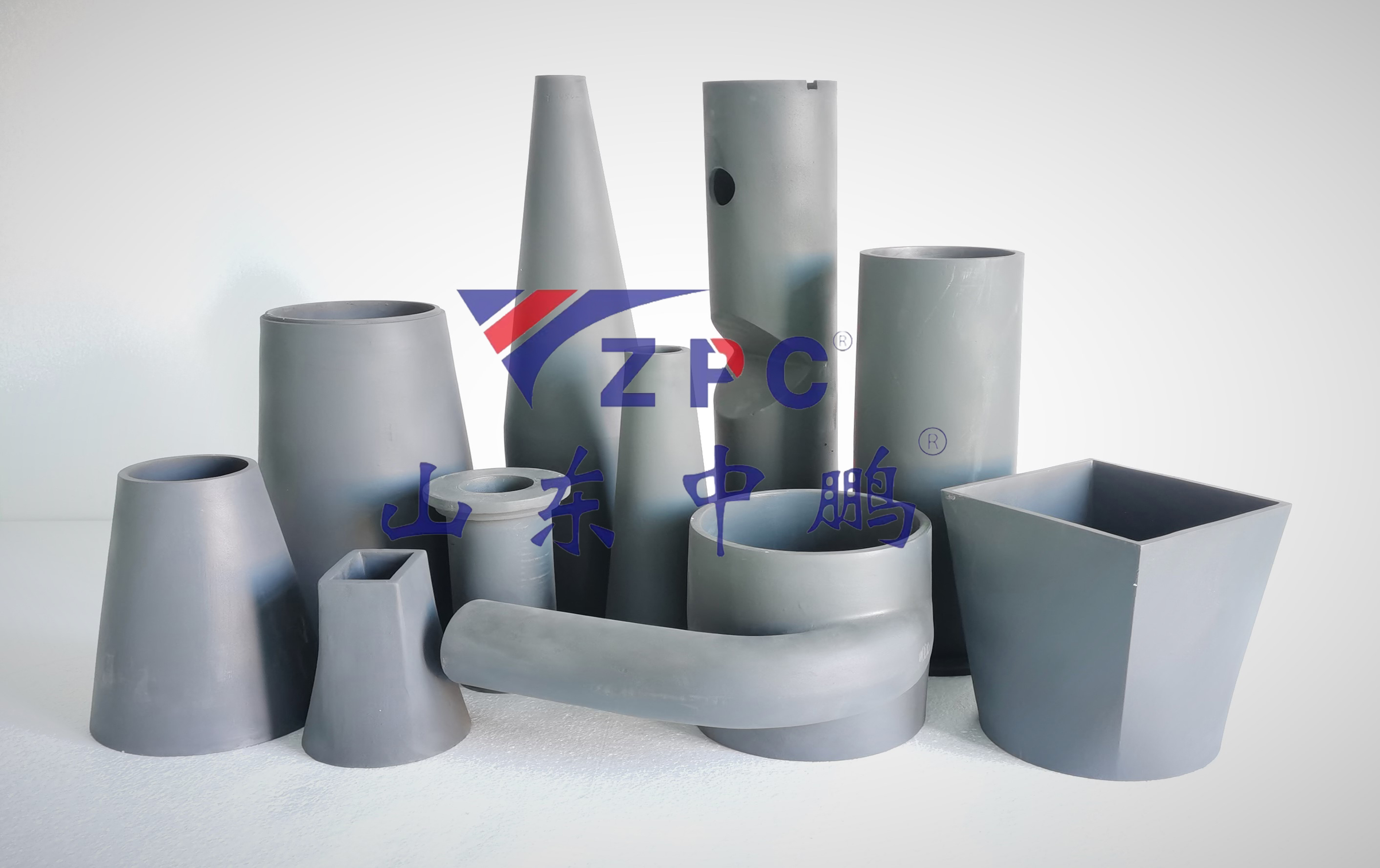

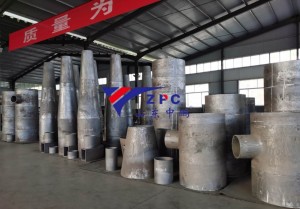

I-silicon carbide ceramic liners

I-silicon carbide-resistant-resistant lining

Izici Zokuklama Ze-Silicon Carbide (SiC) I-Wear-Resistant Liners:

(1) Idizayini Yendlela Yokugeleza Elula

Ikhontayutha ebushelelezi, ehlelekile ukusuka endaweni yokungena kuye endaweni ephumayo inciphisa ukumelana nokugeleza, okwenza amalayini e-SiC avumelane nezimo ezihlukahlukene zokusebenza kwezimboni.

(2) I-Atomization ethuthukisiwe

I-MechanismLiquids yenziwa i-athomu ibe amaconsi amahle ngokungqubuzana okuqinile ngokuncipha kancane kancane kwezindawo ze-helical ze-SiC liner, okuqinisekisa ukusatshalaliswa kwesifutho esifanayo.

(3) Isakhiwo Esiqinile, Esingenasici

Ishaneli yokugeleza eqondile, engena-coreless iqeda izithiyo zangaphakathi, ikhulise ukuphuma koketshezi ngaphakathi kobukhulu bamapayipi avalelwe kuyilapho ivimbela ukuvinjwa.

(4) Izindlela Zokufutha Ezikabili Zokusebenza Okuthuthukisiwe

Isekela kokubili amaphethini okufutha wekhoni eqinile kanye ne-hollow-cone, enikeza ama-engeli okukhava abanzi kanye nokusebenza okuvimbela ukuvala imisebenzi esebenza kahle kakhulu.

Izinzuzo eziyinhloko uma ziqhathaniswa nezinye izinto:

(1) I-Wear Resistance

Ukuqina: Amalayini e-SiC afinyelela ubulukhuni be-Mohs obungu-9.5 (vs. 8.0 kumaceramics e-alumina, 6.0 ngensimbi ye-chromium ephezulu), okubenza bakwazi ukumelana nokuguga okwedlulele kuma-slurries asezimayini, umlotha wamalahle, nezimpushana zensimbi.

Ubude besikhathi: Impilo yesevisi idlula 5–10× izinto zendabuko (isb. irabha noma amalayini e-polyurethane) ezintweni ezithinta kakhulu ezifana nezigayo zamabhola noma amaphampu anodaka.

(2) Ukugqwala kanye Nokungangeni Kwamakhemikhali

Ukumelana ne-Acid/Alkali:Imelana ne-sulfuric acid egxilile (98%), i-sodium hydroxide (50%), nosawoti oncibilikisiwe (isb. i-NaCl-KCl ku-800°C), kuyilapho izinsimbi zigqwala ngokushesha futhi ama-polymer wonakala.

I-Zero Ukungcoliswa: Indawo engasasebenzi iqinisekisa ubumsulwa ku-semiconductor noma ukukhiqizwa kwebhethri ye-lithium, ngokungafani namalayini ensimbi athambekele ekungeneni kwe-ion.

(3) Ukuzinza Kwezinga Lokushisa Kakhulu

I-Thermal Resilience:Isebenza ngokuqhubekayo ku-1,600°C (uma iqhathaniswa nomkhawulo we-alumina's 1,200°C) ngokunwebeka okuncane kokushisa (CTE: 4.0×10⁻⁶/℃), ivimbela ukuqhekeka kooko noma kwiziko elincibilikayo.

I-Thermal Shock Resistance:Igcina ubuqotho besakhiwo ngaphansi kokushintshashintsha kwezinga lokushisa okusheshayo (isb. ukucisha ukusuka ku-1,000°C kuya kuzinga lokushisa legumbi), ngokungafani nezitsha zobumba eziphukayo.

(4)Energy Efficiency and Lightweight Design

I-Low Friction: Indawo ye-SiC epholishiwe (i-Ra <0.1 μm) yehlisa ukumelana noketshezi ngo-30–50% uma iqhathaniswa namalayini ensimbi amaholoholo, ukunqamula izindleko zamandla okupompa.

Ukonga Isisindo:Ukuminyana okungu-3.1 g/cm³ (vs. kwensimbi 7.8 g/cm³) kwenza ukufakwa kalula futhi kusekele okokusebenza okungasindi ku-aerospace noma amayunithi okucubungula amaselula.

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingesinye sezixazululo ezintsha ze-silicon carbide zobumba eChina. I-ceramic yobuchwepheshe ye-SiC: Ubulukhuni be-Moh buyi-9 (ukuqina kwe-Moh entsha yi-13), enokumelana okuhle nokuguguleka nokugqwala, ukuhuzuka okuhle kakhulu – ukumelana ne-oxidation. Impilo yesevisi yomkhiqizo we-SiC iyinde izikhathi ezi-4 kuya kwezi-5 kune-alumina material engu-92%. I-MOR ye-RBSiC izikhathi ezi-5 kuye kweziyi-7 kune-SNBSC, ingasetshenziselwa izimo eziyinkimbinkimbi. Inqubo yekhotheshini iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ingeyesibili. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisele izinhliziyo zethu emphakathini.