Ipayipi le-silicon carbide ceramic lined ne-hydrocyclone ezitshalweni zamandla

I-Silicon Carbide Ceramic Piping Systems: Ukusungula kabusha Ingqalasizinda Yesikhungo Samandla

Izikhungo zokuphehla ugesi zibhekene nezinselelo ezidlulele zokusebenza, nezinhlelo zamapayipi ezihlala njalo:

- Ukuhamba ngebhayisikili okushisayo okuqhubekayo (100–650°C)

- Isivinini sezinhlayiyana eziqhumayo ezingaphezu kuka-30 m/s

- ukuhluka kwe-pH kusuka ku-2-12 ku-flue gas scrubbers

- Ukushintshashintsha kwe-cyclic pressure (0–6 MPa)

Amapayipi ensimbi endabuko nawe-polymer avame ukuhluleka ngaphansi kwalezi zimo, okwenza amapayipi e-silicon carbide (SiC) e-ceramic angagugi abe yisixazululo esinobunjiniyela sezitshalo zamandla zanamuhla.

Ukuphumelela Kwesayensi Yezinto Ezibalulekile

Amapayipi e-ceramic e-SiC ahlanganisa izakhiwo eziyingqayizivele ezibalulekile ekusetshenzisweni komkhakha wamandla:

- I-Vickers Hardness 28 GPa (4× inzima kune-tungsten carbide)

- Izinga Lokugqoka <0.1 mm³/N·m (ASTM G65)

- I-Thermal Conductivity 120 W/m·K (iphezulu kunensimbi engagqwali)

- Ukungangeni Kwamakhemikhali (kumelana no-98% H₂SO₄ ku-300°C)

Izinzuzo Zokusebenza Ezinhlelweni Ezibucayi

1. Ukuphatha Amalahle Nokuthutha Umlotha

- Ukumelana nokuguga okungama-5–7 mm/unyaka kusuka ku-60% we-solid-content slurry

- Gcina ukuncishiswa kokugeleza okungu-<5% ngaphezu kwamahora okusebenza angu-10,000

2. I-Flue Gas Desulfurization (FGD)

- Ukusebenza ukumelana ne-pH kumasekhethi we-limestone slurry

- Susa ukugqwala kwe-pitting eyenziwe nge-chloride

3. I-Fly Ash Conveyance

- 0.08 μm ubulukhuni bobuso bunciphisa ukunamathela kwezinhlayiyana

- Bamba umthamo we-50 tph kuma-engeli wokuthambekela angama-35°

Uguquko Kwezomnotho

Abasebenzi bezitshalo babika izinzuzo ezilinganisekayo:

- Ukwehliswa ngo-70% kokushintshwa kwamapayipi okungahleliwe

- 55% izindleko zesondlo eziphansi

- U-18% uthuthukise ukusebenza kahle kokushisa emijikelezweni yesitimu

- 40% wesikhathi sesistimu enwetshiwe uma kuqhathaniswa nezinye izinhlobo zengxubevange

Ukufakwa Nokuguquguquka Kokusebenza

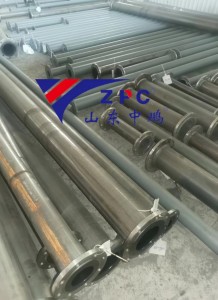

- Izingxenye ze-modular 1–6 m ezinoxhumo olunezinhlangothi/ezinemicu

- 60% ukwehlisa isisindo uma kuqhathaniswa nokulingana kwensimbi (3.2 g/cm³ ukuminyana)

- Ingabuyiselwa ezisekelweni zamapayipi ezikhona nama-hangers

- Ihambisana nezinhlelo zokuqapha ezihlakaniphile zokubikezela ukugqokwa

Izindlela Ezintsha Ezigxile Kwikusasa

Izixazululo zepayipi ze-SiC zesizukulwane esilandelayo ziyahlanganisa:

- I-Gradient porosity yokunciphisa ukucindezeleka okushisayo

- Izinhlobonhlobo ze-conductive zemvula ye-electrostatic

- Amajoyinti e-ceramic-elastomer ayinhlanganisela yokudambisa ukudlidliza

- I-self-cleaner surface nano-textures

Kusukela ezitshalweni ezibaselwa ngamalahle kuya ezikhungweni zokulahla imfucuza kuya kumandla, amapayipi e-silicon carbide ceramic achaza kabusha ukwethembeka kwingqalasizinda yamandla. Inhlanganisela yabo eyingqayizivele yokuqina kwemishini, ukukhuthazela kokushisa, nokuzinza kwamakhemikhali kuqinisekisa ukusebenza okuqhubekayo ngaphansi kwezimo ezimbi kakhulu - ukuguqula amashejuli okulungisa kusukela ekulungiseni okusebenzayo kuya ekuthuthukisweni okuhleliwe, okungabizi kakhulu.

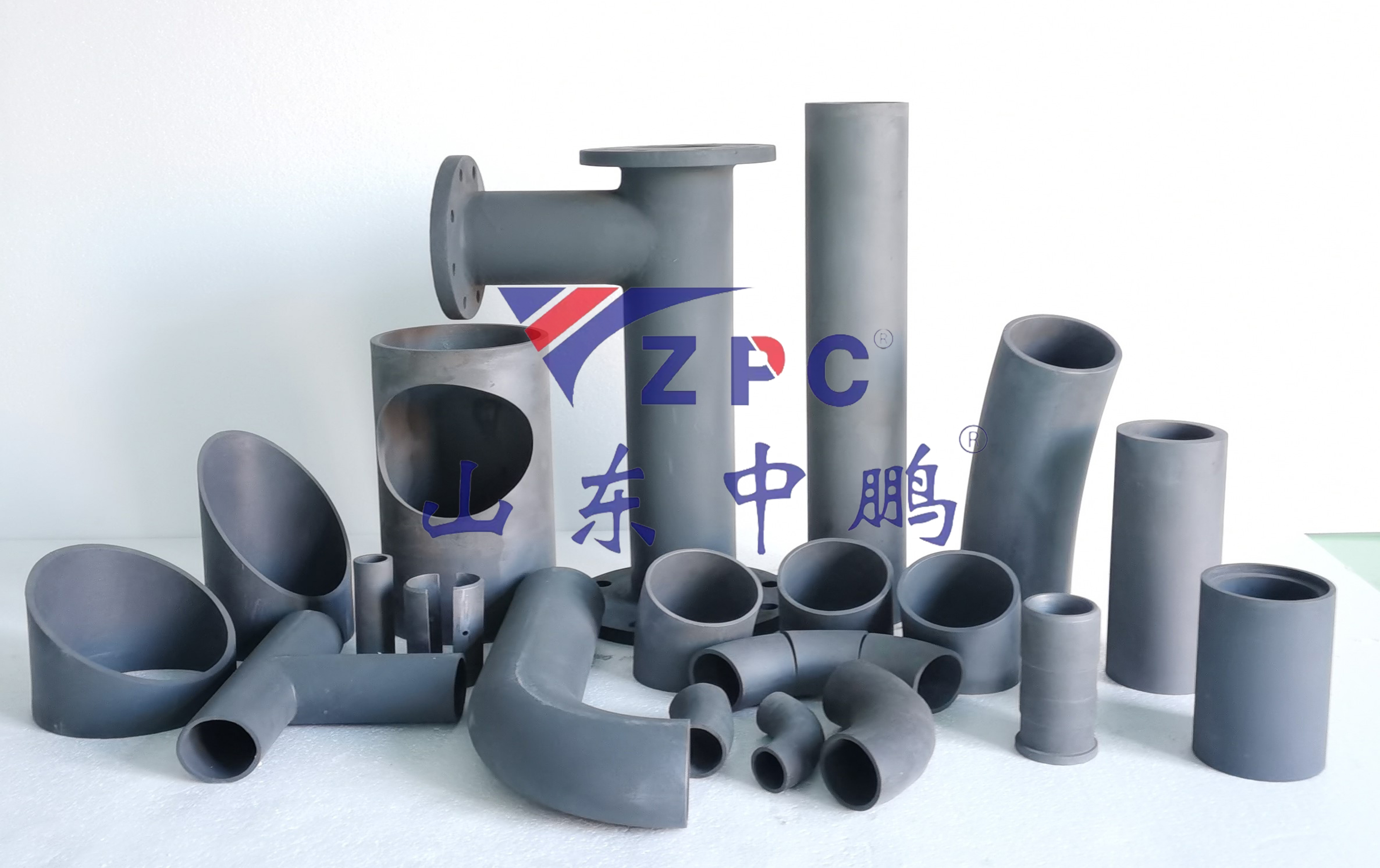

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingesinye sezixazululo ezintsha ze-silicon carbide zobumba eChina. I-ceramic yobuchwepheshe ye-SiC: Ubulukhuni be-Moh buyi-9 (ukuqina kwe-Moh entsha yi-13), enokumelana okuhle nokuguguleka nokugqwala, ukuhuzuka okuhle kakhulu – ukumelana ne-oxidation. Impilo yesevisi yomkhiqizo we-SiC iyinde izikhathi ezi-4 kuya kwezi-5 kune-alumina material engu-92%. I-MOR ye-RBSiC izikhathi ezi-5 kuye kweziyi-7 kune-SNBSC, ingasetshenziselwa izimo eziyinkimbinkimbi. Inqubo yekhotheshini iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ingeyesibili. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisele izinhliziyo zethu emphakathini.