Imishayo ye-silicon carbide

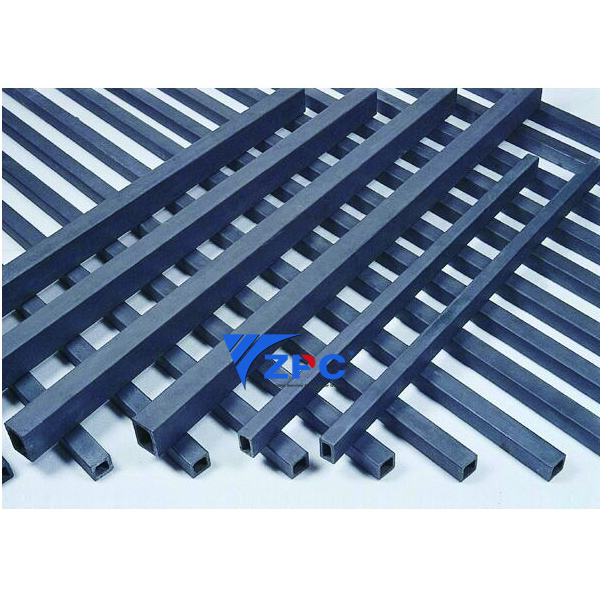

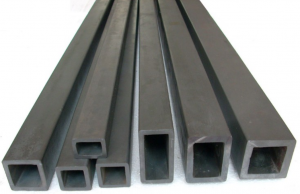

I-Reaction Bonded Silicon Carbide High Strength High Straightness Sisic/ Rbsic Rollers kanye nemishayo

I-Reaction sintering silicon carbide ceramics roller isetshenziswa kakhulu embonini yebhethri ye-lithium, i-porcelain yansuku zonke, i-porcelain ye-sanitary, izitsha zobumba zokwakha kanye nezinto zikazibuthe, ezifana ne-roller kiln, izinga lokushisa eliphezulu elivuthayo elineziko elifanele, elinempilo ende yesevisi. Inamandla okushisa aphezulu, ukumelana nokushisa okushisayo, ukumelana nokushisa okuphezulu kokushisa, ukumelana okuqinile, ukumelana okuhle kokugqoka.

Amakilabhu asebenza nsuku zonke - izitsha zobumba ezisetshenziswayo, i-porcelain ye-sanitary, i-Ceramic Building, i-Magnetic material kanye nendawo yokushisa ephezulu yokushisa ye-roller kiln.

| Ukucaciswa komkhiqizo we-Silicon Carbide: | ||||

| Into | Iyunithi | I-SSIC | I-RBSIC SISIC | I-R-SIC |

| Ubumsulwa | ( %) | ≥99 | ≥90% | ≥99 |

| Izinga lokushisa lohlelo lokusebenza | ºC | 1700 | 1380 | 1650 |

| Ukuminyana | g/CM2 | ≥3.10-3.15 | ≥3.02 | 2.65-2.75 |

| I-porosity evulekile | % | ≤0.1 | ≤0.1 | |

| Ukuqina | ≥92 HRA | 2400 Kg/mm2 | 1800-2000 Kg/mm2 | |

| Amandla okugoba | I-MPa | 400-580 | 250(20ºC) | ≥300 |

| 281(1200ºC) | ||||

| Amandla aqinile | Mpa | ≥200 | ≥190 | |

| I-modulus ye-elasticity | I-GPa | 400 | 332(20ºC) | 80-100(20ºC) |

| 300(1200ºC) | 90-110(1200ºC) | |||

| I-Thermal Conductivity | W/mk | 100-120 | 45(1200ºC) | 36 |

| I-coefficient yokwanda kwe-thermal | K1X 106 | 4.2 | 4.5 | 4.6 |

| Ukuqina | I-Gpa | >25 | 13 | |

| Ukumelana ne-Acid & Ikali | Kuhle kakhulu | Kuhle kakhulu | Kuhle kakhulu | |

| Ukucaciswa komkhiqizo we-SiC: | ||||

| Into | Iyunithi | OC-1 | OC-2 | MC-3 |

| I-SiC | (%) | ≥90 | ≥86 | ≥80 |

| I-Porosity ebonakalayo | (%) | ≤10 | ≤13 | ≤16 |

| Ukuminyana | g/CM2 | ≥2.66 | ≥2.63 | ≥2.6 |

| Izinga lokushisa lohlelo lokusebenza | ºC | ≥1680 | ≥1620 | ≥1550 |

| I-coefficient yokwanda kwe-thermal | i-aX 10-6/ºC | ≤4.8 | ≤5.0 | ≤5.5 |

| Ukugoba Amandla | 1200ºC | ≥45 | ≥40 | ≥30 |

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingesinye sezixazululo ezintsha ze-silicon carbide zobumba eChina. I-ceramic yobuchwepheshe ye-SiC: Ubulukhuni be-Moh buyi-9 (ukuqina kwe-Moh entsha yi-13), enokumelana okuhle nokuguguleka nokugqwala, ukuhuzuka okuhle kakhulu – ukumelana ne-oxidation. Impilo yesevisi yomkhiqizo we-SiC iyinde izikhathi ezi-4 kuya kwezi-5 kune-alumina material engu-92%. I-MOR ye-RBSiC izikhathi ezi-5 kuye kweziyi-7 kune-SNBSC, ingasetshenziselwa izimo eziyinkimbinkimbi. Inqubo yekhotheshini iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ingeyesibili. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisele izinhliziyo zethu emphakathini.