Emkhakheni wezimboni, ukuthutha uketshezi oluqukethe izinhlayiya eziqinile kuwumsebenzi ovamile kodwa oyinselele kakhulu, njengokuthutha udaka ezimayini kanye nokuthutha umlotha ngokuphehla amandla ashisayo. Iphampu ye-slurry idlala indima ebalulekile ekuqedeni lo msebenzi. Phakathi kwamaphampu amaningi e-slurry,amaphampu e-silicon carbide impeller slurrykancane kancane baba umsizi onokwethenjelwa wezokuthutha zezimboni ngenxa yezinzuzo zabo eziyingqayizivele.

I-impeller yamaphampu ajwayelekile e-slurry ngokuvamile ayenziwe ngezinto zensimbi. Nakuba izinto zensimbi zinamandla athile kanye nokuqina, ziguga kalula futhi zigqwale lapho zibhekene noketshezi olunezinhlayiya ezibolayo neziqinile. Isibonelo, kwamanye amabhizinisi amakhemikhali, uketshezi oluthuthwayo luqukethe izinto ezine-asidi, futhi ama-impellers ensimbi ajwayelekile angagqwala ngokushesha, okuholela ekwehleni kokusebenza kwepompo nokushintshwa njalo kwama-impellers, okungathinti nje ukusebenza kahle kokukhiqiza kodwa futhi kwandisa izindleko.

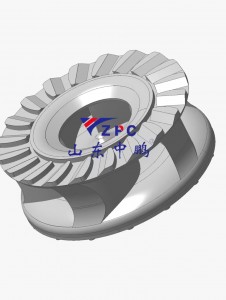

I-Silicon carbide impeller slurry pump ihlukile, "isikhali sayo esiyimfihlo" siyi-silicon carbide material. I-Silicon carbide iyinto enhle kakhulu ye-ceramic enobulukhuni obuphakeme kakhulu, okwesibili kuphela kwedayimane elinzima kakhulu ngokwemvelo. Lokhu kusho ukuthi uma uketshezi oluqukethe izinhlayiya eziqinile luthinta i-impeller ngesivinini esikhulu, i-silicon carbide impeller ingamelana ngokuphumelelayo nokuguga futhi inwebe kakhulu impilo yayo yesevisi.

Phakathi naleso sikhathi, izakhiwo zamakhemikhali ze-silicon carbide zizinzile futhi zingamelana nezinhlobo ezihlukahlukene zokugqwala. Kwezinye izimboni ezidinga ukuthuthwa koketshezi olubolayo, njenge-electroplating, imboni yamakhemikhali, njll., amaphampu e-silicon carbide impeller slurry angabhekana nawo kalula, agweme inkinga yokugqwala kwama-impellers ensimbi ajwayelekile futhi aqinisekise ukusebenza okuzinzile kwepompo.

Ngaphezu kokumelana nokugqoka nokugqwala, i-silicon carbide nayo inokuhamba okuhle kokushisayo. Ngesikhathi sokusebenza kwepompo, ukujikeleza kwejubane eliphezulu kwe-impeller kukhiqiza ukushisa, futhi i-silicon carbide ingakwazi ukususa ngokushesha ukushisa ukuze kuvimbele ukulimala kwe-impeller ngenxa yokushisa okuphezulu, kuthuthukise ngokwengeziwe ukuthembeka kwepompo.

Ekusetshenzisweni okungokoqobo, amaphampu e-silicon carbide impeller slurry nawo abonise izinzuzo ezibalulekile. Isibonelo, embonini yezimayini, lapho usebenzisa amaphampu ajwayelekile e-slurry, i-impeller ingase idinge ukushintshwa njalo ezinyangeni ezimbalwa. Kodwa-ke, ngokusetshenziswa kwamaphampu e-silicon carbide impeller slurry, umjikelezo wokubuyisela we-impeller unganwetshwa unyaka owodwa noma ngisho nangaphezulu, wehlise kakhulu isikhathi sokugcinwa kwemishini nezindleko, futhi uthuthukise ukusebenza kahle kokukhiqiza.

Nakuba iphampu ye-silicon carbide impeller slurry inezinzuzo eziningi, ayiphelele. Ngenxa yobulukhuni bezinto ze-silicon carbide, zingase zibe nokuqhekeka lapho zingaphansi kwamandla omthelela kungazelelwe. Kodwa-ke, ngokuthuthuka okuqhubekayo kobuchwepheshe, onjiniyela nabo bayathuthuka ngezindlela ezahlukahlukene, njengokwenza kahle ukwakheka kwe-impeller ukuze kusabalalise kangcono ingcindezi nokunciphisa ingozi yokuqhekeka.

Ngikholelwa ukuthi esikhathini esizayo, ngokuthuthukiswa okuqhubekayo kwesayensi yezinto zokwakha kanye nobuchwepheshe bokukhiqiza, ukusebenza kwamaphampu e-silicon carbide impeller slurry kuzoba okuphelele, futhi izicelo zabo zizoba ziningi, zilethe ukunethezeka kanye nezinzuzo emkhakheni wezokuthutha wezimboni.

Isikhathi sokuthumela: Jun-27-2025