I-Silicon carbide (SiC) i-ceramicszaziwa ngamandla azo amangalisayo, ukumelana nokushisa, nokuqina. Lezi zakhiwo zizenza zilungele ukusetshenziswa ezindaweni ezinzima, njengezinjini ze-aerospace noma imishini yezimboni. Kodwa zenziwa kanjani ngempela lezi zinto ezithuthukisiwe? Ake sihlukanise inqubo isinyathelo ngesinyathelo.

1.Ukulungiswa Kwempahla Engahluziwe

Konke kuqala nge-high-purity silicon carbide powder. Cabanga ngalokhu “njengofulawa” wokubhaka “ikhekhe” le-ceramic. Ukuze uthuthukise izici zento yokugcina, amanani amancane ezithasiselo—njenge-aluminium oxide noma izinhlanganisela ze-boron—ahlanganiswa. Lezi zithako zisebenza njengeglu ngezigaba zakamuva, zisiza izinhlayiya ukuthi zihlangane ngokuphumelelayo.

2. Ukubumba i-Ceramic

Impushana ibe isiguqulwa ibe yifomu elibumbekayo. Kusetshenziswa izindlela ezimbili ezijwayelekile:

Ukucindezela:Impushana icindezelwa ibe yisimo esithile kusetshenziswa ukucindezela okuphezulu, okufana nokuhlanganisa iqhwa libe yibhola leqhwa.

Ukubumba Umjovo: Impushana ixutshwa nesibophezelo sesikhashana (njenge-wax) ukuze kwakhiwe ingxube efana nenhlama, ejova isikhunta ukuze kube yizimo eziyinkimbinkimbi.

Kulesi sigaba, izinto zisantekenteke—njengomfanekiso oqoshiwe wesihlabathi esomile—futhi kudingeka “ubhakwe” ukuze uqine.

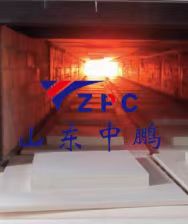

3. Inqubo Ye-Sintering

Yilapho kwenzeka khona umlingo. I-ceramic ebunjiwe ishiswa esithandweni esikhethekile emazingeni okushisa aphakeme kakhulu (ngokuvamile abe ngaphezu kuka-1,800°C). Ngesikhathi se-sintering, izinto ezimbili ezibalulekile zenzeka:

I-Particle Bond: Izinhlamvu ze-silicon carbide ziyasondelana, zisuse izikhala futhi zakhe isakhiwo esiqinile.

Umsebenzi Wezithasiselo: Izinhlanganisela ezingeziwe ziyancibilika kancane, zenze "ibhuloho" phakathi kwezinhlayiya ukuthuthukisa ukuqina.

Indawo engaphakathi kwesithando somlilo ilawulwa ngokucophelela—ngezinye izikhathi igcwaliswa amagesi angasebenzi—ukuze kuvinjelwe ukusabela okungafuneki.

4. Ukuqeda Ukuthintwa

Ngemuva kokucwiliswa, i-ceramic ingase ibhekane nokwelashwa okwengeziwe ukuze icolise ukusebenza kwayo:

Ukupholisha:Okwezinhlelo zokusebenza ezidinga izindawo ezibushelelezi (isb, izigxivizo noma ama-bearings).

I-Coating: Ungqimba oluncane oluvikelayo (njenge-silicon nitride) lungangezwa ukuze kuthuthukiswe ukumelana nokugqokwa.

Umshini: Ukusika okunembile noma ukubhola ukuze kuzuzwe ubukhulu bokugcina.

Kungani Le nqubo Ibalulekile

Imfihlo yamandla e-silicon carbide ilele ekutheni ama-athomu ayo ahlangana kanjani ngesikhathi sokucwiliswa. Inqubo yezinga eliphezulu lokushisa idala inethiwekhi yamabhondi e-silicon-carbon aqinile, amelana nokushisa, ukugqwala, nokucindezeleka ngokomzimba. Izithasiselo nokulawula izinga lokushisa okunembile kuqinisekisa ukuthi umkhiqizo wokugcina awunzima nje kuphela kodwa futhi uqinile ngokwanele ukumelana nokuqhekeka.

Isithombe Esikhulu

Ukusuka kuma-turbine asezingeni eliphezulu kuya ezinhlelweni zokulawula ukungcoliswa kwemvelo, izinto zobumba ze-silicon carbide zidlala indima ebalulekile kubuchwepheshe besimanje. Nakuba inqubo yokukhiqiza iyinkimbinkimbi, yilokhu kubhalansi okucophelelayo kwesayensi nobunjiniyela okushintsha impushana ibe into ekwazi ukumelana nezimo ezinzima kakhulu.

Njengoba ucwaningo luthuthuka, izindlela ezintsha—njengokuphrinta kwe-3D kwezitsha zobumba—ziyavela, zithembisa ukusetshenziswa okusha okwengeziwe kwalokhu kwaziswa okungajwayelekile.

Isikhathi sokuthumela: Mar-19-2025