupfeka-kusagadzikana uye anti-corrosion inodzivirira layer. Inogona kupa dziviriro inoshanda kune ese marudzi epakati simba kupfeka ngura.

Shandong Zhongpeng ZPC ceramics ibhizinesi rinonyanya kugadzirwa kwemaindasitiri eceramics, anonyanya kuita muR & D uye kugadzirwa kwesilicon carbide ceramics. Isu tinokwanisa kugadzira zvigadzirwa zveceramic zvinoenderana nedhirowa yako, inyanzvi mukugadzirwa kwehukuru hwakakura, yakakwira chaiyo tsvimbo yedomi, pombi yedomi, mhete ye ceramic, ndiro ye ceramic, ceramic flange, ceramic nozzle, uye yakagadziridzwa hombe saizi isingapfekere zvikamu.

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yeyakakura silicon carbide ceramic zvinhu zvitsva zvinogadziriswa muChina. SiC technical ceramic: Kuomarara kweMoh ndeye 9 (Kuoma kweMoh kutsva ndeye 13), nekupokana kwakanyanya kukukurwa nekuora, kunyura kwakanakisa - kuramba uye anti-oxidation. Hupenyu hwesevhisi yechigadzirwa cheSiC hwakareba 4 kusvika kashanu kupfuura 92% alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Iyo quotation process inokurumidza, kuendesa kwakavimbiswa uye mhando ndeyechipiri kune imwe. Isu tinogara tichishingirira kupikisa zvinangwa zvedu uye nekudzorera moyo yedu kunharaunda.