Imishayo ye-silicon carbide

Amarola e-ceramic e-Reaction-sintered silicon carbide (R-SiC).ziye zavela njengezingxenye ezibalulekile ezinhlelweni zesimanje zokucubungula okushisayo, ikakhulukazi eziphuma phambili ekwenziweni kwebhethri ye-lithium, ukukhiqizwa kwe-ceramics okuthuthukisiwe, kanye nokunemba kwezinto ezibonakalayo zikazibuthe. Lawa ma-roller akhethekile achaza kabusha amazinga okusebenza eziko ezimbonini ezinezinga lokushisa eliphezulu ngokubhekana nezinselelo ezibalulekile ekuzinzeni kwezinga lokushisa nokuqina kwemishini.

Ukusebenza Okushisayo Okungafani

Idizayinelwe ukuthi isebenze ngokuqhubekayo ku-1450-1600°C - iphakeme kakhulu kunamarola e-alumina endabuko - amarola e-R-SiC agcina ukunemba kobukhulu ngisho nangaphansi kokuhamba ngebhayisikili okushisayo. I-microstructure yabo ehlukile inika amandla:

• Ukufana kokudlulisa ukushisa okusheshayo (±5°C kubo bonke ubude berola)

• Ukumelana nemijikelezo yokushisa engu-100+ (1400°C ↔ izinga lokushisa legumbi)

• I-Zero creep deformation emazingeni okushisa aqhubekayo

Izicelo Ezibucayi Zichazwe Kabusha

1. Ukukhiqizwa Kwebhethri ye-Lithium

- Ukuqondanisa okunembile kwe-electrode material sintering

- Ukuphathwa okungangcoliswanga kwama-cathodes e-NMC/LFP

- Ukusebenza okuzinzile ekunciphiseni umkhathi

2. I-Advanced Ceramics Processing

- Ukusekelwa kwe-Warp-free kwamathayela anefomethi enkulu (kufika ku-1.5×3m)

- Ukulawulwa kwejubane okungaguquki emigqeni ecwebezelayo ye-sanitaryware

- Indawo engaphawuli ukuphela (Ra <0.8μm)

3. Ukukhiqizwa Kwezinto Ezizibuthe

- Ukuzungezisa okungadlidlizi kwe-ferrite sintering

- Ukungena kwamakhemikhali ezindaweni ezinothe nge-hydrogen

Izinzuzo Zokusebenza

Umthamo Womthwalo: Isekela 3-5× isisindo esikhulu ngobude beyunithi ngayinye uma iqhathaniswa namarola engxubevange yensimbi

I-Deformation Resistance: Igcina u-<0.05mm/m oqondile ngemva kwamahora okusebenza angu-10,000

Ukusebenza Kwamandla:18-22% yehlise ukusetshenziswa kwamandla esithandweni ngokusabalalisa ukushisa okulungiselelwe

I-Cross-Industry Compatibility: Ijwayelana neziko lokushuba, iziko elinezingqimba eziningi, kanye neziqhumiso zemhubhe ezixubile.

Ukusimama Kwezomnotho

Nakuba idinga ukutshalwa kwezimali kokuqala okuphezulu okungu-30-40% kunamarola avamile, izixazululo ze-R-SiC ziyabonisa:

- 70% wezikhawu zesevisi ezinde (iminyaka emi-5-7 vs. 2-3 iminyaka)

- 90% ukuphinda kusetshenziswe kabusha ngezinqubo zokuphinda zifakwe ezishisayo

- Izindleko zokulungisa eziphansi ngo-60% ezivela ezindaweni ezikwazi ukumelana nemihuzuko

I-Future-Ready Design

Amarola esimanje e-R-SiC manje ahlanganisa:

- Imisele yokulandela ngomkhondo eqoshwe nge-laser yemigqa yokukhiqiza ezenzakalelayo

- I-porosity eyenziwe ngokwezifiso ye-atmosphere permeability ethile

- Izinzwa ezishisayo ezididiyelwe zokusebenza kwe-smart kuhn

Le ntuthuko yezobuchwepheshe ibeka amarola e-silicon carbide asabelayo njengezinto ezibalulekile ezinhlelweni zokufudumeza zezimboni zesizukulwane esilandelayo, okuvumela abakhiqizi ukuthi bafinyelele ekulawuleni izinga lokushisa eliqinile, ukungaguquguquki okuphezulu komkhiqizo, kanye nokugeleza kokusebenza kokukhiqiza okuzinzile kuyo yonke imikhakha yobuchwepheshe obuphezulu.

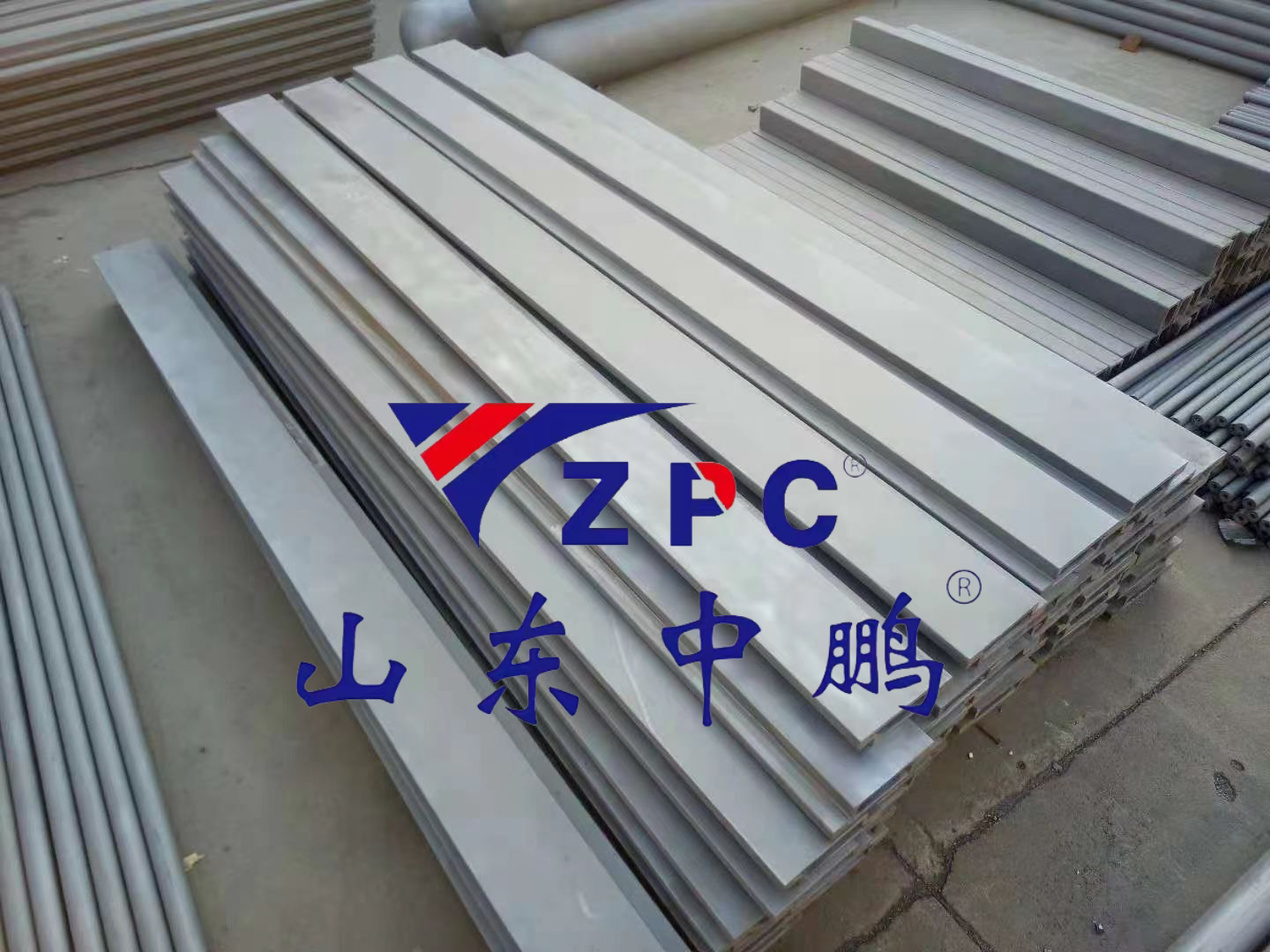

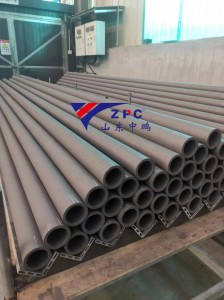

I-Shandong Zhongpeng Special Ceramics Co., Ltd ingesinye sezixazululo ezintsha ze-silicon carbide zobumba eChina. I-ceramic yobuchwepheshe ye-SiC: Ubulukhuni be-Moh buyi-9 (ukuqina kwe-Moh entsha yi-13), enokumelana okuhle nokuguguleka nokugqwala, ukuhuzuka okuhle kakhulu – ukumelana ne-oxidation. Impilo yesevisi yomkhiqizo we-SiC iyinde izikhathi ezi-4 kuya kwezi-5 kune-alumina material engu-92%. I-MOR ye-RBSiC izikhathi ezi-5 kuye kweziyi-7 kune-SNBSC, ingasetshenziselwa izimo eziyinkimbinkimbi. Inqubo yekhotheshini iyashesha, ukulethwa kunjengoba kuthenjisiwe futhi ikhwalithi ingeyesibili. Sihlala siphikelela ekuphonseni inselelo imigomo yethu futhi sibuyisele izinhliziyo zethu emphakathini.