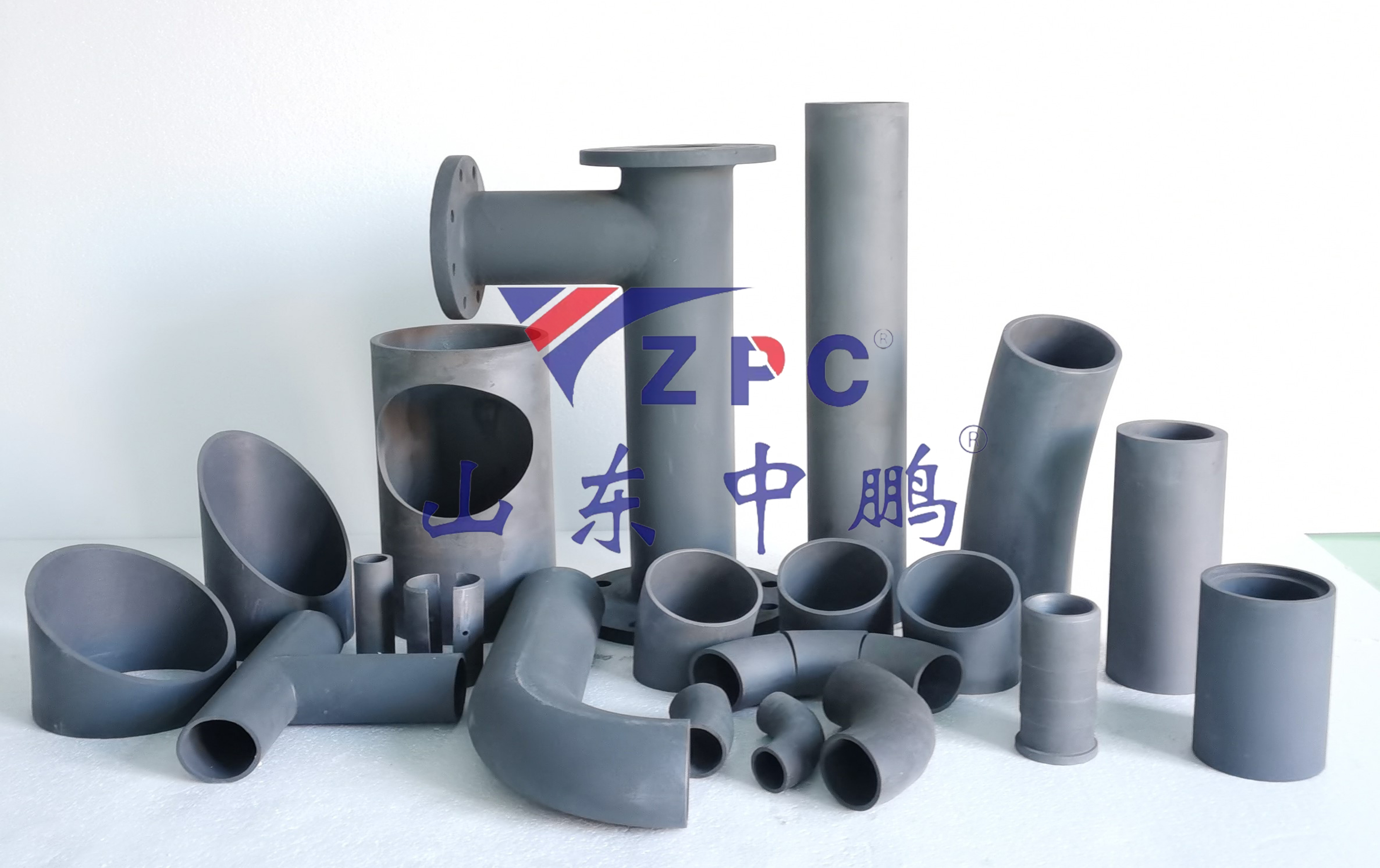

Silicon carbide ceramic lined kupfeka-resistant pombi uye hydrocyclone mumagetsi emagetsi

Silicon Carbide Ceramic Piping Systems: Reinventing Power Plant Infrastructure

Zvivakwa zvekugadzira magetsi zvinosangana nematambudziko ekushanda zvakanyanya, nemapombi epombi anogara:

- Kuenderera mberi kupisa bhasikoro (100–650°C)

-Abrasive particle velocities inopfuura 30 m/s

- pH misiyano kubva ku2-12 mune flue gasi scrubbers

- Cyclic pressure kuchinja (0–6 MPa)

Mapombi echinyakare esimbi uye epolymer anowanzo kutadza pasi peaya mamiriro, zvichiita kuti silicon carbide (SiC) ceramic kupfeka-inodzivirira pombi mhinduro yakagadziridzwa yezvidyarwa zvemagetsi zvemazuva ano.

Material Sayenzi Kubudirira

SiC ceramic mapaipi anosanganisa yakasarudzika zvivakwa zvakakosha kune simba chikamu mashandisirwo:

- Vickers Kuoma 28 GPa (4 × yakaoma kupfuura tungsten carbide)

- Wear Rate <0.1 mm³/N·m (ASTM G65)

- Thermal Conductivity 120 W/m·K (yakakwirira kune simbi isina tsvina)

- Kemikari Inertness (inoramba 98% H₂SO₄ pa300 ° C)

Operational Advantages muCritical Systems

1. Kubata Kwemarasha & Kutakura Madota

- Ramba kubva pa5-7 mm/gore kupfeka kubva pa60% solid-content slurry

- Chengetedza <5% kuderera kwekuyerera pamusoro pe10,000 maawa ekushanda

2. Flue Gasi Desulfurization (FGD)

- pH-inodzivirira kuita mu limestone slurry circuits

- Bvisa chloride-induced pitting corrosion

3. Fly Ash Conveyance

- 0.08 μm kushata kwepamusoro kunoderedza kunamatira

- Bata 50 tph kugona pa 35 ° inclination angles

Kuchinja Kweupfumi

Vagadziri vezvirimwa vanoshuma mabhenefiti anoyerwa:

- 70% kuderedzwa mukutsiviwa kwepombi isina kurongwa

- 55% yakaderera mari yekuchengetedza basa

- 18% yakavandudza kupisa kwemafuta mumhepo inotenderera

- 40% yakawedzerwa mararamiro ehupenyu vs. alloy dzimwe nzira

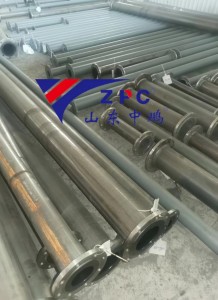

Installation & Operational Flexibility

- Modular 1-6 m zvikamu zvine flanged / tambo yekubatanidza

- 60% kuderedza uremu vs. simbi yakaenzana (3.2 g/cm³ density)

- Retrofittable kune iripo pombi inotsigira uye hangers

- Inopindirana neakangwara ekutarisa masisitimu ekufembera kufanotaura

Ramangwana-Yakatarisana Magadzirirwo

Inotevera-chizvarwa SiC pombi mhinduro dzinobatanidza:

- Gradient porosity yekupisa kushushikana kuderedza

- Conductive misiyano ye electrostatic kunaya

- Hybrid ceramic-elastomer majoini ekudedera kunyorova

-Kuzvichenesa pamusoro nano-textures

Kubva pazvidyarwa zvinopiswa nemarasha kuenda kumarara-kune-simba zvivakwa, silicon carbide ceramic pombi inotsanangurazve kuvimbika mumagetsi emagetsi. Musanganiswa wavo wakasiyana-siyana wekusimba kwemagetsi, kutsungirira kwekupisa, uye kugadzikana kwemakemikari kunovimbisa kuenderera mberi kwekushanda pasi pemamiriro ezvinhu akanyanya - kushandura zvirongwa zvekugadzirisa kubva pakugadzirisa zvinogadzirisa kusvika kune zvakarongwa, zvinodhura-zvinobudirira kusimudzira.

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yeyakakura silicon carbide ceramic zvinhu zvitsva zvinogadziriswa muChina. SiC technical ceramic: Kuomarara kweMoh ndeye 9 (Kuoma kweMoh kutsva ndeye 13), nekupokana kwakanyanya kukukurwa nekuora, kunyura kwakanakisa - kuramba uye anti-oxidation. Hupenyu hwesevhisi yechigadzirwa cheSiC hwakareba 4 kusvika kashanu kupfuura 92% alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Iyo quotation process inokurumidza, kuendesa kwakavimbiswa uye mhando ndeyechipiri kune imwe. Isu tinogara tichishingirira kupikisa zvinangwa zvedu uye nekudzorera moyo yedu kunharaunda.