nxiba i-silicon carbide iithayile zeceramic ezixhathisayo

![]()

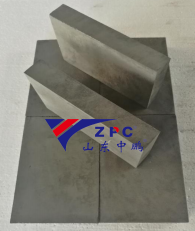

I-Reaction bonded silicon carbide (SiSiC okanye i-RBSIC) yeyona nto ifanelekileyo yokuxhathisa, eyimathiriyeli.

ngakumbi ilungele i-abrasive eyomeleleyo, amasuntswana arhabaxa, ulwahlulo, ugxininiso, ukuphelelwa ngamanzi emzimbeni kunye ne

eminye imisebenzi. Isetyenziswa ngokubanzi kwishishini lezimayini, ishishini lentsimbi, ishishini lokucubungula i-coral, imichiza

ishishini, ishishini lokwenza imathiriyeli ekrwada, ukutywinwa koomatshini, unyango lwesanti engaphezulu kunye nesibonisi njl.

Ngombulelo kubunzima obugqwesileyo kunye nokuchasana kwe-abrasive, kunokukhusela ngokufanelekileyo indawo apho imfuno yokunxiba

ukhuseleko, ukwenzela ukwandisa ubomi benkonzo yezixhobo.

Ungazichonga njani kwaye uzifumane njani iipleyiti ze-silicon carbide ezikwaziyo ukunxiba, iithayile, iilitha?

I-silicon carbide i-tiles-resistant-resistant tiles, i-liners, imibhobho iya isetyenziswa ngokubanzi kwishishini lemigodi.

Ezi ngongoma zilandelayo zezereferensi yakho:

1. Ifomula kunye nenkqubo:

Zininzi ii-SiC formulations kwimarike. Sisebenzisa iifomyula zaseJamani eziyinyani. Kuvavanyo olukwinqanaba eliphezulu lelebhu, imveliso yethu Ukhukuliseko ㎝³ ilahleko inokufikelela ku-0.85 ± 0.01;

2. Ukuqina:

Iithayile ze-SiC ziveliswa kwi-ZPC: ubunzima obutsha be-Mohs: 14.55 ± 4.5 (MOR, psi)

3. Ubuninzi:

Uluhlu lwe-tile ye-ZPC SiC yobuninzi malunga ne-3.03 + 0.05.

4. Ubungakanani kunye nomphezulu:

Iithayile zeSiC eziveliswe kwiZPC ngaphandle kokuqhekeka kunye neepores, ezinomgangatho osicaba kunye nemiphetho echanekileyo kunye neekona.

5. Imathiriyeli yangaphakathi:

I-Silicon carbide i-resistant-resistant liners / tiles zinezixhobo ezintle kwaye ezifanayo zangaphakathi nangaphandle.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Iinkcukacha:

| Into | Iyunithi | Idatha |

| Ubushushu besicelo | ℃ | 1380℃ |

| Ukuxinana | G/cm3 | -3.02 |

| I-porosity evulekile | % | <0.1 |

| Amandla okugoba -A | Mpa | 250 (20℃) |

| Amandla okugoba -B | MPa | 280 (1200℃) |

| Imodyuli ye-elasticity-A | GPA | 330(20℃) |

| Imodyuli yokunwebeka -B | GPA | 300 ( 1200℃ ) |

| I-Thermal conductivity | W/mk | 45 (1200℃) |

| I-Coefficient yokwandiswa kwe-thermal | K-1 × 10-6 | 4.5 |

| Ukuqina | / | 13 |

| I-alkaline enobungqina be-Acid | / | kuhle kakhulu |

■Imilo ekhoyo kunye nobukhulu:

Ubukhulu: ukusuka kwi-6mm ukuya kwi-25mm

Imilo eqhelekileyo: ipleyiti ye-SISIC, i-SISIC Pipe, i-SiSiC Three Links, i-SISIC Elbow, i-SISIC Cone Cyclone.

Phawula: Ezinye iisayizi kunye nemilo ziyafumaneka xa ziceliwe.

■Ukupakishwa:

Kwibhokisi yebhokisi, epakishwe kwiphalethi yeplanga enefumigated kunye nobunzima bomnatha 20-24MT/20′FCL.

■Iinzuzo eziphambili:

1. Ukumelana nokugqwesa okugqwesileyo, ukuchasana kwempembelelo kunye nokuxhathisa ukubola;

2. Ukuthe tyaba okugqwesileyo kunye nokumelana nobushushu obugqwesileyo ukuya kuthi ga kwi-1350 ℃

3. Ufakelo olulula;

4. Ubomi benkonzo ende (imalunga namaxesha ayi-7 ngaphezulu kobealumina ceramic namaxesha ali-10 ngaphezulu kowo

i-polyurethane

Ipateni ye-engile impembelelo ye-abrasion I-engile ephantsi sliding abrasion

Xa ukuhamba kwezinto ezirhawukayo kubetheka kwindawo egugileyo kwi-engile enganzulwanga okanye idlula ngokunxusene nayo, uhlobo lwesinxibo olwenzeka ngokukhuhlana lubizwa ngokuba yi-sliding abrasion.

Iiseramics ze-silicon carbide eziphucukileyo zibonelela ngokumelana nokunxiba kunye nokumelana nokugqwala kweethayile ze-ceramic kunye ne-lining. Ezi mveliso zibonakaliswe ukunxiba kwezixhobo ekuhambiseni, ekusetyenzweni nasekugcinweni kwazo. Iithayile zethu zinokuveliswa ngokutyeba ukusuka kwi-8 ukuya kwi-45mm. kubalulekile ukuqinisekisa ukuba unako ukufumana iimveliso ezifunekayo. I-SiSiC: Ubunzima be-Moh yi-9.5 (ubunzima be-Moh entsha yi-13), ngokuchasana okugqwesileyo kukhukuliseko kunye ne-corrosion, i-abrasion egqwesileyo - ukuxhathisa kunye ne-anti-oxidation. Inamandla ka-4 ukuya kwe-5 kune-nitride ebotshelelwe kwi-silicon carbide. Ubomi benkonzo buyi-5 ukuya kwamaxesha angama-7 ubude ngaphezu kwezinto ze-alumina. I-MOR ye-RBSiC yi-5 kumaxesha e-7 ye-SNBSC, ingasetyenziselwa imilo enzima ngakumbi. Ukunxitywa kwe-ceramic enganyangekiyo kwi-ceramic kuyasebenza ukwenza uphuculo lwentsebenzo yemveliso, ukusebenza kakuhle, ukuncitshiswa kweendleko zokulondolozwa kunye nokwanda kweengeniso.

Iiseramikhi ezichanekileyo zinolwazi lwezinto eziphathekayo, ubuchule obusetyenzisiweyo kunye nezakhono zobunjineli. Oku kunokuqinisekisa ngokufanelekileyo ukuba ezona zisombululo zilungileyo zinikezelwa kubathengi bethu. I-silicon carbide iileyile ze-ceramic kunye ne-lining zihlala zisetyenziselwa izicelo ezifana ne-cyclones, iityhubhu, i-chutes, i-hoppers, iipayipi, amabhande okuhambisa kunye neenkqubo zokuvelisa. Kwinkqubo, kukho izinto ezihambayo ezityibilikayo kumphezulu. Xa into ityibilika kwi-material, ithatha kancinane loo malungu kude kube kungabikho nto iseleyo. Kwiindawo zokunxiba okuphezulu, oku kunokwenzeka rhoqo kwaye kubangele iingxaki ezininzi ezibiza kakhulu. Isakhiwo esiphambili sigcinwa ngokusebenzisa izinto ezinzima kakhulu, ezifana ne-silicon carbide ceramics kunye ne-alumina ceramics njenge-lining yedini. Kwangaxeshanye, i-silicon carbide ceramics inokunyamezela ukunxiba ixesha elide ngaphambi kokuba itshintshwe, ubomi benkonzo ye-silicon carbide ceramic buphindwe ka-5 ukuya kwa-7 kunemathiriyeli ye-alumina.

Nxiba iiThayile zeCeramic eziNganyangekiyo zeSilicon Carbide kunye neePropati zeLining:

Ukumelana neekhemikhali

Ukhuselo lombane

Ukhukuliseko lokusetyenziswa koomatshini kunye nokumelana nokukrazuka

Inokubuyiselwa

Izinto eziluncedo kwiCeramic Wear Resistant Tiles & Linings:

Inokusetyenziswa apho unyamezelo oluqinileyo okanye iilena ezibhityileyo zifuneka

Inokusetyenziselwa ukuphinda ivele kwakhona iindawo esele ziqhele ukunxitywa

Inokusetyenziswa ngeendlela ezininzi zokuncamathisela ezifana ne-welding kunye ne-adhesives

Isiko eliyilelwe usetyenziso oluthile

Ukumelana nomhlwa kakhulu

Isisombululo sokunciphisa ukunxiba okulula

Ikhusela iindawo ezihambayo eziphantsi kobume bemeko yokunxiba okuphezulu

Igqithisa ngokubonakalayo kwaye igqwesa izisombululo zokunciphisa ukunxiba

Ubushushu bokusetyenziswa kakhulu obuphezulu ukuya kuthi ga kwi-1380°C

1, Intsimbi kunye plant steel: 1, sintering machine igubu mixer lining 2, igubu esongelwe irabha ceramic 3, fan impeller 4, idiskhi feeder, umkhombe izinto ezomileyo 5, coke hopper, umgqomo converter, coke bin, inkanyamba umqokeleli uthuli.

2, Iplanti yamandla: 1. Indawo yokusila yebhola, ilitye lokusila, isantya esiphakathi sokusila, ingqiniba yombhobho, umqokeleli wothuli lwenkanyamba, isililo, ihopper 2, ihopper yamalahle, isahluli somgubo orhabaxa kunye nomgubo ocolekileyo, indawo yokusila yamalahle, ihopper ehambisa amalahle yebhulorho, ibhulorho ebanjwa, iziko le-coal kunye ne-milllet ye-coal outlet. yesahluli somgubo orhabaxa kunye ocolekileyo, umthamo wombhobho ombhobho 4 Iindidi ezahlukeneyo zombane othe ngqo, ojikelezayo oshinyeneyo kwaye ongcungcuthekisayo izitshisi ezikwaziyo ukumelana nobushushu obuphezulu kwizibilisi ezibaswa ngamalahle; imibhobho edityanisiweyo ye-ceramic ene-high-resistant kunye nengqiniba, izitshisi ze-ceramic, iifeni ze-ceramic, ii-impeller ze-ceramic, iivalvu ze-ceramic, njl.; iindawo ezahlukeneyo zokunxiba ezifana neebhola zokusila, imikhono eqengqelekayo, iidiski zokusila, iithayile zediski, iiringi zokusila, iibhola zombhobho kunye nezinye iindawo ezikwaziyo ukunxiba kwimill yamalahle esantya esiphakathi; imibhobho, i-damper-resistant-resistant damper kunye neefeni zemigaqo eyahlukeneyo yokucoca kunye neenkqubo zokususa uthuthu; Iibhola Zonke iintlobo zelitye lokusila zine (okanye aziyi) zinethayile yolwala lwebholiti, ipleyiti yomgca, umbhobho ojikelezayo, umsesane wegiya, ibhola yentsimbi ephantsi yechromium, njl. njl.; ivili elibethayo, ipleyiti yokubetha, ihuku yokulinda, isikrweqe, isahluli, umbhobho werhasi wobushushu obuphezulu, njl. izincedisi ezifunekayo kwiintlobo ezahlukeneyo zoomatshini bokutyumza.

3, Iphepha lokusila: 1. Umbhobho wamalahle ocoliweyo

Iimveliso kunye neenkonzo eziphambili: 1. Imibhobho ye-ceramic engagugiyo kwimizi-mveliso: zonke iintlobo zeeramic ezixhathisayo kunye nobushushu obuphezulu obugqunywe ngamalahle axonxiweyo, iintsalela zezimbiwa, uludaka lwe-slag, umbhobho wokuthutha oludaka, ingqiniba, ingqiniba, isitshisi samalahle esivundiweyo, indawo yokusila yamalahle, i-coarte cycling, i-coarte cycling, i-coarte cycloparator umgqomo wokunxiba wesahluli somgodi wemagnethi; 2. Nxiba ifeni ye-ceramic exhathisayo: zonke iintlobo zokumelana nobushushu obuphezulu, ukumelana nokunxiba, i-anti-corrosion fan impeller kunye nevolute, kubandakanya fan ye-centrifugal, i-axial flow fan, i-static blade, i-blade eshukumayo etshintshayo i-fan impeller, i-suction fan, i-powder exhauster, i-sintering fan, ifeni yokwahlula umgubo, ukususwa kwentloko yothuli kunye nefenisha ye-kil 3. Nxiba impompo yombane ye-ceramic enganyangekiyo kunye nevalve: i-ceramic lining, i-pump impeller, i-shell, i-baffle, i-elbow yombhobho, ukususwa kothuthu lwe-pneumatic kunye nevalve yokuhambisa igesi kunye nezixhobo ze-slurry ezahlukeneyo, i-slag slurry, i-mortar, i-tailings kunye nezinye iinkqubo zokuthutha. 4. Nxiba iingubo ze-ceramic ezixhathisayo: zonke iintlobo ze-ceramic resistant kunye nobushushu obuphezulu obuxhathisayo kunye ne-mastic zisetyenziselwa i-fan volute, i-elbow pipe, i-outlet ye-mill, i-coarse kunye ne-fine separator pipe, i-chute, i-hopper kunye ne-valve. 5. Nxiba izixhobo zokwahlula imagnethi ezixhathisayo: iinxalenye zokuhamba okuhambayo kwezixhobo ezahlukeneyo zokusetyenzwa kwezimbiwa ezomileyo nezimanzi, kubandakanywa igubu lokwahlula imagnethi, umjelo ongezantsi, i-chute, umbhobho, iimpompo ezahlukeneyo zodaka, i-slurry pump volute, i-impeller, kunye nombhobho ohambisayo. 6. Itekhnoloji yokutshiza i-Surface: usebenzisa i-international inverter pulse arc power supply kunye ne-high-speed arc spraying gun, izinto ezahlukeneyo zetsimbi ezinganyangekiyo kunye ne-anti-corrosion zifafazwe kwi-metal substrate surface ukuze zenze umaleko okhuselayo wokuguga kunye ne-anti-corrosion. Inokubonelela ngokhuseleko olusebenzayo kuzo zonke iintlobo ze-corrosion yamandla aphakathi.

I-Shandong Zhongpeng ZPC iiseramikhi lishishini elikhethekileyo ekuvelisweni kweeseramikhi zamashishini, ezizibandakanya ikakhulu kwi-R & D kunye nokuveliswa kweeseramics zesilicon carbide. Singakwazi ukucubungula iimveliso ze-ceramic ngokwemizobo yakho, ngokukodwa kwimveliso yobukhulu obukhulu, intonga ye-ceramic echanekileyo, umbhobho we-ceramic, umsesane we-ceramic, ipleyiti ye-ceramic, i-flange ye-ceramic, i-nozzle ye-ceramic, kunye nobukhulu obukhulu obungagungqiyo.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zikhulu ze-silicon carbide zeceramic ze-ceramic e-China. I-ceramic yobugcisa be-SiC: Ubulukhuni be-Moh yi-9 (ubulukhuni be-Moh entsha yi-13), kunye nokuchasana okugqwesileyo kukhukuliseko kunye nokugqwala, i-abrasion egqwesileyo - ukuxhathisa kunye ne-anti-oxidation. Ubomi benkonzo yemveliso ye-SiC yi-4 ukuya kwamaxesha ama-5 ubude ngaphezu kwe-92% yezinto ze-alumina. I-MOR ye-RBSiC yi-5 kumaxesha e-7 ye-SNBSC, ingasetyenziselwa imilo enzima ngakumbi. Inkqubo yekoteyishini ikhawuleza, ukuhanjiswa kuthenjisiwe kwaye umgangatho ungowesibini. Sihlala sizingisa ukucela umngeni kwiinjongo zethu kwaye sibuyisele iintliziyo zethu kuluntu.