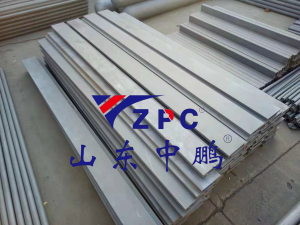

Akụrụngwa Kiln Silicon carbide Beams na rollers

ZPC-RBSiC (SiSiC) obe obe nwere ike dị elu yana enweghị nrụrụ ọbụna na oke okpomọkụ. Na kwa ibé na-egosipụta ogologo ọrụ ndụ. Osisi ndị ahụ bụ arịa ụlọ kiln kacha dabara adaba maka uwe ịdị ọcha na ngwa igwe eletrik. Shang mei RBSiC (SiSiC) nwere ezigbo ikuku ọkụ, yabụ ọ dị iji chekwaa ike yana obere ibu nke ụgbọ ala kiln.

Silicon carbide ibé na rollers na-eji dị ka loading okpokolo agba na poselin na-emepụta kilns, na nke nwere ike dochie nkịtị oxide bonded silicon efere na mullite post dị ka ha nwere ezi uru dị ka ịzọpụta oghere, mmanụ ụgbọala, ike na-adị mkpụmkpụ oge ịgba égbè, na ndụ oge nke ihe a bụ ọtụtụ ugboro nke ndị ọzọ na ọ bụ ezigbo kiln ngwá ụlọ. A na-ejikarị silicon carbide beam eme ihe dị ka ibu na-ebu ndị otu ọwara kiln, kiln ụgbọ ala na kiln ọwa abụọ. Enwere ike iji ya dị ka arịa ụlọ ọkụ na seramiiki na ụlọ ọrụ refractory.

Ibe na elu - okpomọkụ amị ikike nke nnukwu, ogologo oge ojiji na-enweghị ekwe deformation, karịsịa adabara ọwara kilns, shuttle kiln, na abụọ - oyi akwa rola kiln na ndị ọzọ ulo oru oku ibu - ibu Ọdịdị nke etiti. Klọb na-emetụta kwa ụbọchị - ceramik eji eme ihe, poselin ịdị ọcha, seramiiki ụlọ, ihe ndọta na mpaghara ọkụ dị elu nke igwe rola.

| ITEM | RBSIC (SISIC) | SSIC | |

|---|---|---|---|

| UNIT | DATA | DATA | |

| Oke okpomọkụ nke ngwa ngwa | C | 1380 | 1600 |

| OKWU | g/cm3 | > 3.02 | > 3.1 |

| Oghere emeghe | % | <0.1 | <0.1 |

| IKE na-ehulata | Mpa | 250 (20c) | > 400 |

| MPa | 280 (1200 C) | ||

| MODULUS OF elaSTICITY | Gpa | 330 (20c) | 420 |

| GPA | 300 (1200c) | ||

| OKWU OKWU | W/mk | 45 (1200 c) | 74 |

| NKWUKWU nke Mgbasa ọkụ ọkụ | K x 10 | 4.5 | 4.1 |

| Ụlọ ọrụ VICKERS HARDNESS HV | Gpa | 20 | 22 |

| Acid ALKALINE – PROFF |

Njirimara:

* Nnukwu nguzogide abrasion

* Oke ike arụmọrụ

* Enweghị nrụrụ n'okpuru oke okpomọkụ

* Okpomoku kacha elu 1380-1650 Celsius

* Nguzogide corrosion

* Ike na-ehulata dị elu n'okpuru ogo 1100: 100-120MPA

Shandong Zhongpeng Special Ceramics Co., Ltd bụ otu n'ime nnukwu silicon carbide seramiiki ihe ngwọta ọhụrụ na China. SiC technical ceramic: Moh's hardness is 9 (New Moh's hardness is 13), na ezigbo nguzogide mbuze na corrosion, ọmarịcha abrasion - nguzogide na mgbochi oxidation. Ndụ ọrụ ngwaahịa SiC bụ 4 ruo 5 ugboro ogologo karịa 92% alumina ihe onwunwe. MOR nke RBSiC bụ 5 ruo 7 ugboro karịa nke SNBSC, enwere ike iji ya mee ihe maka ụdị mgbagwoju anya. Usoro nhota dị ngwa ngwa, nnyefe dị ka e kwere ná nkwa na àgwà bụ nke abụọ na ọ dịghị. Anyị na-anọgidesi ike mgbe niile n'ịgba ebumnobi anyị aka ma na-enyeghachi obi anyị azụ n'obodo.