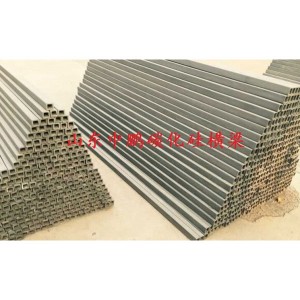

hombe saizi silicon carbide rollers OD82mm

Silicon carbide matanda uye rollers anoshandiswa sekurodha mafuremu mu porcelain anogadzira kilns, uye anogona kutsiva yakajairwa oxide bonded silicon ndiro uye mullite positi sezvo vaine zvakanaka zvakanaka senge nzvimbo dzekuchengetedza, mafuta, simba uye zvakare ipfupi nguva yekupfura, uye nguva yehupenyu hwezvishandiso izvi akati wandei dzimwe ndiyo yakanakira honi fenicha. Silicon carbide beam inonyanya kushandiswa semutoro unotakura nhengo dzetunnel kiln, shuttle kiln uye kaviri nzira kiln. Inogona zvakare kushandiswa sechoto fenicha mune ceramic uye refractory indasitiri. RBSiC (SiSiC) ine yakanakisa yekupisa conductivity, saka inowanikwa kuchengetedza simba nehuremu hushoma hwemoto yekupisa.

Miti ine yakakwira - tembiricha inotakura simba rehombe, yenguva refu yekushandiswa pasina kubhenda deformation, kunyanya yakakodzera kune tunnel kilns, shuttle kiln, mune maviri - layer roller kiln uye imwe indasitiri yevira remutoro - inotakura chimiro chefuremu. Makirabhu anoshanda kune mazuva ese - anoshandiswa ceramics, sanitary porcelain, Kuvaka Ceramic, Magnetic zvinhu uye yakanyanya tembiricha yekupisa nzvimbo yeroller kiln.

| ITEM | RBSIC (SISIC) | SSIC | |

|---|---|---|---|

| UNIT | DATA | DATA | |

| MAX TEMPERATURE YEKU APPLIC ATION | C | 1380 | 1600 |

| DENSITY | g/cm3 | >3.02 | >3.1 |

| Vhura POROSITY | % | <0.1 | <0.1 |

| KUBENDA SIMBA | Mpa | 250(20c) | >400 |

| MPa | 280 (1200 C) | ||

| MODULUS OF ELASTICITY | Gpa | 330 (20c) | 420 |

| GPA | 300 (1200c) | ||

| THERMAL CONDUCTIVITY | W/mk | 45 (1200 c) | 74 |

| COEFFICIENT OF THERMAL EXPANSION | K x 10 | 4.5 | 4.1 |

| VICKERS HARDNESS HV | Gpa | 20 | 22 |

| ACID ALKALINE – PROFF |

Hunhu:

* High abrasion kuramba

*Kunyanya kushanda nesimba

* Hapana deformation pasi pekupisa kwakanyanya

* Yakanyanya kushivirira tembiricha 1380-1650 degree celsius

*Corrosion resistance

*Simba rekukotama rakakwirira pasi pe1100 degree:100-120MPA

Shandong Zhongpeng Special Ceramics Co., Ltd ndeimwe yeyakakura silicon carbide ceramic zvinhu zvitsva zvinogadziriswa muChina. SiC technical ceramic: Kuomarara kweMoh ndeye 9 (Kuoma kweMoh kutsva ndeye 13), nekupokana kwakanyanya kukukurwa nekuora, kunyura kwakanakisa - kuramba uye anti-oxidation. Hupenyu hwesevhisi yechigadzirwa cheSiC hwakareba 4 kusvika kashanu kupfuura 92% alumina zvinhu. Iyo MOR yeRBSiC ndeye 5 kusvika 7 nguva iyo yeSNBSC, inogona kushandiswa kune mamwe maumbirwo akaoma. Iyo quotation process inokurumidza, kuendesa kwakavimbiswa uye mhando ndeyechipiri kune imwe. Isu tinogara tichishingirira kupikisa zvinangwa zvedu uye nekudzorera moyo yedu kunharaunda.