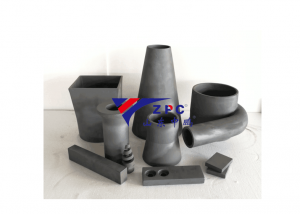

Silicon carbide FGD nozzles

Silicon carbide FGD nozzles sune mahimman abubuwan da ake buƙata na masana'antar wutar lantarki, manyan tukunyar jirgi, da desulphurization da na'urorin tattara ƙura.

Samfuran sun sami tagomashi da masana'antu daban-daban, saboda halayensu, kamar juriya na lalata, babban taurin, barga aiki da sauransu.

Ƙarƙashin Gas na Flue Gas (FGD) Nozzles

Cire sulfur oxides, wanda aka fi sani da SOx, daga iskar iskar gas ta amfani da reagent na alkali, kamar rigar farar ƙasa slurry.

Lokacin da aka yi amfani da burbushin mai a cikin hanyoyin konewa don sarrafa tukunyar jirgi, tanda, ko wasu kayan aiki suna da yuwuwar sakin SO2 ko SO3 a matsayin wani ɓangare na iskar gas. Wadannan sulfur oxides suna amsawa cikin sauƙi tare da wasu abubuwa don samar da fili mai cutarwa kamar sulfuric acid kuma suna da yuwuwar yin mummunan tasiri ga lafiyar ɗan adam da muhalli. Saboda waɗannan tasirin tasirin, sarrafa wannan fili a cikin iskar hayaƙi wani muhimmin sashi ne na masana'antar wutar lantarki da sauran aikace-aikacen masana'antu.

Sakamakon zaizayar ƙasa, toshewa, da haɓaka haɓakawa, ɗayan mafi amintattun tsarin sarrafa waɗannan hayaƙi shine tsarin buɗaɗɗen buɗaɗɗen buɗaɗɗen buɗaɗɗen buɗaɗɗen iskar gas (FGD) ta amfani da farar ƙasa, lemun tsami, ruwan teku, ko sauran maganin alkaline. Fesa nozzles suna iya yadda ya kamata kuma a dogara da su rarraba waɗannan slurries cikin hasumiya masu sha. Ta hanyar ƙirƙira nau'ikan nau'ikan ɗigon digo masu girma da kyau, waɗannan nozzles suna iya ƙirƙirar yanayin da ake buƙata yadda yakamata don shayarwa da kyau yayin da rage haɓakar maganin gogewa a cikin iskar hayaƙi.

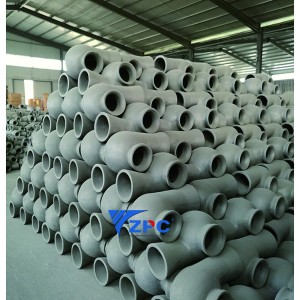

SiC FGD Absorber Nozzles:

A: Hollow Cone Tangential Nozzles

B: Cikakken Mazugi Tangential Nozzles

C: Cikakken Mazugi Sprial Nozzles

D: Nozzles

E: SMP Nozzles

Shandong Zhongpeng Special Ceramics Co., Ltd yana daya daga cikin manyan sabbin kayan yumbu na silicon carbide a cikin kasar Sin. SiC fasaha yumbura: Moh's taurin ne 9 (New Moh's taurin ne 13), tare da m juriya ga yashewa da lalata, m abrasion - juriya da anti-oxidation. Rayuwar sabis na samfurin SiC shine sau 4 zuwa 5 fiye da 92% kayan alumina. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani dashi don ƙarin sifofi masu rikitarwa. Tsarin zance yana da sauri, isarwa kamar yadda aka yi alkawari kuma ingancin ba shi da na biyu. Kullum muna dagewa wajen kalubalantar manufofinmu da mayar da zukatanmu ga al'umma.