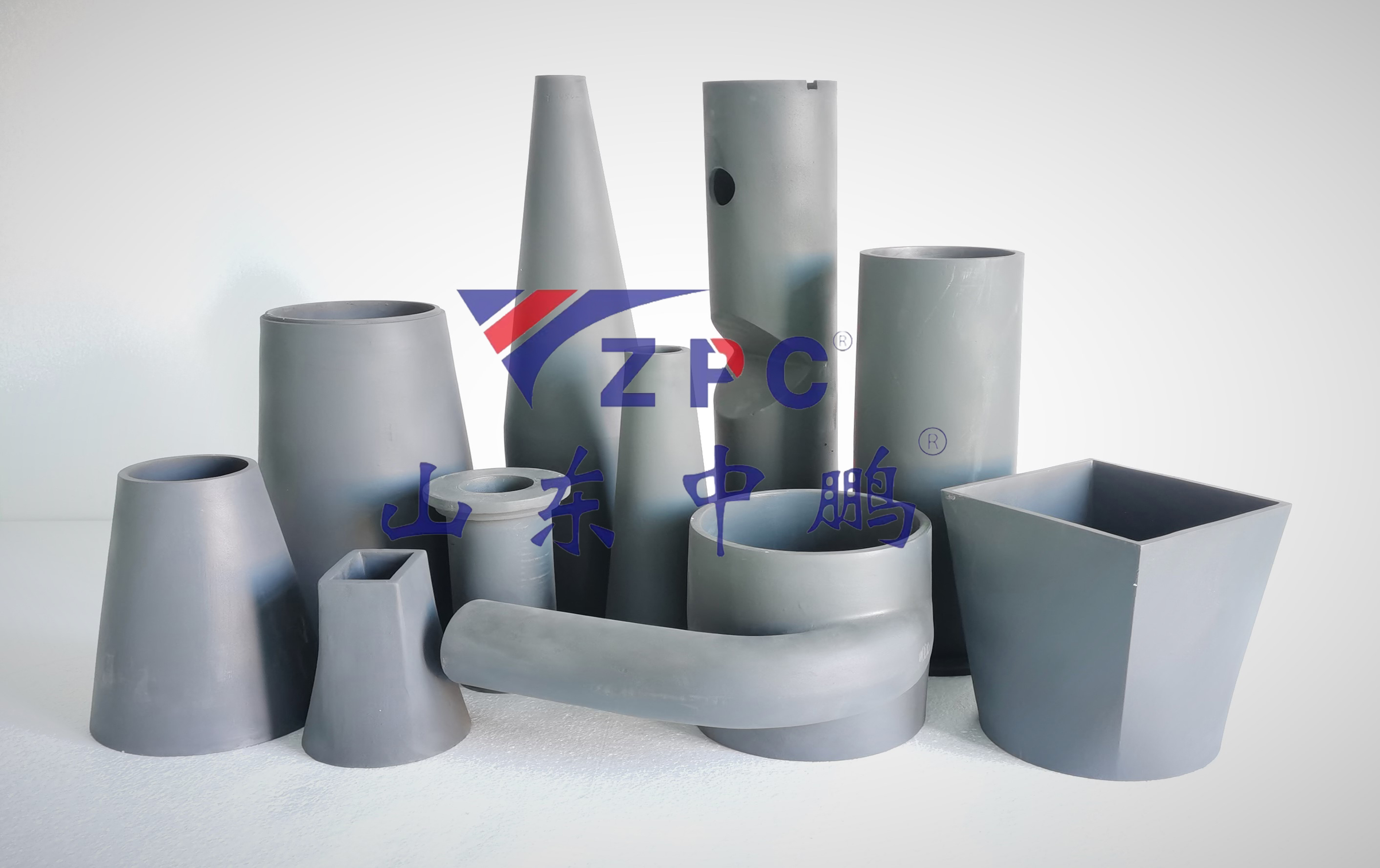

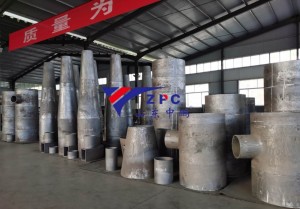

Silicon carbide ceramic liners

Silicon carbide kupfeka-resistant lining

Dhizaini Zvimiro zveSilicon Carbide (SiC) Wear-Resistant Liners:

(1) Yakakwenenzverwa Flow Path Dhizaini

Iyo yakatsetseka, yakakwenenzverwa contour kubva pakupinda kuenda kune yekubuda inoderedza kuyerera kuyerera, ichiita SiC liners kuchinjika kune akasiyana maindasitiri ekushandisa.

(2) Advanced Atomization

MechanismLiquids inoiswa maatomu kuita madonhwe akanaka kuburikidza nekudhumhana kwetangential uye zvishoma nezvishoma kutetepa helical nzvimbo dzeSiC liner, kuve nechokwadi chekuparadzira yunifomu yekupfapfaidza.

(3) Yakakwana, Yakavharwa-Yemahara Mamiriro

Iyo yakatwasuka-kuburikidza, coreless yekuyerera chiteshi inobvisa zvipingamupinyi zvemukati, kuwedzera fluid throughput mukati meakavharirwa pombi zviyero uku ichidzivirira kuvhara.

(4) Dual Spray Modes yekunatsiridza Kubudirira

Inotsigira zvese solid-cone uye hollow-cone yekupfapfaidza mapatani, ichipa mabheji ekuvhara akafara uye anti-kuvhara kuita kwekuita kwepamusoro-kushanda.

Core zvakanakira zvichienzaniswa nezvimwe zvinhu:

(1) Zvisingaenzaniswi Wear Resistance

Kuomarara: SiC liners inowana kuomarara kweMohs ye9.5 (vs. 8.0 yealuminium ceramics, 6.0 yehigh-chromium simbi), ichivagonesa kutsungirira kusakara kwakanyanya mumigodhi slurries, marasha emarasha, uye simbi hupfu.

Hupenyu hurefu: Hupenyu hwesevhisi hunodarika 5-10 × zvechinyakare zvinhu (semu rabha kana polyurethane liner) mune yakakwirira-impact application senge bhora zvigayo kana slurry pombi.

(2)Kuora uye Kemikari Inertness

Acid/Alkali Resistance: Inopikisa yakanyungudutswa sulfuric acid (98%), sodium hydroxide (50%), uye munyu wakanyunguduka (semuenzaniso NaCl-KCl pa800°C), nepo simbi dzinoita ngura nekukurumidza uye mapolima anodzikira.

Zero Kusvibiswa: Isinga-reactive nzvimbo inovimbisa kuchena mune semiconductor kana lithium bhatiri kugadzirwa, kusiyana nesimbi liner dzinowanzoita ion leaching.

(3) Kunyanya Kugadzikana Kwekupisa

Thermal Resilience: Inoshanda nguva dzose pa1,600 ° C (vs. alumina's 1,200 ° C muganho) nekuwedzera kushoma kwemafuta (CTE: 4.0 × 10⁻⁶/℃), kudzivirira kuputika mumoto kana kunyungudutsa mavira.

Thermal Shock Resistance: Inochengetedza kutendeseka pasi pekukurumidza kupisa kwekushisa (semuenzaniso kudzima kubva 1,000 ° C kusvika kukamuri tembiricha), kusiyana nebrittle ceramics.

(4)Energy Efficiency uye Lightweight Dhizaini

Yakaderera Friction: Yakakwenenzverwa SiC pamusoro (Ra <0.1 μm) inoderedza kusamira kwemvura ne30-50% kupesana nesimbi yakakasharara liner, kucheka pombi simba remagetsi.

Kuchengetedza Huremu: Density ye3.1 g/cm³ (vs. simbi's 7.8 g/cm³) inorerutsa kuisirwa uye inotsigira midziyo isingaremi muaerospace kana nhare dzekugadzirisa zvikamu.

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yeyakakura silicon carbide ceramic zvinhu zvitsva mhinduro muChina. SiC technical ceramic: Kuomarara kweMoh ndeye 9 (Kuoma kweMoh kutsva ndeye 13), nekupokana kwakanyanya kukukurwa nekuora, kunyura kwakanakisa - kuramba uye anti-oxidation. Hupenyu hwesevhisi yechigadzirwa cheSiC hwakareba 4 kusvika kashanu kupfuura 92% alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Iyo quotation process inokurumidza, kuendesa kwakavimbiswa uye mhando ndeyechipiri kune imwe. Isu tinogara tichishingirira kupikisa zvinangwa zvedu uye nekudzorera moyo yedu kunharaunda.