Kusukela kumapayipi ezokuthutha kuya ezimotweni zamandla amasha, kusukela eziko lokushisa eliphezulu ukuya kumasathelayithi asemkhathini, into eyaziwa ngokuthi "idayimane lemboni" ibhala kabusha buthule imingcele yokukhiqiza yesimanje.I-silicone carbide ceramics, i-superhard material enobulukhuni okwesibili kuphela kwedayimane lemvelo, ibangela ukuguquka okuthulile emikhakheni ehlukahlukene efana nezimboni zesimanje, ama-semiconductors, i-aerospace, namandla amasha ngenxa yokumelana kwayo nezinga lokushisa eliphezulu, ukumelana nemisebe eqinile, kanye ne-conductivity enhle kakhulu yokushisa.

Lapho 'amathambo aqinile' ehlangabezana nokukhiqizwa okunembayo

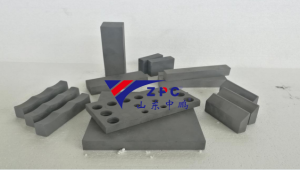

Uma izitsha zobumba ezivamile ziyi-porcelain eluhlaza okwesibhakabhaka nomhlophe kwezobuciko nemisebenzi yezandla, khona-ke izitsha zobumba ze-silicon carbide zifana kakhulu namawashi aseSwitzerland kumathuluzi anembayo. Ubulukhuni bayo buphindwe izikhathi ezingu-3-5 kobumba obuvamile, futhi lobu bunzima obuseduze namadayimane emvelo benza inqubo yokwenza imishini ifane nokubaza kumapuleti ensimbi - amathuluzi okusika ajwayelekile aguga ngesivinini esimangalisayo ngesikhathi sokusika. Okukhohlisa nakakhulu ukuthi imvelo “eqinile” ye-silicon carbide iyenza ijwayele ukuqhekeka ngisho nangephutha elincane ngesikhathi sokucutshungulwa, ikakhulukazi izingxenye ezithile ezinodonga oluncane ezidinga ukuqaphela okufanayo njengemisebenzi yobuciko yekristalu.

Kodwa isidingo semboni yesimanje siqhuba impumelelo kwezobuchwepheshe. Onjiniyela bathole ukuthi ukhiye ekuxazululeni le nkinga usekuhlanganisweni kokuqina nokuvumelana nezimo: ukugcinwa kwezakhiwo zangaphakathi zezinto ngenkathi kusetshenziswa ukulawula okunembayo phakathi nokucubungula. Njengabapheki abaphezulu abakwazi ukushisa, amasu esimanje okucubungula kancane kancane athambisa le nto enenkani ngokulawula okunembile kwezinga lokushisa, ingcindezi, kanye nemvamisa yokudlidliza.

Okhiye abathathu bokuvula amadayimane ezimboni

1. Ukucindezela okushisayo ukubumba

Lena enye yezindlela ezivame kakhulu zokucubungula i-silicon carbide ceramics. Le ndlela ibeka impushana ye-silicon carbide noma impushana exutshwe esikhunjeni esicindezelayo esishisayo futhi iyicubungule ibe yisimo ngaphansi kwezinga lokushisa eliphezulu nokucindezela. Isebenza kahle kakhulu ekukhiqizeni kanye nokwenza okunembayo, futhi ilungele ukukhiqiza imikhiqizo emikhulu ye-silicon carbide ceramic njengamathuluzi okusika, amapuleti e-aluminium adonsa ashisayo, njll.

2. Ukubunjwa kwe-grouting

Lena indlela eshibhile futhi esheshayo yokwakha imikhiqizo ye-silicon carbide ceramic. Le ndlela ixuba i-silicon carbide powder nezinye izithasiselo, izingeze emanzini ukwenza i-slurry, bese ijova isikhunta esibumbayo. Ngemva kwalokho, iyacutshungulwa futhi yakheke ngokomiswa kanye ne-high-temperature sintering, ngomjikelezo omfushane wokucubungula kanye nezindleko eziphansi. Kufanelekile ukulungiselela izingxenye eziqinile, eziphakeme kakhulu kanye nezingxenye ezithwala imithwalo.

3. I-powder metallurgy

I-powder metallurgy iyindlela yokuxuba nokubumba i-silicon carbide powder ngesilinganiso esithile, bese i-sintering ekushiseni okuphezulu nokucindezela okukhulu. Le ndlela inenqubo yokukhiqiza elula, ukubunjwa kwemikhiqizo ehlukahlukene, nokunemba okuphezulu kokucubungula, okuyenza ifanele ukukhiqiza imikhiqizo ye-ceramic enembayo ephezulu, ephezulu, nengagugi.

Kusukela kumasampula aselabhorethri kuya ekukhiqizeni ngobuningi emgqeni wokukhiqiza, impumelelo ekusetshenzisweni kwe-silicon carbide ceramics iqinisekisa iqiniso: ayikho into engakwazi ukucutshungulwa, ubuchwepheshe kuphela obungakaphulwa. Ngokuvuthwa kobuchwepheshe obusha obufana nokucubungula i-laser kanye ne-microwave sintering, le nto eyake yaba nzima kakhulu ivuselela emafekthri ahlakaniphile, ifaka amandla aqinile “embonini ehlakaniphile yaseShayina”.

Olwandle olukhulu lokuhlolwa komkhathi kanye negagasi eliluhlaza lamandla ahlanzekile, izitsha zobumba ze-silicon carbide zibhala inganekwane yezimboni yalesi sikhathi ngentelezi yazo eyingqayizivele. Lokhu kungqubuzana phakathi kobulukhuni nobuhlakani kungase kube umfanekiso waphakade wesintu oweqa imingcele yezobuchwepheshe.

Isikhathi sokuthumela: Apr-09-2025