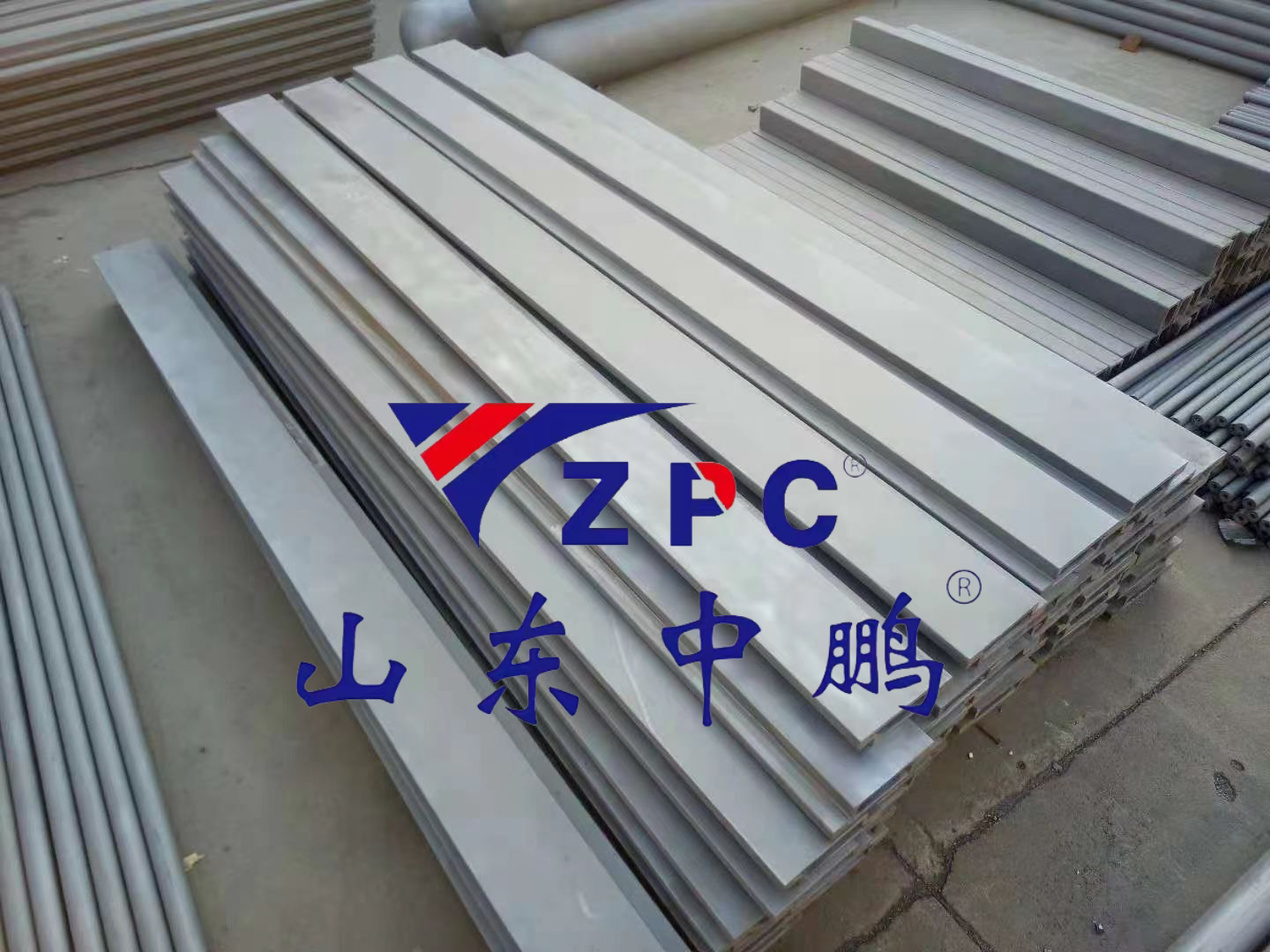

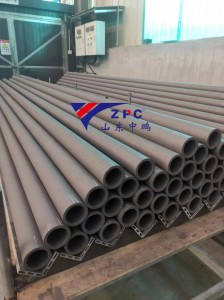

Silicon carbide ibé

Igwe ihe mkpuchi seramiiki silicon carbide (R-SiC) na-emeghachi omumeapụtala dị ka ihe dị mkpa na sistemu nhazi ọkụ ọgbara ọhụrụ, ọkachasị n'ichepụta batrị lithium, mmepụta ceramik dị elu, yana njiri ihe magnetik ziri ezi. Rollers ndị a pụrụ iche na-akọwapụta ụkpụrụ arụmọrụ n'ime ọkụ ụlọ ọrụ na-ekpo ọkụ dị elu site n'ịkwado ihe ịma aka ndị bụ isi na nkwụsi ike okpomọkụ na ịdịte aka n'ibu.

Arụmọrụ Thermal enweghị atụ

Ezubere ka ọ na-arụ ọrụ na-aga n'ihu na 1450-1600 ° C - dị elu nke ukwuu karịa ihe mkpuchi alumina ọdịnala - R-SiC rollers na-ejigide nkenke akụkụ ọbụlagodi n'okpuru ịgba ígwè ọkụ. Microstructure ha pụrụ iche na-enyere:

• Ịdị n'otu na-ebufe okpomọkụ ngwa ngwa (± 5°C n'ogologo rola)

• Ịnagide 100+ thermal ujo okirikiri (1400°C ↔ ụlọ okpomọkụ)

• Nrụrụ efu na-akpụ akpụ na okpomoku dị elu kwụgidere

Akọwagharịrị ngwa dị egwu

1. Mmepụta batrị lithium

- Ndozi ziri ezi maka sentering ihe electrode

- Ijikwa kathodes NMC/LFP enweghị mmetọ

- arụ ọrụ kwụsiri ike na ibelata ikuku

2. Nhazi ceramics dị elu

- Nkwado na-enweghị agha maka taịlị usoro buru ibu (ihe ruru 1.5 × 3m)

- njikwa ọsọ na-agbanwe agbanwe na ahịrị glazing sanitaryware

- Emecha elu na-enweghị akara (Ra <0.8μm)

3. Ịmepụta ihe ndọta

- Ntugharị na-enweghị ịma jijiji maka ịgba mbọ ferrite sintering

- Inertness kemịkalụ na gburugburu ikuku nwere hydrogen

Uru arụmọrụ

Ikike ibu: Na-akwado 3-5× dị arọ ka ukwuu kwa nkeji ogologo vs. metal alloy rollers

Nguzogide nrụrụ: Na-edobe <0.05mm/m kwụ ọtọ mgbe awa ọrụ 10,000 gasịrị

Ịrụ ọrụ ike: 18-22% belatara ike ọkụ ọkụ site na nkesa ọkụ kachasị mma

Ndakọrịta ụlọ ọrụ Cross-Industry: Enwere ike imeghari ka ọ bụrụ ebe a na-ebugharị ụgbọ ala, igwe mkpuchi mkpuchi multi-layer, na ọkụ ọwara ngwakọ.

Ịdịgide akụ na ụba

Mgbe ị na-achọ 30-40% ntinye ego mbụ dị elu karịa ndị na-agbagharị agbagharị, R-SiC ngwọta na-egosi:

- 70% ogologo oge ọrụ (afọ 5-7 vs. 2-3 afọ)

- 90% recyclaability site na usoro mgbake okpomọkụ

- 60% na-akwụ ụgwọ mmezi dị ala site na ebe abrasion na-eguzogide

Ime Njikere Ọdịnihu

Rollers R-SiC nke oge a na-agụnye:

- Laser-kanyere nsuso grooves maka akpaghị aka mmepụta ahịrị

- Porosity nwere ike ịhazi maka permeability ikuku

- Integrated thermal sensọ maka smart kiln arụmọrụ

Ndị a na nkà na ụzụ ọganihu ọnọdụ mmeghachi omume-sintered silicon carbide rollers dị ka oké mkpa akụrụngwa na-esote-ọgbọ ulo oru kpo oku usoro, na-enyere ndị na-emepụta iji nweta tighter okpomọkụ akara, elu ngwaahịa agbanwe agbanwe, na-adigide mmepụta workflows gafee multiple elu-tech ndi.

Shandong Zhongpeng Special Ceramics Co., Ltd bụ otu n'ime nnukwu silicon carbide seramiiki ihe ngwọta ọhụrụ na China. SiC technical ceramic: Moh's hardness is 9 (New Moh's hardness is 13), na ezigbo nguzogide mbuze na corrosion, ọmarịcha abrasion - nguzogide na mgbochi oxidation. Ndụ ọrụ ngwaahịa SiC bụ 4 ruo 5 ugboro ogologo karịa 92% alumina ihe onwunwe. MOR nke RBSiC bụ 5 ruo 7 ugboro karịa nke SNBSC, enwere ike iji ya mee ihe maka ụdị mgbagwoju anya. Usoro nhota dị ngwa ngwa, nnyefe dị ka e kwere ná nkwa na àgwà bụ nke abụọ na ọ dịghị. Anyị na-anọgidesi ike mgbe niile n'ịgba ebumnobi anyị aka ma na-enyeghachi obi anyị azụ n'obodo.