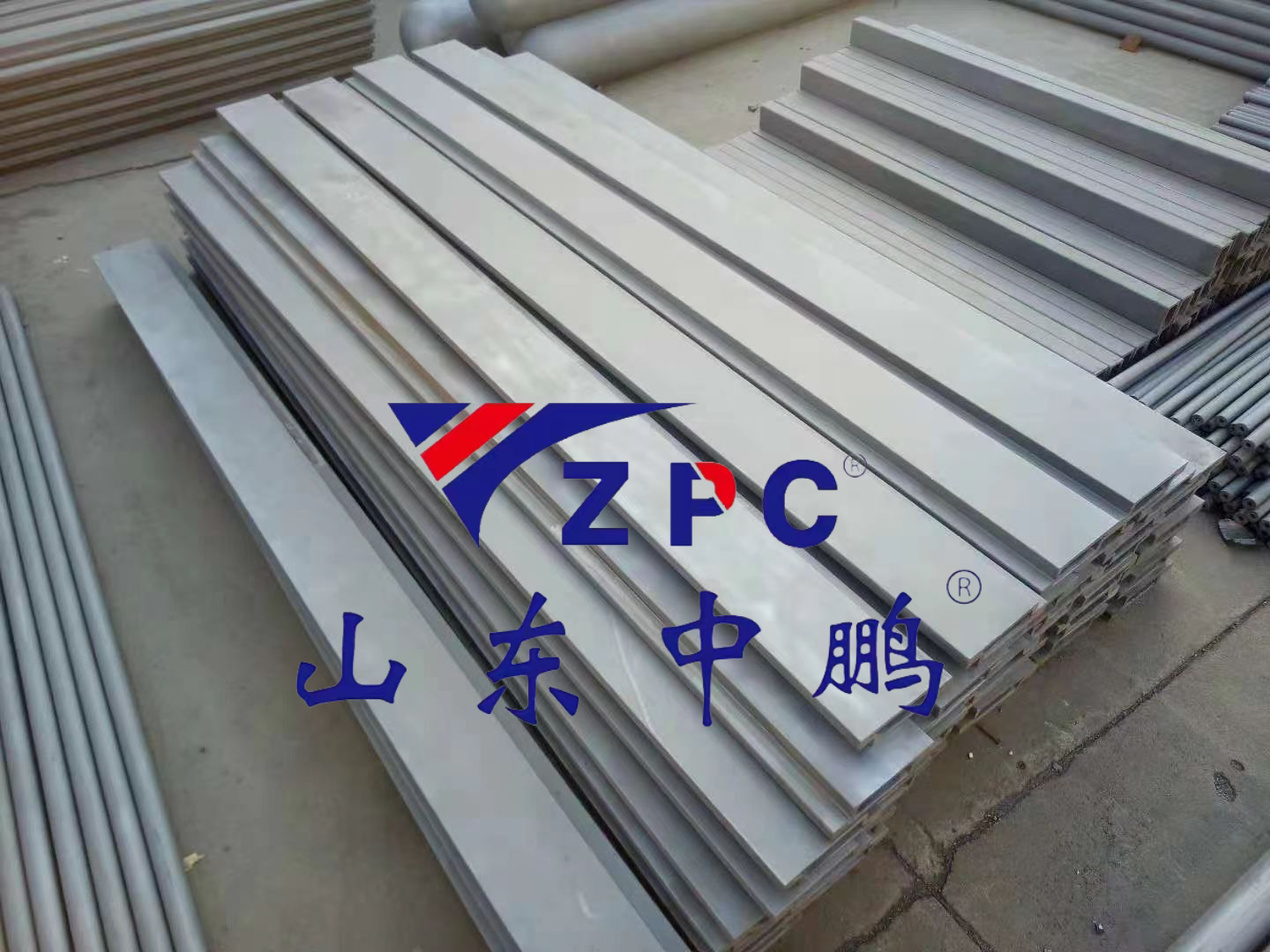

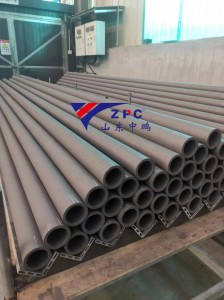

Silicon carbide katako

Silikon carbide (R-SiC) yumbu na yumbu mai amsawasun fito a matsayin mahimmin abubuwa masu mahimmanci a cikin tsarin sarrafa zafi na zamani, musamman ƙware a masana'antar batirin lithium, samar da yumbu na ci gaba, da madaidaicin kayan maganadisu. Waɗannan na'urori na musamman suna sake fasalta ƙa'idodin aiki a cikin tanderun masana'antu masu zafi ta hanyar magance manyan ƙalubale a cikin kwanciyar hankali da ƙarfin injina.

Ayyukan Thermal Mara Daidaitawa

An ƙera shi don ci gaba da aiki a 1450-1600 ° C - mahimmanci mafi girma fiye da nadiyoyin alumina na gargajiya - R-SiC rollers suna kula da daidaiton ma'auni ko da a ƙarƙashin matsanancin hawan keke. Keɓaɓɓen tsarin su yana ba da damar:

• Daidaitawar canja wurin zafi cikin sauri (±5°C fadin tsayin abin nadi)

• Jurewa 100+ thermal shock cycles (1400°C ↔ dakin zafin jiki)

Nakasar sifili a yanayin zafi mai tsayi

An Sake Fayyace Mahimman Aikace-aikace

1. Samar da Batirin Lithium

- Madaidaicin jeri don sintirin kayan lantarki

- Kiyayewa mara lahani na NMC/LFP cathodes

- Tsayayyen aiki a cikin rage yanayi

2. Advanced Ceramics Processing

- Tallafin kyauta don manyan fale-falen fale-falen buraka (har zuwa 1.5 × 3m)

- Daidaitaccen sarrafa saurin gudu a cikin layin glazing sanitaryware

- Ƙarshen ƙasa mara alama (Ra <0.8μm)

3. Magnetic Material Manufacturing

- Juyawa mara girgiza don madaidaicin ferrite sintering

- Rashin rashin aikin sinadari a cikin mahalli masu wadatar hydrogen

Amfanin Aiki

Ƙarfin Load: Yana goyan bayan 3-5× mafi girman nauyi a kowane tsayin raka'a vs. ƙarfe gami rollers

Resistance Deformation: Yana kiyaye <0.05mm/m madaidaiciya bayan sa'o'in aiki 10,000

Amfanin Makamashi: 18-22% rage yawan amfani da wutar lantarki ta hanyar ingantaccen rarraba zafi

Daidaituwar Masana'antu: Mai daidaitawa ga kilns na jigilar kaya, murhu mai dumbin dumbin nadi, da tanderun tunnel ɗin matasan.

Dorewar Tattalin Arziki

Yayin da ake buƙatar 30-40% mafi girman saka hannun jari na farko fiye da rollers na al'ada, hanyoyin R-SiC suna nuna:

- 70% tsayin tazarar sabis (shekaru 5-7 vs. 2-3 shekaru)

- 90% sake yin amfani da su ta hanyar hanyoyin sake fasalin thermal

- 60% ƙananan farashin kulawa daga filaye masu jurewa

Zane-Shirya Gaba

Na zamani R-SiC rollers yanzu sun haɗa:

- Laser-saƙaƙƙarfan ragi na bin diddigin layukan samarwa na atomatik

- Porosity na musamman don ƙayyadaddun yanayin yanayi

- Haɗaɗɗen na'urori masu auna zafin jiki don ayyukan kiln mai kaifin baki

Wadannan fasaha ci gaban matsayi dauki-sintered silicon carbide rollers a matsayin makawa aka gyara a gaba-tsara masana'antu dumama tsarin, kunna masana'antun don cimma tighter zafin jiki iko, mafi girma samfurin daidaito, da kuma ci gaba samar workflows fadin mahara high-tech sassa.

Shandong Zhongpeng Special Ceramics Co., Ltd yana daya daga cikin manyan sabbin kayan yumbu na silicon carbide a cikin kasar Sin. SiC fasaha yumbura: Moh's taurin ne 9 (New Moh's taurin ne 13), tare da m juriya ga yashewa da lalata, m abrasion - juriya da anti-oxidation. Rayuwar sabis na samfurin SiC shine sau 4 zuwa 5 fiye da 92% na alumina. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani dashi don ƙarin sifofi masu rikitarwa. Tsarin zance yana da sauri, isarwa kamar yadda aka yi alkawari kuma ingancin ba shi da na biyu. Kullum muna dagewa wajen kalubalantar manufofinmu da mayar da zukatanmu ga al'umma.