Silicon Carbide Ceramic mataira

Yakagadzirirwa kutsungirira matambudziko akanyanya ekushanda,silicon carbide tilesrave iro bhenji zvinhu zvemaindasitiri anoda kudzivirirwa kupfeka. Yayo yakasarudzika microstructure inopa yakasarudzika kuita mu:

- Inorema abrasion zones inobata coarse particulates (>5mm)

- High-impact classification & dewatering systems

- Corrosive midhiya yekufambisa mumakorari kugadzirisa & makemikari zvidyarwa

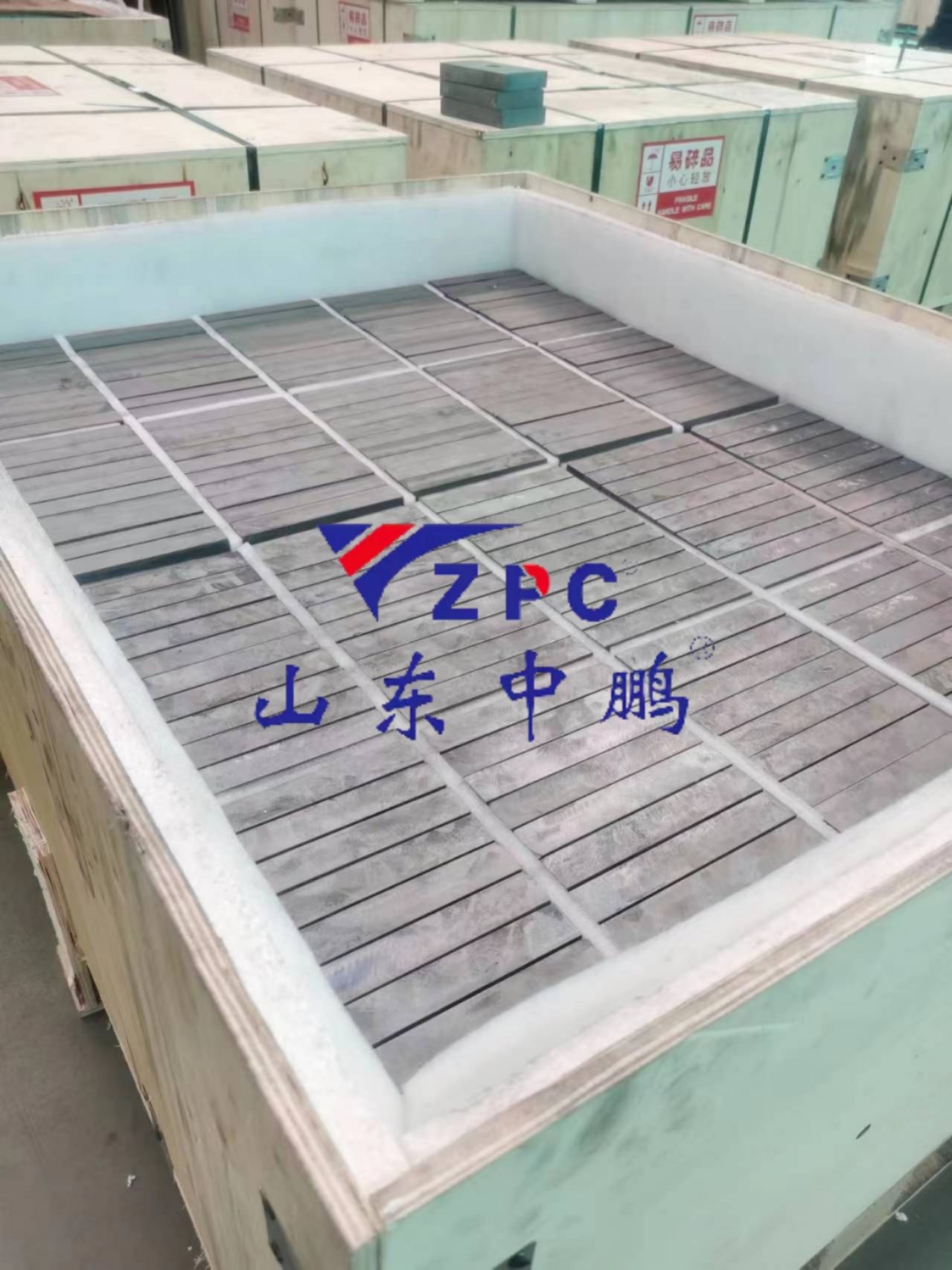

Kubva pasimbi mill slag conveyors kusvika kune mechanic chisimbiso zviso mukugadzirwa kwezvinhu,silicon carbide tileszvikamu zvinoshanda seakagadziridzwa nhumbi dzokurwa - kunyatso dzivirira dzakakosha mapoinzi ekupfeka uku uchichengetedza kugadzikana kwedimensional pasi pekunetseka kunoramba kuripo.

Sezvo kudiwa kuri kuwedzera kwesilicon carbide mataira, liner, uye pombi pamacheni ekugadzirisa zvicherwa, vatengi vanonzwisisa vanofanirwa kukoshesa aya mabhenji:

1. Kuumbwa Kwenhaka

Yedu yeGerman-yakabva musanganiswa inoedzwa kwakawanda kwekukukurwa kwevhu, kuwana kurasikirwa kwezvinhu pazasi 0.86㎝³ - chirevo chesilicon carbide mataira matrix kuperera.

2. Kuoma Verification Protocol

Silicon carbide mataira anoenda kutriaxial stress mepu, achiratidza 14.55±4.5 kuomarara kweMohs kutsva ne ≤2% MOR musiyano pamabhechi ekugadzira.

3. Density Precision Control

Substandard sintering inogadzira kusagadzikana kwechimiro. Yedu silicon carbide mataira maitiro anochengetedza 3.03±0.05g/㎝³ density kuburikidza neproprietary pressure-assisted reaction bonding, kubvisa subsurface voids.

4. Geometric Perfection

▸ Laser-yakasimbiswa pamusoro flatness (<0.02mm/m²)

▸ Mupendero weradius kuenderana (0.5±0.1mm)

▸ 100% crack/pore-free certification

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yeyakakura silicon carbide ceramic zvinhu zvitsva zvinogadziriswa muChina. SiC technical ceramic: Kuomarara kweMoh ndeye 9 (Kuoma kweMoh kutsva ndeye 13), nekupokana kwakanyanya kukukurwa nekuora, kunyura kwakanakisa - kuramba uye anti-oxidation. Hupenyu hwesevhisi yechigadzirwa cheSiC hwakareba 4 kusvika kashanu kupfuura 92% alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Iyo quotation process inokurumidza, kuendesa kwakavimbiswa uye mhando ndeyechipiri kune imwe. Isu tinogara tichishingirira kupikisa zvinangwa zvedu uye nekudzorera moyo yedu kunharaunda.