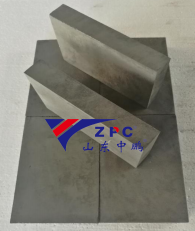

Fale-falen fale-falen fale-falen fale-falen fale-falen silicon carbide mai jurewa sawa, masu siyar da kayan kwalliya da Alumina Ceramic Tiles Suppliers, Masu siye,

Reaction bonded silicon carbide (SiSiC ko RBSIC) shine ingantaccen kayan jure lalacewa, wanda shine

musamman dace da karfi abrasive, m barbashi, rarrabuwa, maida hankali, dehydration da kuma

sauran ayyuka. Ana amfani dashi sosai a masana'antar hakar ma'adinai, masana'antar karfe, masana'antar sarrafa murjani, sinadarai

masana'antu, albarkatun kasa-yin masana'antu, inji sealing, surface sandblasted jiyya da reflector da dai sauransu.

Godiya ga kyakkyawan taurin da juriya mai lalacewa, zai iya kare yadda ya kamata bangaren da ake buƙatar lalacewa

kariya, don tsawaita rayuwar sabis na kayan aiki.

Yadda ake ganowa da nemo manyan faranti masu jure wa siliki carbide, tayal, layi?

Silicon carbide fale-falen fale-falen fale-falen fale-falen fale-falen buraka, masu layi, bututu suna ƙara yin amfani da su a cikin masana'antar hakar ma'adinai.

Abubuwan da ke biyowa don tunani ne:

1. Formula da tsari:

Akwai tsarin SiC da yawa akan kasuwa. Muna amfani da ingantattun hanyoyin Jamusanci. A cikin gwaje-gwajen gwaje-gwaje masu girma, samfuran mu Yazara ㎝³ asarar na iya kaiwa 0.85 ± 0.01;

2. Tauri:

Ana samar da fale-falen SiC a cikin ZPC: sabon ƙarfin Mohs: 14.55 ± 4.5 (MOR, psi)

3. Yawa:

Matsakaicin yawan tile na ZPC SiC shine kusan 3.03+0.05.

4. Girma da Surface:

SiC tiles da aka samar a cikin ZPC ba tare da fasa ba da pores, tare da filaye masu lebur da gefuna da sasanninta.

5. Kayan ciki:

Silicon carbide masu jure lalacewa/tiles suna da kyau kuma iri ɗaya kayan ciki da na waje.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Ƙayyadaddun bayanai:

| Abu | Naúrar | Bayanai |

| Zazzabi na aikace-aikace | ℃ | 1380 ℃ |

| Yawan yawa | G/cm3 | · 3.02 |

| Bude porosity | % | 0.1 |

| Karfin lankwasawa -A | Mpa | 250 (20 ℃) |

| Karfin lankwasawa -B | MPa | 280 (1200 ℃) |

| Modulus na elasticity-A | GPA | 330 (20 ℃) |

| Modulus na elasticity -B | GPA | 300 (1200 ℃) |

| Ƙarfafawar thermal | W/mk | 45 (1200 ℃) |

| Coefficient na thermal fadadawa | K-1 × 10-6 | 4.5 |

| Tsauri | / | 13 |

| Acid-proof alkaline | / | m |

■Akwai Siffa da Girma:

Kauri: daga 6mm zuwa 25mm

Siffa ta yau da kullun: farantin SISIC, bututun SISIC, SiSiC Hanyoyi uku, SISIC Elbow, SISIC Cone Cyclone.

Bayani: Akwai sauran girma da siffa akan buƙatun.

■Marufi:

A cikin akwatin kwali, cushe a cikin pallet ɗin katako mai ƙyalli tare da nauyin net ɗin 20-24MT/20′FCL.

■Babban fa'idodi:

1. Kyakkyawan juriya na lalacewa, juriya mai tasiri da juriya na lalata;

2. Excellent flatness da kyau kwarai zazzabi juriya har zuwa 1350 ℃

3. Sauƙi shigarwa;

4. Tsawon rayuwar sabis (yana kusan sau 7 fiye da na yumbu alumina da kuma sau 10 fiye da na

polyurethane

Samfurin tasirin kusurwa mai ƙanƙan daɗaɗɗen kusurwa

Lokacin da kwararar abin da ke lalata ya faɗo saman lalacewa a wani kusurwa mara zurfi ko ya wuce daidai da shi, nau'in lalacewa da ke faruwa a cikin juzu'i ana kiransa lalatar zamewa.

Babban yumbu na siliki na carbide yana ba da juriya da juriya da lalata yumbu da fale-falen rufi. An tabbatar da waɗannan samfuran lalacewa na kayan aiki a cikin isarwa, sarrafawa, da tsarin ajiya. Za a iya samar da fale-falen mu tare da kauri daga 8 zuwa 45mm. yana da mahimmanci don tabbatar da cewa zaku iya samun samfuran da ake buƙata. SiSiC: Taurin Moh shine 9.5 (New Moh's hardness shine 13), tare da kyakkyawan juriya ga yashwa da lalata, kyakkyawan abrasion - juriya da anti-oxidation. Yana da ƙarfi sau 4 zuwa 5 fiye da nitride bonded silicon carbide. Rayuwar sabis shine sau 5 zuwa 7 fiye da kayan alumina. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani dashi don ƙarin sifofi masu rikitarwa. Sawa yumbu mai juriya yana aiki don inganta aikin samarwa, dacewar aiki, rage farashin kulawa da karuwar riba.

Madaidaicin tukwane suna da ilimin kayan aiki, ƙwarewar aiki da ƙwarewar injiniya. Wannan zai iya yadda ya kamata tabbatar da cewa mafi kyau mafita suna miƙa wa abokan ciniki. Silicon carbide yumbura fale-falen buraka da rufi galibi ana amfani da su a aikace-aikace kamar guguwa, bututu, chutes, hoppers, bututu, bel na jigilar kaya da tsarin samarwa. A cikin tsarin, akwai abubuwa masu motsi suna zamewa a saman. Lokacin da abu ya zame akan wani abu, a hankali yana cire sassan har sai babu abin da ya rage. A cikin manyan wuraren lalacewa, wannan na iya faruwa akai-akai kuma yana haifar da matsaloli masu tsada. Babban tsarin yana riƙe ta hanyar amfani da abu mai wuyar gaske, kamar siliki carbide yumbura da alumina yumbu a matsayin rufin hadaya. A lokaci guda, yumbu na siliki na carbide na iya jurewa lalacewa kafin ya buƙaci maye gurbinsa, rayuwar sabis ɗin yumbu na siliki carbide shine sau 5 zuwa 7 fiye da kayan alumina.

Sawa Fale-falen yumbu na Silicon Carbide Juriya & Abubuwan Rufe:

Mai jure sinadarai

Wutar lantarki

Mechanical yashwa & abrasion resistant

Mai maye gurbinsa

Fa'idodin Fale-falen fale-falen fale-falen ƙera yumbu da rufi:

Ana iya amfani da shi a inda ake buƙatar juriya mai tsauri ko bakin ciki

Za a iya amfani da shi don sake farfado da wuraren da ake fama da lalacewa

Ana iya amfani da shi tare da hanyoyin haɗin kai da yawa kamar walda da adhesives

Musamman da aka ƙera don takamaiman aikace-aikace

Mai jure lalata

Maganin rage lalacewa mara nauyi

Yana kare sassa masu motsi waɗanda ke ƙarƙashin yanayin lalacewa

Mahimmanci wuce gona da iri & fin karfin rage lalacewa

Matsakaicin matsakaicin zafin amfani da ya kai 1380°C

Shandong Zhongpeng Special Ceramics Co., Ltd yana daya daga cikin manyan sabbin kayan yumbu na silicon carbide a cikin kasar Sin. SiC fasaha yumbura: Moh's taurin ne 9 (New Moh's taurin ne 13), tare da m juriya ga yashewa da lalata, m abrasion - juriya da anti-oxidation. Rayuwar sabis na samfurin SiC shine sau 4 zuwa 5 fiye da 92% na alumina. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani dashi don ƙarin sifofi masu rikitarwa. Tsarin zance yana da sauri, isarwa kamar yadda aka yi alkawari kuma ingancin ba shi da na biyu. Kullum muna dagewa wajen kalubalantar manufofinmu da mayar da zukatanmu ga al'umma.