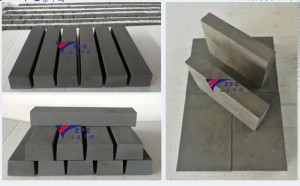

Tegulae ceramicae carburi silicii RBSC

Tegulae ceramicae carburi silicii RBSCpraecipua solutio ad detritionem et corrosionem in ambitus industrialibus difficilibus pugnandas exstiterunt. Hae tegulae et tegumenta ceramica artificiosa praebent efficaciam incomparabilem in systematibus tractationis materiarum, vitam instrumentorum extendentes dum efficientiam operationis per processus criticos optimizant.

Superioritas Ingeniaria

Nostrae partes e carburo silicii (SiC) accurate fabricatae proprietatibus singularibus excellunt:

- Duritia Mohs 9.5 (13 in scala renovata) ad extremam resistentiam attritionis

- Tenacitate fracturae 4–5× maior quam alternativae SiC nitrido-iunctae

- Vita utilis 5–7× longior comparata cum tegumentis aluminae traditis

- Inertia chemica contra acida, alcalia, et solventia organica (pH 0–14)

Stabilitas thermalis integritatem servans ab -60°C ad 1650°C

Solutiones Protectionis Personalisatae

Crassititibus ab 8 ad 45 mm praesto, nostrae tegumenta ceramicae variis requisitis operationalibus accommodantur:

- Configurationes resistentibus impactibus pro canalibus et infundibulis

- Superficies frictionis humilis pro systematibus vecturae

- Gradus altae puritatis ad usus cibarios/pharmaceuticos

- Variantes electrice insulantes pro ambientibus explosivis

Applicationes Perfunctione Impulsae

1. Systema Tractationis Materiarum

- Fistulae luti cum erosione 90% reducta

- Trommellae fodinales cum cyclis servitii 3× extensis

- Cyclones officinarum cementi superviventes plus quam 50,000 horas operationis

2. Instrumenta Processus

- Tegumenta pulverisatoris carbonis resistentia impactibus particularum 120 m/s

- Vasa reactorum chemicorum media corrosiva tractantia

- Ductus chalybis ferrei cineribus volatilibus abrasivis resistenti

3. Partes Speciales

- Tegumenta laminarum rotoris pro separatoribus centrifugalibus

- Laminae detritionis ad biomassa tractanda

- Inserta formae singularis ad geometrias complexas aptata

Impactus Oeconomicus

Transitio ad tegumenta carburi silicii utilitates mensurabiles demonstrat:

- 60–80% reductio in tempore inoperabili non planificato

- Sumptus sustentationis per totam vitam 45% minores

- 30% energiae conservatio per fluxum materiae optimizatum

- 90% partium detritarum redivivibilitas

Installatio et Adaptabilitas

Ad integrationem perfectam designatum:

- Systema tegularum modularium cum designis inter se connexis

- Epoxy altae firmitatis vel fixatio mechanica

- Officia machinationis et adaptationis in situ

- Compatibilitas monitorationis detritionis in tempore reali

Innovationes ad Futurum Paratae

Tegumenta carburi silicii novae generationis haec comprehendunt:

- Structurae densitatis gradientis ad absorptionem impetus

- Curae superficiales autolubricantes

- RFID-adiuvata vestigatio detritionis

- Systemata composita hybrida ceramica-metallica

Ab operationibus fodinarum ad officinas chemicas tractandas, tegumenta ceramica carburi silicii novum exemplar in protectione contra detritionem industrialem repraesentant. Singularis earum coniunctio firmitatis mechanicae, stabilitatis chemicae, et tolerantiae thermalis perfunctionem instrumentorum transformat – sumptus cycli vitae minuendo dum firmitatem productionis in asperrimis condicionibus operandi mundi auget.

Shandong Zhongpeng Special Ceramics Co., Ltd. est una ex maximis solutionibus novorum materiarum ceramicarum e carburo silicii in Sinis. Ceramica technica SiC: duritia Moh est 9 (nova duritia Moh est 13), cum excellenti resistentia erosioni et corrosioni, excellenti resistentia abrasionis et anti-oxidationis. Vita utilis producti SiC 4 ad 5 vicibus longior est quam materiae 92% aluminae. MOR RBSiC 5 ad 7 vicibus est maior quam SNBSC, ita ut ad formas complexiores adhiberi possit. Processus pretii celer est, traditio promissa est, et qualitas nulli secunda. Semper perseveramus in propositis nostris provocandis et corda nostra societati reddimus.