SiC Crucibles uye Saggers inogadzira / fekitori - SiC Sagger yePowder Sintering

SiC Sagger yePowder Sintering

RBSIC/SISIC crucible ndiro yakadzika yemidziyo yeceramic. Nekuda kwekuita kwayo kurinani pane glassware pakupisa kupisa, Inonyatso shandiswa kana maomarara achipiswa nemoto.

Sagger inogadzirwa nedhaka refractory yeakasiyana maratidziro edhaka, yakabikwa nekupisa kwakanyanya. Ndiyo imwe yeakakosha honi fenicha yekupisa porcelain. Mhando dzese dzema porcelain dzinofanirwa kuiswa mumasaga kutanga uyezve muchoto chekugocha.

ZVINOTAURWA:

| Index | RSiC | NSiC | RBSiC | SiC |

| Kuwanda kwehuwandu (g/cm3) | 2.65-2.75 | 2.75-2.85 | ≥3.02 | 2.8 |

| SiC(%) | ≥99 | ≥75 | 83.66 | 90 |

| Si3N4(%) | 0 | ≥23 | 0 | 0 |

| Si(%) | 0 | 0 | 15.65 | 9 |

| Porosity(%) | 15-18 | 10-12 | 0.1 | 7-8 |

| Kubhenda simba (MPa) | 80-100(20℃) | 160-180(20℃) | 250(20℃) | 500(20℃) |

| Kubhenda simba (MPa) | 90-110(1200℃) | 170-180(1200℃) | 280(1200℃) | 550(1200℃) |

| Kubhenda simba (MPa) | 90-120(1350℃) | 170-190(1350℃) | - | - |

| Modulus ye elasticity (GPa) | 300(20℃) | 580(20℃) | 330(20℃) | 200 |

| Modulus ye elasticity (GPa) | - | - | 300(1200℃) | - |

| Thermal conductivity(wm-1.k-1) | 36.6(1200℃) | 19.6(1200℃) | 45(1200℃) | 13.5-14.5(1000℃) |

| Coefficient yekuwedzera kwekupisa (K-1 × 10-6) | 4.69 | 4.7 | 4.5 | 3 |

| Kuoma musoro | - | - | 13 | - |

| Max kushanda tembiricha (℃) | 1620 (oxid) | 1450 | 1380 | 1300 |

Fekitari:

Nezvedu:

Isu tiri kambani inoshanda mukugadzirwa kweRBSIC/SIC Silicon Infiltrated Silicon Carbide Zvigadzirwa.

- Professional Kugadzira Maitiro

- Yakatorwa Yemhando yepamusoro Zvishandiso

- Yakazara Yekugadzira Managing System

CATALOGUE:

Zvakanakira:

- Simba repamusoro uye kuoma kwakanyanya

-Kupikisa kwekushisa kwepamusoro uye zvakanakisa kupisa kwekutya kwekudzivirira

- Yakanakisa kutakura kugona

- Kuramba kupisa kwakanyanya uye kutonhora.

- High tembiricha zvinokambaira kuramba

- Corrosion kuramba uye Oxidation kuramba

- Acid uye alkali kuramba

- Pfeka kuramba uye yakanaka yekupisa conductivity

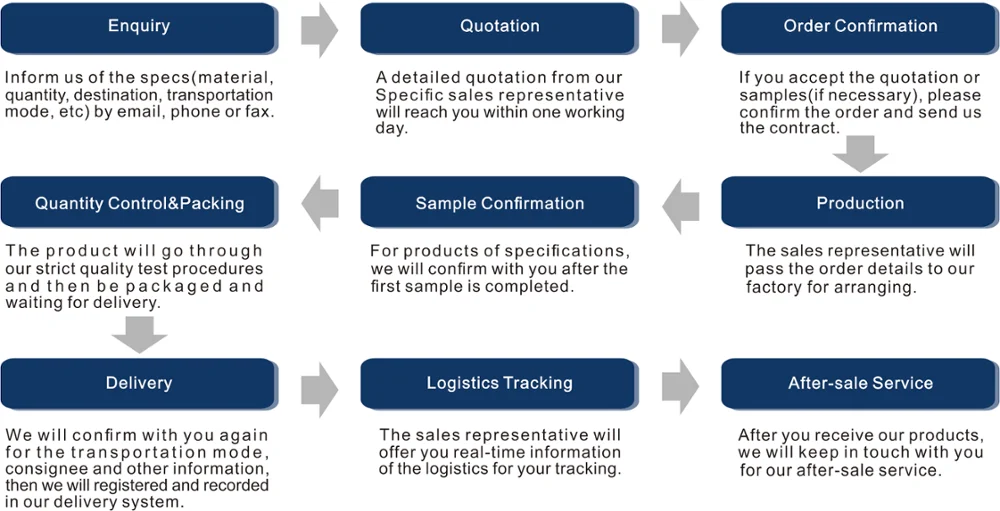

ORDER PROCESS:

KUGADZIRA PROCESS:

Iyo silicon carbide ceramics crucibles uye saggers inogona kushandiswa kwakasiyana siyana upfu, kunyungudutsa simbi, nezvimwewo muminda yesimbi, indasitiri yemakemikari, girazi nezvimwe zvakadaro. Shandong Zhongpeng yakazvipira kutsvagisa nekusimudzira, kugadzira uye kutengesa kwepamusoro-inoshanda silicon carbide zvigadzirwa, izvo zvakakosha zvigadzirwa ndezvekuita sintered silicon carbide ceramic matanda, roller mabara, moto nozzles, inotonhora mhepo ducts, mashedhi, enamel, enamel, thermocouple dziviriro Tube, kupisa kupisa chubhu, inopenya chubhu yemukati chubhu, inopenya, inopenya tubhu yemukati, inopenya choto chubhu, jecha rinoputika nozzle, bushing, chisimbiso uye dzakasiyana tembiricha yakakwira, kupfeka uye kusakara kunopesana nesilicon carbide ceramic shaped Piece, nezvimwewo, reaction sintered silicon carbide ceramic zvigadzirwa zvine simba rakawanda, kuomarara kwepamusoro, kupfeka kusagadzikana, kupisa kwekushisa kwepamusoro, corrosion resistance, oxidation resistance, thermal shock resistance uye kukurumidza kupisa kwekushisa, kukurumidza kusimba kwekushisa uye kukurumidza kupikisa kupisa. mauto, aerospace, simba renyukireya, liquid crystal uye simbi, makemikari, michina, motokari, bepa, mushonga uye mamwe minda, zvigadzirwa aivigirwa kuUnited States, Germany, Japan, South Korea, United Arab Emirates, South Africa, Taiwan uye dzimwe dzinopfuura 40 nyika uye nharaunda.

Reaction bonded silicon carbide (SiSiC): Kuomarara kweMoh i9.5, nekunyatso ramba kukurwa nekuora, kusamira zvakanaka kweabrasion uye anti-oxidation. Iine simba rakapetwa kana kana kashanu pane nitride yakasungirirwa silicon carbide. Hupenyu hwesevhisi ndeye 7 kusvika ku10 nguva yakareba kupfuura alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma.

PACKAGING:

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yeyakakura silicon carbide ceramic zvinhu zvitsva zvinogadziriswa muChina. SiC technical ceramic: Kuomarara kweMoh ndeye 9 (Kuoma kweMoh kutsva ndeye 13), nekupokana kwakanyanya kukukurwa nekuora, kunyura kwakanakisa - kuramba uye anti-oxidation. Hupenyu hwesevhisi yechigadzirwa cheSiC hwakareba 4 kusvika kashanu kupfuura 92% alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Iyo quotation process inokurumidza, kuendesa kwakavimbiswa uye mhando ndeyechipiri kune imwe. Isu tinogara tichishingirira kupikisa zvinangwa zvedu uye nekudzorera moyo yedu kunharaunda.