Farashin SiC

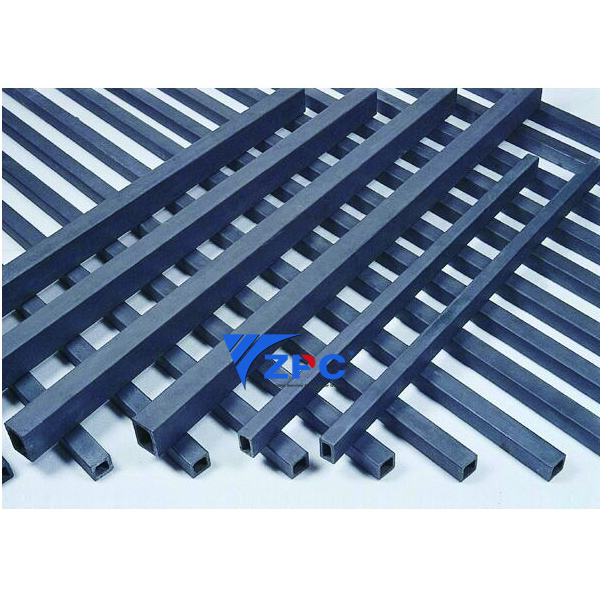

Reaction Bonded Silicon Carbide Babban ƙarfi Babban Madaidaicin Sisic / Rbsic Rollers da Biams

Reaction sintering silicon carbide yumbu nadi ne yafi amfani ga lithium baturi masana'antu, yau da kullum ain, sanitary ain, gini yumbu da Magnetic kayan, kamar nadi kiln, high zafin jiki kona tare da manufa kiln, tare da dogon sabis rayuwa. Yana da babban zafin jiki ƙarfi, thermal girgiza juriya, high zafin jiki creep juriya, karfi juriya, mai kyau lalacewa juriya.

Ana amfani da kulake don yau da kullun - yumbu da aka yi amfani da su, yumbun tsafta, yumbun gini, kayan Magnetic da yankin zafin wuta na abin nadi.

| Silicon Carbide Ƙayyadaddun Samfura: | ||||

| Abu | Naúrar | Farashin SSIC | RBSIC SISIC | R-SIC |

| Tsafta | (%) | ≥ 99 | ≥90% | ≥ 99 |

| zafin aikace-aikace | ºC | 1700 | 1380 | 1650 |

| Yawan yawa | g/CM2 | ≥3.10-3.15 | ≥3.02 | 2.65-2.75 |

| Bude porosity | % | ≤0.1 | ≤0.1 | |

| Tauri | ≥92 HRA | 2400 Kg/mm2 | 1800-2000 Kg/mm2 | |

| Karfin lankwasawa | MPa | 400-580 | 250 (20ºC) | ≥300 |

| 281 (1200ºC) | ||||

| Ƙarfin ƙarfi | Mpa | ≥200 | ≥190 | |

| modules na elasticity | GPA | 400 | 332(20ºC) | 80-100 (20ºC) |

| 300 (1200ºC) | 90-110 (1200ºC) | |||

| Thermal Conductivity | W/mk | 100-120 | 45 (1200ºC) | 36 |

| Coefficient na thermal fadadawa | K1X106 | 4.2 | 4.5 | 4.6 |

| Tsauri | Gpa | >25 | 13 | |

| Acid&Ikali juriya | Madalla | Madalla | Madalla | |

| SiC Takaddun Samfura: | ||||

| Abu | Naúrar | OC-1 | OC-2 | MC-3 |

| SiC | (%) | ≥90 | ≥86 | ≥80 |

| Bayyanar Porosity | (%) | ≤10 | ≤13 | ≤16 |

| Yawan yawa | g/CM2 | ≥2.66 | ≥2.63 | ≥2.6 |

| zafin aikace-aikace | ºC | ≥1680 | ≥1620 | ≥1550 |

| Coefficient na thermal fadadawa | aX 10-6/ºC | ≤4.8 | ≤5.0 | ≤5.5 |

| Karfin Lankwasa | 1200ºC | ≥45 | ≥40 | ≥30 |

Shandong Zhongpeng Special Ceramics Co., Ltd yana daya daga cikin manyan sabbin kayan yumbu na silicon carbide a cikin kasar Sin. SiC fasaha yumbura: Moh's taurin ne 9 (New Moh's taurin ne 13), tare da m juriya ga yashewa da lalata, m abrasion - juriya da anti-oxidation. Rayuwar sabis na samfurin SiC shine sau 4 zuwa 5 fiye da 92% na alumina. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani dashi don ƙarin sifofi masu rikitarwa. Tsarin zance yana da sauri, isarwa kamar yadda aka yi alkawari kuma ingancin ba shi da na biyu. Kullum muna dagewa wajen kalubalantar manufofinmu da mayar da zukatanmu ga al'umma.