Pfeka zvisingaite silicon carbide ceramic pombi

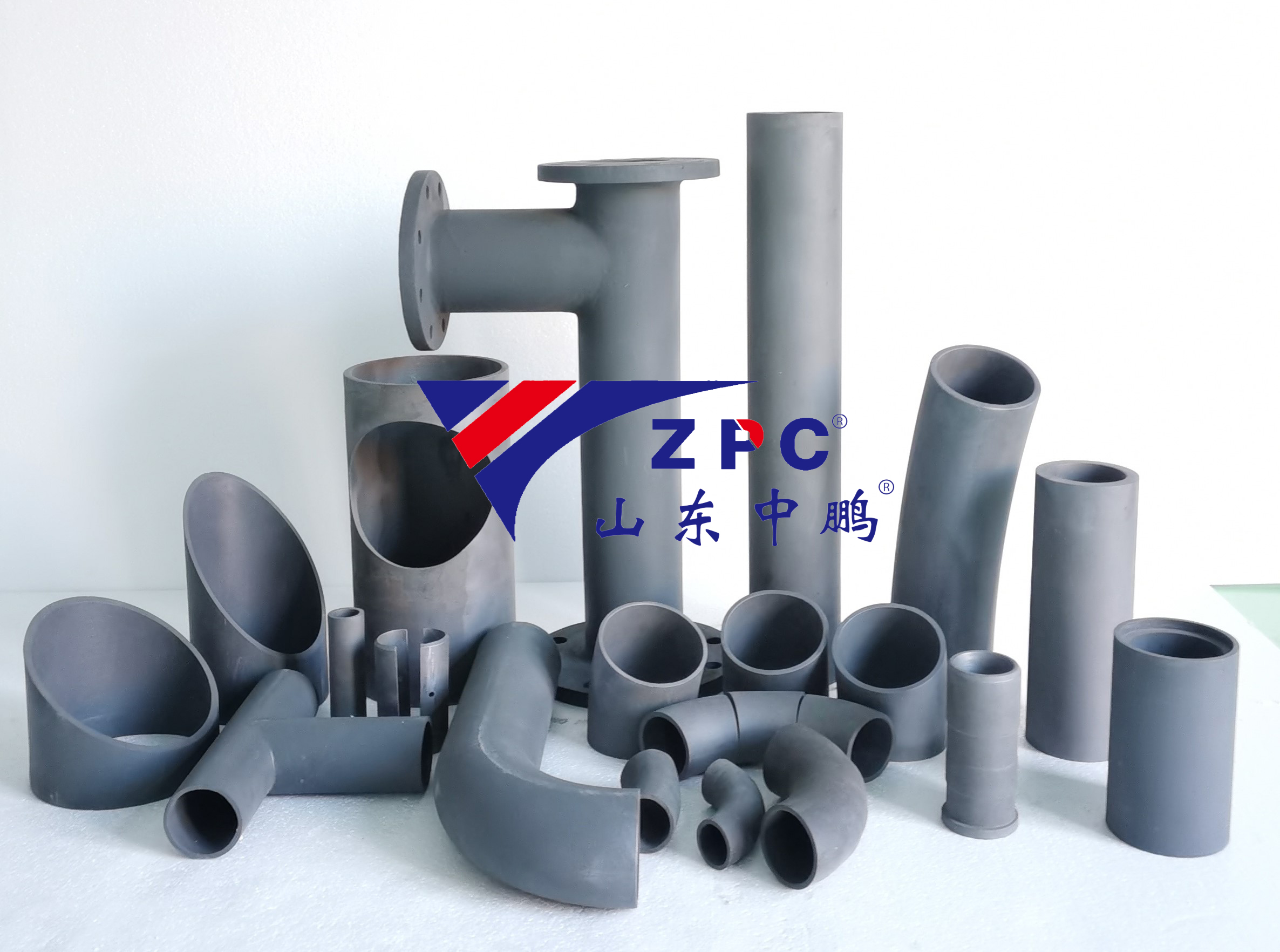

Silicon Carbide ceramic mitsetse mapaipi:

![]() Reaction bonded silicon carbide (SiSiC kana RBSIC) yakanakira kupfeka inodzivirira zvinhu, iyo inonyanya kukodzera kune yakasimba abrasive, coarse particles, classification, concentration, dehydration uye mamwe maoperation.

Reaction bonded silicon carbide (SiSiC kana RBSIC) yakanakira kupfeka inodzivirira zvinhu, iyo inonyanya kukodzera kune yakasimba abrasive, coarse particles, classification, concentration, dehydration uye mamwe maoperation.

Inoshandiswa zvakanyanya muindasitiri yemigodhi, indasitiri yesimbi, coral processing indasitiri, kemikari

industry, raw material-making industry, mechanical sealing, surface sandblasted treatment and reflector etc. Iyo yakanakisa kuoma uye abrasive kuramba, inogona zvinobudirira kudzivirira chikamu chinoda kupfeka kudzivirira, kuitira kuti uwedzere hupenyu hwebasa remidziyo.

■Zvinodiwa:

| Item | Unit | Data |

| Tembiricha yekushandisa | ℃ | 1380 ℃ |

| Density | G/cm3 | >3.02 |

| Open porosity | % | <0.1 |

| Kupeta simba -A | Mpa | 250 (20℃) |

| Kupeta simba -B | MPa | 280 (1200℃) |

| Modulus ye elasticity-A | GPa | 330(20℃) |

| Modulus ye elasticity -B | GPa | 300 ( 1200 ℃ ) |

| Thermal conductivity | W/mk | 45 (1200℃) |

| Coefficient yekuwedzera kwekushisa | K-1 × 10-6 | 4.5 |

| Kuoma musoro | / | 13 |

| Acid-proof alkaline | / | zvakanakisa |

■Inowanikwa Shape uye saizi:

Ukobvu: kubva 6mm kusvika 25mm

Regular Shape: SISIC plate, SISIC Pipe, SiSiC Three Links, SISIC Elbow, SISIC Cone Cyclone.

Remark: Mamwe saizi uye chimiro zviripo pane zvikumbiro.

■Kurongedza:

Mubhokisi bhokisi, rakarongedzwa mufumigated yemapuranga pallet ine huremu hwemambure 20-24MT/20′FCL.

■Mabhenefiti akakosha:

1. Yakanakisa kupfeka kuramba, kukanganisa kupikisa uye kusagadzikana kwemarara;

2. Yakanakisa flatness uye yakanakisa tembiricha kuramba kusvika 1350 ℃

3. Kuiswa nyore;

4. Hupenyu hwesevhisi hurefu (hunopfuura ka7 kupfuura hwealuminium ceramic uye ka10 kupfuura iyo

polyurethane

Dhizaini yepombi ine ceramic lining:

Ceramic Material: RBSiC, SiSiC, SSiC, 99.5% Alumina, 99% Alumina, 95% alumina

- Mapaipi, kugadzirwa kwese;

- Ndiro, ndiro inopenya

- Matairi, matanda e ceramic.

Patani yekona inokanganisa abrasion Yakaderera kona inotsvedza

Kana kuyerera kwechinhu chinokwesha kuchirova nzvimbo yakasakara pakona isina kudzika kana kupfuura yakafambirana nayo, mhando yekupfeka inoitika mukukwesha inodaidzwa kuti sliding abrasion.

Yepamberi silicon carbide ceramics inopa kupfeka kuramba uye corrosion kuramba mataira e ceramic uye lining. Izvi zvigadzirwa zvakaratidzwa kupfeka kwemidziyo mukufambisa, kugadzirisa, uye kuchengetedza maitiro. Mataira edu anogona kugadzirwa nehukobvu kubva pa8 kusvika 45mm. zvakakosha kuve nechokwadi chekuti unogona kuwana zvigadzirwa zvinodiwa. SiSiC: Kuoma kweMoh ndeye 9.5 (Kuoma kweMoh kutsva i13), ine kupesana kwakanaka kwekukurwa nekuora, kuparara kwakanyanya - kuramba uye anti-oxidation. Iine simba rakapetwa kana kana kashanu pane nitride yakasungirirwa silicon carbide. Hupenyu hwesevhisi ndeye 5 kusvika 7 nguva yakareba kupfuura alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Pfeka inopokana neceramic lining inoitisa kuvandudza mashandiro ekugadzira, kushanda zvakanaka, kudzikiswa kwemitengo yekuchengetedza uye kuwedzera purofiti.

Precision ceramics vane ruzivo rwezvinhu, hunyanzvi hwekushandisa uye hunyanzvi hweinjiniya. Izvi zvinogona kunyatso kuve nechokwadi chekuti mhinduro dzakanakisa dzinopihwa kune vatengi vedu. Silicon carbide ceramic mataira uye lining anowanzo shandiswa mumashandisirwo akadai semadutu, machubhu, chute, hoppers, mapaipi, mabhandi ekutakurisa uye masisitimu ekugadzira. Muhurongwa, pane zvinhu zvinofamba zvinotsvedza pamusoro. Kana chinhu chacho chichitsvedza pachinhu, chinopfeka zvishoma nezvishoma kusvikira pasina chinosara. Munzvimbo dzakapfeka zvakanyanya, izvi zvinogona kuitika kazhinji uye zvichikonzera matambudziko mazhinji anodhura. Chimiro chikuru chinochengetwa nekushandisa chinhu chakanyanya kuoma, senge silicon carbide ceramics uye alumina ceramics sechibairo chirairo. Panguva imwecheteyo, silicon carbide ceramics inogona kutsungirira kupera kwenguva refu isati yada kutsiviwa, iyo silicon carbide ceramic sevhisi hupenyu hwakareba kashanu kusvika kanomwe pane alumina zvinhu.

Pfeka Resistant Silicon Carbide Ceramic Tiles & Lining Properties:

Kusagadzikana kwemakemikari

Magetsi anodzivirira

Kukukurwa kweMechanical & Abrasion inoshingirira

Inotsiviwa

Zvakanakira zveCeramic Wear Resistant Tiles & Linings:

Inogona kushandiswa uko kushivirira kwakaomarara kana matete linings anodiwa

Inogona kushandiswa kumutsiridza nzvimbo dziripo dzekupfeka

Inogona kushandiswa nenzira dzakawanda dzekunamatira senge welding uye zvinonamira

Tsika yakagadzirirwa kune chaiyo maapplication

Kunyanya kusagadzikana nekuora

Chigadziriso chekudzikisa kupfeka chisina kuremerwa

Inodzivirira zvikamu zvinofamba zviri pasi penzvimbo dzakapfeka zvakanyanya

Yakanyanya kubuda & inokunda kupfeka kugadzirisa mhinduro

Tembiricha yekushandiswa kwepamusoro-soro inosvika 1380°C

1. Steel industry

Conveying system: bhakiti vhiri Bai, disc, hopper Du, silo, bhandi rekutakura apron, trolley tee, kugamuchira hopper

Batching system: kusanganisa silo, yekutanga Dao kusanganisa silinda, yechipiri kusanganisa silinda, kusanganisa disc, kusanganisa dhiramu, scraper, pelletizing ndiro.

Sintering system: Beneficiation hopper pasi pekuzunguza skrini, chute yekutakura zvinhu, dutu redutu rinounganidza uye pombi, fan impeller.

2. Indasitiri yesimende:

Limestone kupwanya system uye mbishi uye mafuta pre homogenization system: chute, hopper, bhandi chigubhu.

Raw mill system: separator gwara vane, separator cone, vertical mill kune cyclone chubhu, dutu, chigayo chemafuta (simbi bhora chigayo), imba yekuparadzanisa, cone yemukati, pombi yemarasha yakapwanyika.

Chigayo chemafuta (simbi bhora chigayo): imba yekuparadzanisa, cone yemukati, pombi yemarasha yakapwanyika, pombi inodzosera poda

3. Port industry

Yakagadziriswa hopper yekutandarira, hopper yemuchina webhaketi vhiri, yakagadziriswa hopper yebhandi conveyor yekufambisa chiteshi, hopper yekuburitsa chikepe

4. Indasitiri yekunyungudutsa

Conveying system: musoro chute, silo (yepakati bhini, bhini remuswe), vibrating screen trough, coke hopper, metering hopper

Batching system: batching hopper, yekutanga (yechipiri) musanganisi

Roasting system: single bin pombi, calcine chubhu, batching hopper, ash hopper, yepakati bhini hopper

5. Indasitiri yemakemikari:

Kufambisa sisitimu: hopper, silo

Dust yekubvisa system: guruva rekubvisa pombi, gokora, fan casing uye impeller, dutu

6. Indasitiri yemarasha:

Marasha ekubata system: chute, hopper, silo

Coal washing system: pressure cyclone, non pressure three product heavy medium cyclone, non pressure four product heavy medium cyclone, concentration cyclone group

Conveying system: pombi, gokora, pombi, hopper, silo, chiteshi chekugovera

7. Indasitiri yezvicherwa:

Conveying system: hopper silo

Refractory Ceramics

Pfeka Inodzivirira

Mine Classification Cyclone

Musanganiswa PU

Compound Polyurethane

Sisic Lined Simbi

Refractory ceramic

SSIC inodzivirira casing

RBSIC inodzivirira sleeve

Silicon Carbide Burner Nozzle

Silicon Carbide Nozzle Tube

E-Cigarette Accessories

Refractory Ceramics

Kiln Furniture

High Temperature Resistance

Reaction Bonded Silicon Carbide

Midziyo yekudzivirira yemauto

Anti-puncture

Abrasion Protection

Resistant

Simbi isina ngura

Yakagadzirwa muChina Pfeka-Resistant Ceramics Compound Polyurethane

China Compound PU

China Compound Polyurethane

Alumina Ceramic

Tube

1650c High Temperature Sic Tube

Yakagadzirwa muChina Wear-Resistant Ceramic Composite PU

High Presicion Silicon Carbide Ceramics

High Purity Silicon Carbide Ring

Irregular Silicon Carbide Ceramic Zvikamu

Ceramic Zvikamu

Silicon Carbide Ceramic Fittings

Ceramic Accessories

Yakagadzirwa muChina Pfeka-Inodzivirira Ceramic Composite Sisic Lined Simbi

Ceramic Chikamu

Yakagadzirwa muChina Wholesale Certified Wear-Resistant Ceramic Composite Polyurethane

High Hardness

92% Alumina

Yakagadzirwa muChina Industrial Wear-Resistant Ceramic Composite Polyurethane

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yeyakakura silicon carbide ceramic zvinhu zvitsva mhinduro muChina. SiC technical ceramic: Kuomarara kweMoh ndeye 9 (Kuoma kweMoh kutsva ndeye 13), nekupokana kwakanyanya kukukurwa nekuora, kunyura kwakanakisa - kuramba uye anti-oxidation. Hupenyu hwesevhisi yechigadzirwa cheSiC hwakareba 4 kusvika kashanu kupfuura 92% alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Iyo quotation process inokurumidza, kuendesa kwakavimbiswa uye mhando ndeyechipiri kune imwe. Isu tinogara tichishingirira kupikisa zvinangwa zvedu uye nekudzorera moyo yedu kunharaunda.