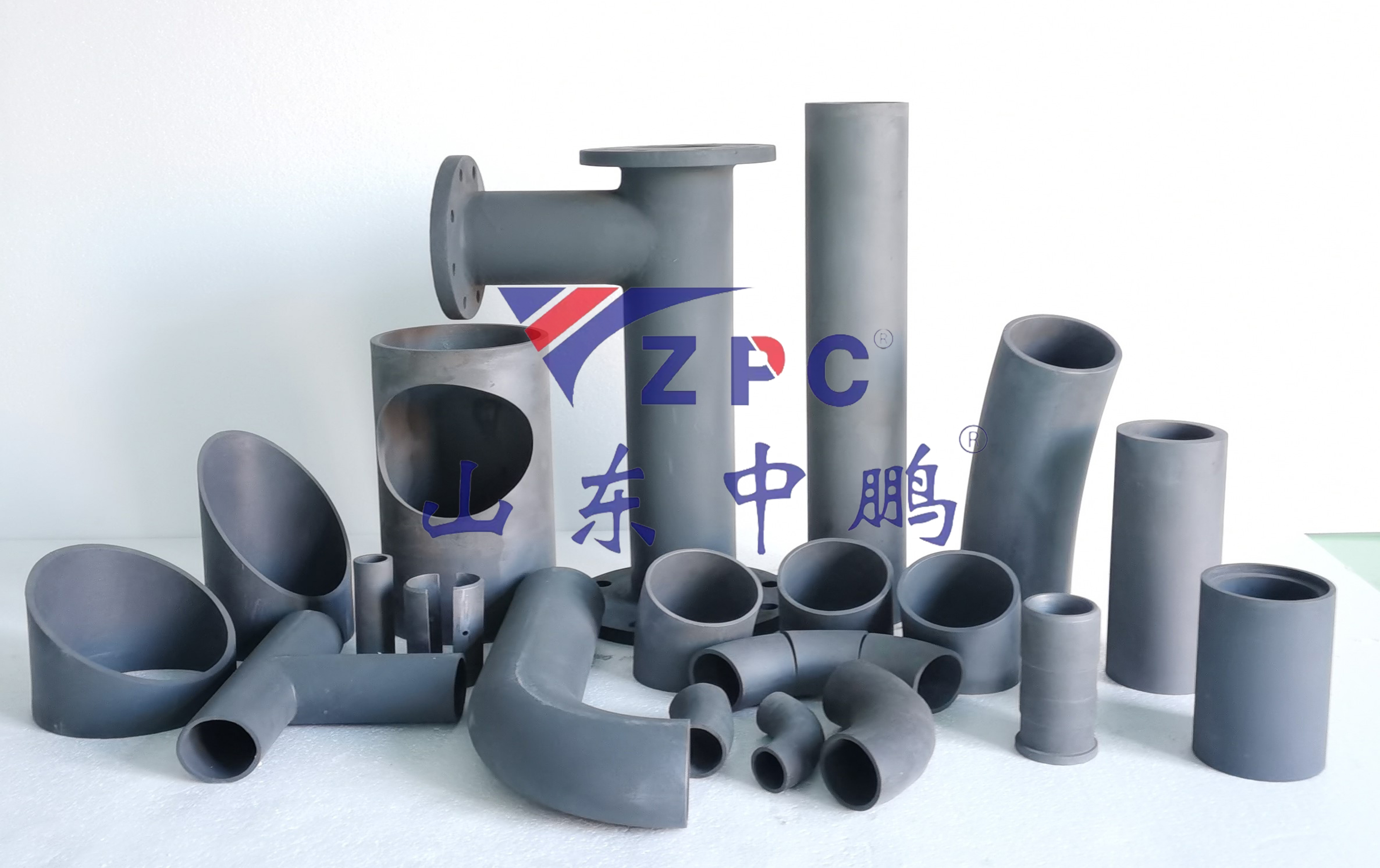

Tubi et hydrocycloni resistentes attritu, ceramicis carburis silicii obducti, in stationibus electricis

Systema Tuborum Ceramicorum Carbidi SiliciiInfrastructuram Stationis Electricae Reinventando

Installationes energiae generandae gravissimas difficultates operationales subeunt, cum systemata fistularum perdurare possint:

- Continua cyclicatio thermalis (100–650°C)

- Velocitates particularum abrasivarum excedentes 30 m/s

- variationes pH ab 2–12 in depuratoribus gasorum fumariorum

- Fluctuationes pressionis cyclicae (0–6 MPa)

Tubulaturae metallicae et polymericae traditionales sub his condicionibus saepe deficiunt, ita ut tubuli ceramici detritioni resistentes e carburo silicii (SiC) solutio artificiosa pro centralibus electricis modernis sint.

Scientia Materialium Perruptio

Tubi ceramici SiC proprietates singulares, quae ad usus sectoris energiae necessariae sunt, coniungunt:

- Duritia Vickers 28 GPa (quattuor× durior quam carburum tungstenum)

- Frequentia detritionis <0.1 mm³/N·m (ASTM G65)

- Conductivitas thermalis 120 W/m·K (superior chalybe inoxidabili)

- Inertia Chemica (resistit 98% H₂SO₄ ad 300°C)

Commoda Operativa in Systematibus Criticis

1. Tractatio Carbonis et Transportatio Cineris

- Detritionem erosivam 5–7 mm/annum ex luto solido 60% sustinere

- Reductionem fluxus <5% per 10,000 horas operationis conserva.

2. Desulfuratio Gasorum Combustibilium (FGD)

- pH resistentia in circuitibus luti calcarii

- Corrosionem foveolarem chlorido-inductam elimina.

3. Cineris Volantis Transportatio

Asperitas superficiei 0.08 μm adhaesionem particularum minuit

- Capacitatem 50 tph ad angulum inclinationis 35° tractare

Transformatio Oeconomica

Operarii officinarum utilitates mensurabiles referunt:

- 70% reductio in substitutionibus tuborum improvisis

- Sumptus laboris sustentationis 55% minores

- Efficacia thermalis in cyclis vaporis 18% aucta

- Vita systematis 40% extensa comparata cum alternativis mixturarum metallorum

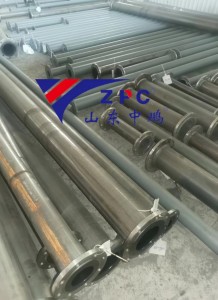

Installationis et Flexibilitatis Operationis

- Sectiones modulares 1–6 m cum nexibus flangiatis/filetatis

- 60% ponderis diminutio comparata cum aequivalentibus chalybis (densitas 3.2 g/cm³)

- Ad sustentacula et suspensiones tuborum iam exstantia adaptari potest

- Compatibilis cum systematibus monitoriis callidis ad praedictionem detritionis

Innovationes in Futurum Intentae

Solutiones fistularum SiC novae generationis haec integrant:

- Porositas gradiens ad mitigationem tensionis thermalis

- Variationes conductivae pro praecipitatione electrostatica

- Articuli hybridi ceramici-elastomeri ad vibrationes mitigandas

- Nano-texturae superficiales autopurgantes

Ab officinis carbonariis ad officinas energiae residuae convertendae, tubi ceramici e carburo silicii firmitatem in infrastructura electrica denuo definiunt. Singularis earum coniunctio firmitatis mechanicae, tolerantiae thermalis, et stabilitatis chemicae operationem continuam sub condicionibus extremis praestat – transformans programmata sustentationis a reparationibus reactivis ad emendationes planificatas et sumptibus efficaces.

Shandong Zhongpeng Special Ceramics Co., Ltd. est una ex maximis solutionibus novorum materiarum ceramicarum e carburo silicii in Sinis. Ceramica technica SiC: duritia Moh est 9 (nova duritia Moh est 13), cum excellenti resistentia erosioni et corrosioni, excellenti resistentia abrasionis et anti-oxidationis. Vita utilis producti SiC 4 ad 5 vicibus longior est quam materiae 92% aluminae. MOR RBSiC 5 ad 7 vicibus est maior quam SNBSC, ita ut ad formas complexiores adhiberi possit. Processus pretii celer est, traditio promissa est, et qualitas nulli secunda. Semper perseveramus in propositis nostris provocandis et corda nostra societati reddimus.