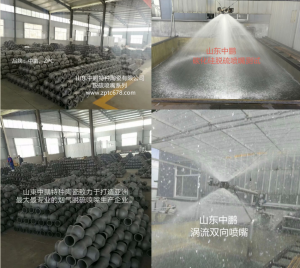

FGD Silicon carbide spray nozzles

RUWAN GASKIYAR RUWAN RUWAN GAS TARE DA WUTA

Kayayyakinmu suna da tsawon rayuwar sabis, wanda yayi daidai da shahararrun samfuran duniya: SPRAY, BETE, LECHLER.

Siffofin

Za'a iya samun ingantaccen aikin desulphurisation sama da 99%

Samuwar sama da kashi 98% na iya samuwa

Injiniya bai dogara da kowane takamaiman wuri ba

Samfurin kasuwa

Unlimited part load aiki

Hanya tare da mafi girman adadin nassoshi a duniya

| Dukiya | Daraja |

|---|---|

| Yawan yawa (kg.m-3) | 3030 |

| Bayyanar Ƙarfi (%) | 0 |

| Modul na Matasa (GPa) | 400 |

| Ƙarfin Lanƙwasa (MPa) | 390 |

| Hardness (VHN) | 2500 |

| Ƙididdigar Ƙarfafa Ƙwararru (x 10-6/ºC) | 4.3 |

| Ƙarfafa Ƙarfafawa (W/mK) | 145 |

| Matsakaicin zafin amfani (ºC) | 1375 |

Tsaftace iskar hayaki ta hanyar dakatar da lemun tsami

Ga rigar desulphurisation na flue gas, an wuce ta cikin abin sha (scrubber). Dakatar da lemun tsami da aka bayar a cikin abin sha (madarar farar ƙasa ko madarar lemun tsami) tana amsawa da sulfur dioxide daga iskar hayaƙi. Mafi kyawun canja wurin taro, mafi inganci desulphurisation shine.

A lokaci guda tare da sha, iskar hayaki yana cike da tururin ruwa. Ana fitar da abin da ake kira "tsabta gas" ta hanyar jikakken bututun hayaki ko hasumiya mai sanyaya. Ruwan da aka rasa don aikin dole ne a maye gurbinsa. Lemun tsami slurry da aka zuga a wurare dabam dabam ana kiyaye shi ta hanyar sinadarai ta hanyar shayar da madaidaicin juzu'i da maye gurbinsa da sabon dakatarwa. Ruwan ɓangaren da aka zubar ya ƙunshi gypsum, wanda - sauƙaƙa - samfurin amsawa ne na lemun tsami da sulfur kuma za'a iya siyar da shi bayan shafe ruwa (misali ga ganuwar gypsum a cikin masana'antar gini).

Ana amfani da nozzles na yumbu na musamman don allurar dakatarwar lemun tsami a cikin abin sha. Wadannan nozzles suna samar da ƙananan ɗigon ruwa da yawa daga dakatarwar da aka yi amfani da su kuma don haka babban abin da ya dace daidai da shi don canja wurin taro mai kyau. Kayan yumbu yana ba da izinin rayuwa mai tsawo duk da cewa dakatarwar lemun tsami tare da abun ciki na gypsum yana da kaddarorin abrasive. A cikin zane mun haɗa mahimmancin mahimmanci ga sassan giciye na kyauta, don haka ƙananan ƙazanta a cikin dakatarwa ba za su iya saita nozzles ba. Don aiki na tattalin arziki, waɗannan nozzles za a iya daidaita su zuwa mafi girman kewayon inganci na famfo. Ana iya ƙayyade bututun ƙarfe don (kusan) kowane ƙalubalen injiniyan tsari. Baya ga cikkaken mazugi da bututun mazugi a cikin kusurwoyi daban-daban na fesa da adadin kwararar ruwa, bututun bututun na ZPC tare da diyya mai haƙƙin mallaka yana kuma samuwa.

Yankin shayarwa ya ƙunshi matakan nozzles da yawa da tsarin rarraba digo a kwance a kwance, don dawo da ɗigon ɗigo mai kyau da aka ɗauka tare da rafin iskar gas zuwa tsari. Tare da mu high yi droplet separators za ka iya ƙara yadda ya dace da shuka.

Daskararrun da ke cikin dakatarwa na iya haifar da adibas, misali a cikin mai raba droplet, a cikin bututun shiga ko a kan bututu, wanda zai haifar da matsaloli a cikin aiki. Tun da ko da yaushe ana janye ruwa daga kewaye ta hanyar ƙaura, dole ne a ciyar da ruwa a cikin abin sha, wanda zai iya kuma ya kamata a yi amfani dashi don tsaftacewa. Nozzles harshen ZPC sun tabbatar da kansu don tsaftace mashigar hayaƙin hayaƙi. Ana amfani da cikakken bututun mazugi na ZPC don tsaftace masu rarraba droplet.

Ana amfani da robobi (misali na bututun mai) da roba (misali gaskets, rufin roba, da sauransu) a cikin na'ura mai ɗaukar hoto wanda juriyar zafinsa ya yi ƙasa da zafin iskar gas mara sanyi. A al'ada, dakatarwar da aka kunna a cikin da'ira yana kwantar da iskar gas mai kyau, amma idan, alal misali, an dakatar da famfon ciyarwa, za a iya lalata robobi da robar. Ƙananan nozzles na ƙarfe na musamman-gawa sun tabbatar da ƙimar su a nan, waɗanda ke ɗaukar sanyaya a wannan lokacin kuma don haka suna kare saka hannun jari na masana'antar sarrafa iskar gas.

Reaction bonded silicon carbide (SiSiC): Taurin Moh shine 9.2, tare da kyakkyawan juriya ga yashwa da lalata, kyakkyawan juriya-juriya da anti-oxidation. Yana da ƙarfi sau 4 zuwa 5 fiye da nitride bonded silicon carbide. Rayuwar sabis shine sau 7 zuwa 10 fiye da kayan alumina. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani dashi don ƙarin sifofi masu rikitarwa.

Shandong Zhongpeng Special Ceramics Co., Ltd yana daya daga cikin manyan sabbin kayan yumbu na silicon carbide a cikin kasar Sin. SiC fasaha yumbura: Moh's taurin ne 9 (New Moh's taurin ne 13), tare da m juriya ga yashewa da lalata, m abrasion - juriya da anti-oxidation. Rayuwar sabis na samfurin SiC shine sau 4 zuwa 5 fiye da 92% kayan alumina. MOR na RBSiC shine sau 5 zuwa 7 na SNBSC, ana iya amfani dashi don ƙarin sifofi masu rikitarwa. Tsarin zance yana da sauri, isarwa kamar yadda aka yi alkawari kuma ingancin ba shi da na biyu. Kullum muna dagewa wajen kalubalantar manufofinmu da mayar da zukatanmu ga al'umma.