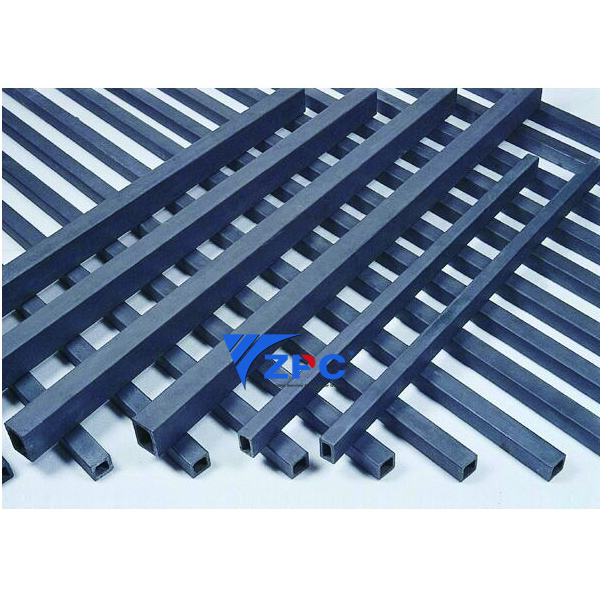

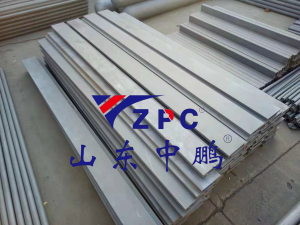

SiC Beam

Mmeghachi omume jikọtara Silicon Carbide ike dị elu kwụ ọtọ Sisic/ Rbsic Rollers na beams

A na-ejikarị mmeghachi omume sintering silicon carbide ceramics roller maka ụlọ ọrụ batrị lithium, poselin kwa ụbọchị, poselin ịdị ọcha, seramiki ụlọ na ihe ndọta, dị ka igwe mkpuchi mkpuchi, nnukwu okpomọkụ na-ere ọkụ nwere ezigbo kiln, yana ogologo ndụ ọrụ. Ọ nwere elu okpomọkụ ike, thermal ujo na-eguzogide, elu okpomọkụ creep eguzogide, siri ike na-eguzogide, ezigbo eyi nguzogide.

Klọb na-emetụta kwa ụbọchị - ceramik eji eme ihe, poselin ịdị ọcha, seramiiki ụlọ, ihe ndọta na mpaghara ọkụ dị elu nke igwe rola.

| Nkọwapụta Ngwaahịa Silicon Carbide: | ||||

| Ihe | Nkeji | SSIC | RBSIC SISIC | R-SIC |

| Ịdị ọcha | (%) | ≥ 99 | ≥90% | ≥ 99 |

| Ngwa okpomọkụ | ºC | 1700 | 1380 | 1650 |

| Njupụta | g/CM2 | ≥3.10-3.15 | ≥3.02 | 2.65-2.75 |

| Mepee porosity | % | ≤0.1 | ≤0.1 | |

| Isi ike | ≥92 HRA | 2400kg/mm2 | 1800-2000 n'arọ / mm2 | |

| Ike na-ehulata | MPa | 400-580 | 250 (20ºC) | ≥300 |

| 281 (1200ºC) | ||||

| Ike ọdụdọ | Mpa | ≥200 | ≥190 | |

| modul nke elasticity | GPA | 400 | 332 (20ºC) | 80-100 (20ºC) |

| 300 (1200ºC) | 90-110 (1200ºC) | |||

| Nrụpụta okpomọkụ | W/mk | 100-120 | 45 (1200ºC) | 36 |

| Ọnụọgụ nke mgbasawanye thermal | K1X 106 | 4.2 | 4.5 | 4.6 |

| Isi ike | Gpa | >25 | 13 | |

| Acid&Ikali nguzogide | Magburu onwe | Magburu onwe | Magburu onwe | |

| Nkọwapụta ngwaahịa SiC: | ||||

| Ihe | Nkeji | OC-1 | OC-2 | MC-3 |

| SiC | (%) | ≥90 | ≥86 | ≥80 |

| Porosity pụtara | (%) | ≤10 | ≤13 | ≤16 |

| Njupụta | g/CM2 | ≥2.66 | ≥2.63 | ≥2.6 |

| Ngwa okpomọkụ | ºC | ≥1680 | ≥1620 | ≥1550 |

| Ọnụọgụ nke mgbasawanye thermal | aX 10-6/ºC | ≤4.8 | ≤5.0 | ≤5.5 |

| Na-ehulata Ike | 1200ºC | ≥45 | ≥40 | ≥30 |

Shandong Zhongpeng Special Ceramics Co., Ltd bụ otu n'ime nnukwu silicon carbide seramiiki ihe ngwọta ọhụrụ na China. SiC technical ceramic: Moh's hardness is 9 (New Moh's hardness is 13), na ezigbo nguzogide mbuze na corrosion, ọmarịcha abrasion - nguzogide na mgbochi oxidation. Ndụ ọrụ ngwaahịa SiC bụ 4 ruo 5 ugboro ogologo karịa 92% alumina ihe onwunwe. MOR nke RBSiC bụ 5 ruo 7 ugboro karịa nke SNBSC, enwere ike iji ya mee ihe maka ụdị mgbagwoju anya. Usoro nhota dị ngwa ngwa, nnyefe dị ka e kwere ná nkwa na àgwà bụ nke abụọ na ọ dịghị. Anyị na-anọgidesi ike mgbe niile n'ịgba ebumnobi anyị aka ma na-enyeghachi obi anyị azụ n'obodo.