ISilicon Carbide FGD Nozzle ye-desulfurization kwiplanti yamandla

Imilomo yokufunxa iGesi yeFlue (FGD).

Ukususwa kwe-sulfure oxides, ngokuqhelekileyo ebizwa ngokuba yi-SOx, kwi-exhaust gases usebenzisa i-alkali reagent, efana ne-limestone slurry emanzi.

Xa iifosili zisetyenziswa kwiinkqubo zokutsha zokuqhuba izibilini, iziko, okanye ezinye izixhobo ezinokuthi zikhulule i-SO2 okanye i-SO3 njengenxalenye yegesi yokukhupha. Ezi oxide zesulfure zisabela ngokulula kunye nezinye izinto ukwenza ikhompawundi eyingozi njenge-asidi ye-sulfuric kwaye inamandla okuchaphazela kakubi impilo yabantu kunye nokusingqongileyo. Ngenxa yezi ziphumo zinokwenzeka, ulawulo lwale khompawundi kwiigesi zombhobho yinxalenye ebalulekileyo yezityalo zamandla ezibaswa ngamalahle kunye nezinye izicelo zemizi-mveliso.

Ngenxa yokhukuliseko, ukuplaga, kunye neenkxalabo zokwakha, enye yezona nkqubo zithembekileyo zokulawula oku kukhutshwa yinkqubo evulekileyo ye-wet flue gas desulfurization (FGD) usebenzisa i-limestone, i-hydrated lime, amanzi olwandle, okanye esinye isisombululo se-alkaline. Imilomo yokutshiza iyakwazi ukusasaza olu daka ngokufanelekileyo nangokuthembekileyo kwiinqaba zokufunxa. Ngokwenza iipateni ezifanayo zamathontsi anobungakanani obufanelekileyo, le mibhobho iyakwazi ukwenza ngokufanelekileyo indawo engaphezulu efunekayo ukufunxa ngokufanelekileyo ngelixa kuncitshiswa ukunyanzeliswa kwesisombululo sokukhuhla kwirhasi yomkhuhlane.

Ukukhetha iFGD Absorber Nozzle:

Imiba ebalulekileyo ekufuneka iqwalaselwe:

Ukukhuhla ingxinano yemidiya kunye ne-viscosity

Ubungakanani obufunekayo bethontsi

Ubungakanani obuchanekileyo bethontsi buyimfuneko ekuqinisekiseni amazinga afanelekileyo okufunxa

Imathiriyeli yombhobho

Njengoko irhasi yeflue ikholisa ukugqwesa kwaye ulwelo lokukhuhla luhlala luludaka olunomxholo ophezulu wezinto eziqinileyo kunye neempawu ezirhabaxa, ukukhetha umhlwa ofanelekileyo kunye nokunxiba izinto ezixhathisayo kubalulekile.

Ukumelana nokuvala umlomo wombhobho

Njengoko ulwelo lokukhuhla luhlala luludaka olunomxholo ophezulu wezinto eziqinileyo, ukukhetha umlomo malunga nokuxhathisa i-clog kubalulekile.

Ipateni yokutshiza yeNozzle kunye nokubekwa

Ukuze kuqinisekiswe ukufunxwa okufanelekileyo kogutyulo olupheleleyo lomjelo werhasi ngaphandle kokudlula kunye nexesha elaneleyo lokuhlala libalulekile.

Ubungakanani boqhagamshelwano lombhobho kunye nohlobo

Amazinga okuhamba kwamanzi okukhuhla okufunekayo

Uxinzelelo olukhoyo lwehla (∆P) ngapha komlomo

∆P = unikezelo loxinzelelo kwindawo yokungena embhobho – inkqubo yoxinzelelo ngaphandle kombhobho

Iinjineli zethu ezinamava zinokukunceda ukufumanisa ukuba yeyiphi na umlomo wombhobho oza kusebenza njengoko kufuneka ngeenkcukacha zakho zoyilo

Usetyenziso oluqhelekileyo lwe-FGD Absorber Nozzle kunye namashishini:

Amalahle kunye nezinye izibaso zamandla efosili

Iimveliso zepetroleum

Izitshisi zenkunkuma zikamasipala

Iziko lesamente

Izinyibilikisi zesinyithi

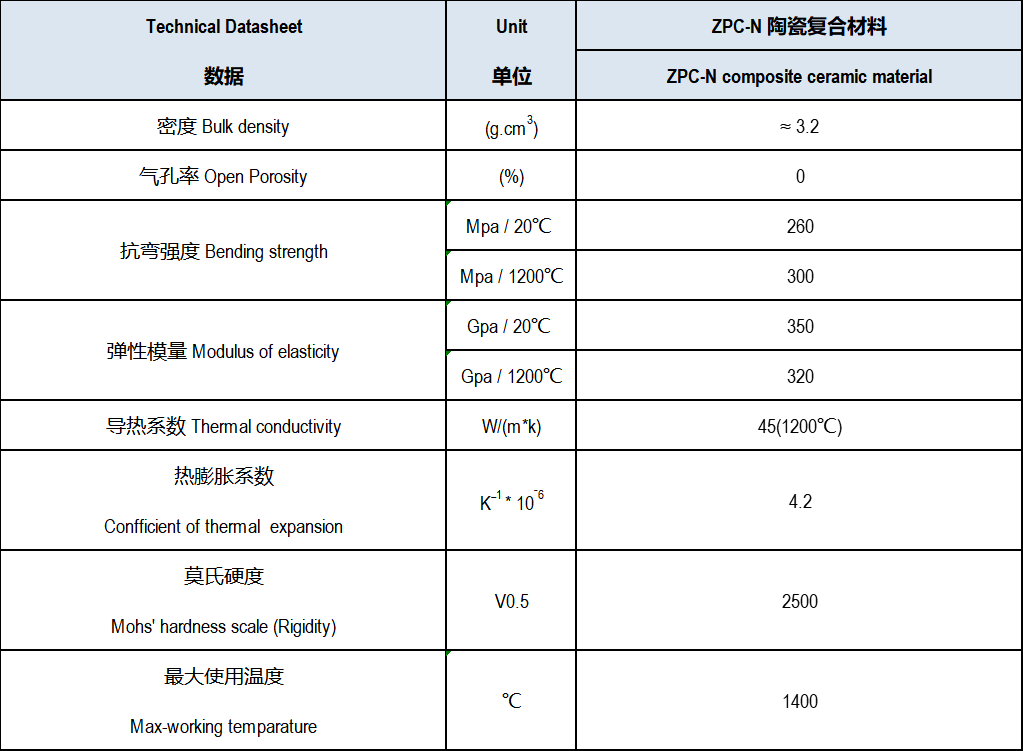

I-SiC Material Datasheet

Ukungaphumeleli ngeLime/Limestone

Njengoko kubonisiwe kuMfanekiso 1, iinkqubo ze-FGD ezisebenzisa i-limestone ngenkani ye-oxidation (LSFO) ibandakanya iinkqubo ezingaphantsi ezintathu:

- Ukulungiswa kwe-reagent, ukuphatha kunye nokugcinwa

- Isitya sokufunxa

- Inkunkuma kunye nokuphathwa kwemveliso

Ukulungiswa kwesixhobo sokusebenza kwakhona kubandakanya ukuhanjiswa kwelitye lekalika elityumkileyo (CaCO3) ukusuka kwisisele sokugcina ukuya kwitanki yesondlo ephazamisekileyo. Isiphumo sodaka lwelimestone luthi lumpontshelwe kwisikhephe sokufunxa kunye negesi yebhoyila kunye ne-oxidizing air. Imilomo yezitshizi ihambisa amathontsi acolekileyo esixhobo esiphinda-phindeneyo athi aqukuqelele ngokuchasene nerhasi yombane engenayo. I-SO2 kwi-flue gas isabela kunye ne-calcium-rich reagent ukwenza i-calcium sulfite (CaSO3) kunye ne-CO2. Umoya ongeniswe kwi-absorber ukhuthaza i-oxidation ye-CaSO3 kwi-CaSO4 (ifom ye-dihydrate).

Iimpendulo ezisisiseko ze-LSFO zezi:

CaCO3 + SO2 → CaSO3 + CO2 · 2H2O

Udaka oluxutywe neoksijini luqokelela emazantsi esixhobo sokufunxa kwaye emva koko siphinde sisetyenziswe kwakhona kunye ne-reagent entsha ebuyela kwizihloko zomlomo wesitshizi. Inxalenye yomjelo wokurisayikilisha irhoxiswa kwinkqubo yokuphatha inkunkuma/yemveliso, ebandakanya ii-hydrocyclones, idrum okanye izihluzi zebhanti, kunye netanki ephazamisayo yamanzi amdaka/ezotywala. Amanzi amdaka asuka kwitanki yokubamba ayarisayikilishwa abuyiselwe kwitanki yokutya ye-limestone okanye kwi-hydrocyclone apho ukuphuphuma kwawo kususwa njengamanzi amdaka.

| Ikalika eqhelekileyo/iLimestone eNyanzeliswa yiOxidatin yeNkqubo yokuKhuhla okuManzi |

|

Iinkqubo ze-LSFO ezimanzi ngokuqhelekileyo zinokufikelela kwi-SO2 yokususa i-95-97 ekhulwini. Ukufikelela kumanqanaba angaphezu kwe-97.5 yeepesenti ukuhlangabezana neemfuno zokulawula ukukhutshwa, nangona kunjalo, kunzima, ngakumbi kwizityalo ezisebenzisa amalahle aphezulu esulfure. I-Magnesium catalysts inokongezwa okanye i-limestone ingabalwa kwi-lime ephezulu ye-reactivity (CaO), kodwa ukuguqulwa okunjalo kubandakanya izixhobo zeplanti ezongezelelweyo kunye neendleko zokusebenza kunye namandla ahambelanayo. Ngokomzekelo, i-calcining kwikalika idinga ukufakwa kwe-lime ye-lime eyahlukileyo. Kwakhona, i-lime iyancipha ngokukhawuleza kwaye oku kwandisa amandla okwenziwa kwediphozithi yesikali kwi-scrubber.

Iindleko zokubala nge-lime kiln zinokuncitshiswa ngokufaka i-limestone ngokuthe ngqo kwisithando somlilo. Kule ndlela, i-lime eyenziwe kwibhoyili ithwalwa nge-flue gas kwi-scrubber. Iingxaki ezinokubakho ziquka ukonakala kwebhoyila, ukuphazamisana nokuhanjiswa kobushushu, kunye nokungasebenzi kwekalika ngenxa yokutshisa kakhulu kwibhoyila. Ngaphezu koko, ikalika yehlisa ubushushu bokuhamba kothuthu olunyibilikisiweyo kwizibiyeli ezibaswa ngamalahle, nto leyo ekhokelela kwiidiphozithi eziqinileyo ebezingayi kwenzeka.

Inkunkuma yolwelo evela kwinkqubo ye-LSFO iqhele ukujoliswa ekuzinziseni amachibi kunye nenkunkuma engamanzi evela kwenye indawo kumzimveliso wamandla. Ulwelo olumanzi lwe-FGD lunokuthi luzaliswe yi-sulfite kunye neekhompawundi zesulfate kwaye iingqwalaselo zokusingqongileyo ngokuqhelekileyo zinciphisa ukukhutshwa kwazo kwimilambo, imisinga okanye eminye imijelo yamanzi. Kwakhona, ukuphinda kusetyenziswe amanzi amdaka / utywala ukubuyisela kwi-scrubber kunokukhokelela ekwakhiweni kwe-sodium, i-potassium, i-calcium, i-magnesium okanye i-chloride salts. Ezi ntlobo zinokuthi ekugqibeleni zikhazimle ngaphandle kokuba kubonelelwe ukopha okwaneleyo ukugcina ityuwa enyityilisiweyo ingaphantsi komlinganiselo. Ingxaki eyongezelelweyo yinqanaba elicothayo lokuzinzisa inkunkuma eqinileyo, nto leyo ebangela ukuba kufuneke amachibi amakhulu, anomthamo omkhulu wokuzinzisa. Kwiimeko eziqhelekileyo, umaleko ozinzileyo echibini lokuzinzisa unokuqulatha ipesenti ezingama-50 okanye ngaphezulu kwesigaba solwelo nasemva kweenyanga ezininzi zokugcina.

I-calcium sulfate efunyenwe kwi-absorpr recycle slurry ingaba phezulu kwi-limestone engasasetyenziswanga kunye nothuthu lwe-calcium sulfite. Ezi zingcolisi zinokuthintela i-calcium sulfate ekuthengisweni njengegypsum yokwenziwa ukuze isetyenziswe kwi-wallboard, udaka kunye nokuveliswa kwesamente. I-limestone engaphendulwanga kokona kungacocekanga kuxhaphakileyo okufumaneka kwigypsum yokwenziwa kwaye ikwakukungacoceki okuqhelekileyo kwigypsum yendalo (embiweyo). Ngelixa i-limestone ngokwayo ayiphazamisi kwiipropathi zeemveliso zokuphela kwe-wallboard, iipropathi zayo ezirhabaxa zibonisa imiba yokunxiba yezixhobo zokusebenza. I-calcium sulfite kukungacoceki okungafunekiyo kuyo nayiphi na i-gypsum njengoko ubungakanani bayo obucolekileyo bubangela iingxaki zokulinganisa kunye nezinye iingxaki zokulungisa ezifana nokuhlamba ikhekhe kunye nokukhupha amanzi.

Ukuba izinto eziqinileyo ezenziwe kwinkqubo ye-LSFO azithengiswa njengegypsum yokwenziwa, oku kubangela ingxaki enkulu yokulahlwa kwenkunkuma. Kwibhoyila ye-1000 MW edubula i-1 ekhulwini lamalahle esalfure, isixa segypsum simalunga neetoni ezingama-550 (mfutshane)/ngosuku. Kwakwesi sityalo sidubula i-2 yepesenti yamalahle esalfure, imveliso yegypsum iyanda ukuya kutsho malunga neetoni ezili-1100 ngosuku. Ukongeza malunga ne-1000 yeetoni ngosuku kwimveliso yothuthu lwempukane, oku kuzisa itoni yenkunkuma eyomeleleyo ukuya kwi-1550 yeetoni/ngosuku kwi-1 yepesenti yeetoni zamalahle esalfure kunye ne-2100 yeetoni ngosuku kwi-2 yepesenti yesulfure case.

I-EADS eluncedo

Itekhnoloji eqinisekisiweyo eyenye endaweni yokukhuhla i-LSFO ithatha indawo yekalika nge-ammonia njengesixhobo sokususa i-SO2. I-reagent reagent eqinile yokugaya, ukugcinwa, ukuphatha kunye nokuthutha amacandelo kwinkqubo ye-LSFO ithathelwa indawo ngamatanki alula okugcina i-ammonia enamanzi okanye i-anhydrous. Umzobo 2 ubonisa iskimu sokuhamba kwenkqubo ye-EADS ebonelelwa yiJET Inc.

I-ammonia, irhasi yombane, umoya oxonxisa ioksijini kunye namanzi acutshungulwayo angena kwisixhobo sokufunxa esiqulethe amanqanaba amaninzi emilomo yokutshiza. Imilomo ivelisa amathontsi acolekileyo ereagent equlathe iammonia ukuqinisekisa unxibelelwano olusondeleyo lwe-reagent kunye nerhasi yombane engenayo ngokwezi mpendulo zilandelayo:

(1) SO2 + 2NH3 + H2O → (NH4)2SO3

(2) (NH4)2SO3 + ½O2 → (NH4)2SO4

I-SO2 kumjelo werhasi yeflue idibana ne-ammonia kwisiqingatha esiphezulu senqanawa ukuvelisa i-ammonium sulfite. Umzantsi wesitya sokufunxa usebenza njengetanki ye-oxidation apho umoya oxidizes i-ammonium sulfite kwi-ammonium sulfate. Isiphumo sesisombululo se-ammonium sulfate simpontshwa sibuyele kwintloko yomlomo wesitshizi kumanqanaba amaninzi kwisibambisi. Phambi kwerhasi ekhuhlayo ephuma kumphezulu wesixhobo sokufunxa, idlula kwi-demister edibanisa nawaphina amathontsi olwelo afakiweyo kwaye ibambe amasuntswana amahle.

Ukusabela kwe-ammonia nge-SO2 kunye ne-sulfite oxidation kwi-sulfate ifezekisa izinga eliphezulu lokusetyenziswa kwe-reagent. Iipounds ezine ze-ammonium sulfate ziveliswa ngeponti nganye yeammonia esetyenzisiweyo.

Njengenkqubo ye-LSFO, inxalenye ye-reagent / i-recycle stream yemveliso inokurhoxiswa ukuvelisa imveliso yorhwebo. Kwinkqubo ye-EADS, isisombululo semveliso yokuthatha i-solid sipompa kwinkqubo yokubuyisela i-solids equkethe i-hydrocyclone kunye ne-centrifuge ukugxila kwimveliso ye-ammonium sulfate ngaphambi kokumisa kunye nokupakisha. Zonke izinto ezingamanzi (i-hydrocyclone ephuphumayo kunye ne-centrifuge centrate) zibuyiselwa emva kwitanki ye-slurry kwaye ziphinde zifakwe kwi-absorber ammonium sulfate recycle stream.

- Iinkqubo ze-EADS zibonelela ngobuchule obuphezulu bokususwa kwe-SO2 (>99%), enika izixhobo zamandla ezibaswa ngamalahle ukuba zibe bhetyebhetye ngakumbi ukuze zidibanise amalahle angabizi kakhulu, aphezulu esulfure.

- Nangona iinkqubo ze-LSFO zenza i-0.7 yeetoni ze-CO2 kwitoni nganye ye-SO2 esusiweyo, inkqubo ye-EADS ayivelisi i-CO2.

- Ngenxa yokuba ikalika kunye ne-limestone zisebenza kancinci xa kuthelekiswa ne-ammonia yokususwa kwe-SO2, inkqubo ephezulu yokusetyenziswa kwamanzi kunye namandla okumpompa kuyafuneka ukuze kuphunyezwe amazinga aphezulu okujikeleza. Oku kubangela iindleko eziphezulu zokusebenza kwiinkqubo ze-LSFO.

- Iindleko ezinkulu kwiinkqubo ze-EADS ziyafana nezo zokwenza inkqubo ye-LSFO. Njengoko kuphawuliwe ngasentla, ngelixa inkqubo ye-EADS idinga i-ammonium sulfate byproduct processing kunye nezixhobo zokupakisha, izibonelelo zokulungiselela i-reagent ehambelana ne-LSFO ayifuni ukugaya, ukuphatha kunye nokuthutha.

Olona ncedo lwahlukileyo lwe-EADS kukupheliswa kwenkunkuma engamanzi kunye neqinileyo. Itekhnoloji ye-EADS yinkqubo yokukhupha i-zero-liquid-discharge, nto leyo ethetha ukuba akukho mfuneko yokucocwa kwamanzi amdaka. I-solid ammonium sulfate byproduct iyathengiswa ngokulula; i-ammonia sulfate sesona sichumiso sisetyenziswayo kunye necandelo lesichumisi kwihlabathi, ngokukhula kwemarike yehlabathi jikelele kulindeleke ngo-2030. Ukongeza, ngelixa ukwenziwa kwe-ammonium sulfate kufuna i-centrifuge, isomisi, i-conveyer kunye nezixhobo zokupakisha, ezi zinto azikho kwaye zifumaneka ngorhwebo. Ngokuxhomekeke kwiimeko zoqoqosho kunye neemarike, isichumiso se-ammonium sulfate sinokuhlawulela iindleko ze-ammonia-based flue gas desulfurization kwaye sinokubonelela ngenzuzo enkulu.

| Esebenzayo Ammonia Desulfurization Inkqubo Schematic |

|

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zikhulu ze-silicon carbide zeceramic ze-ceramic e-China. I-ceramic yobugcisa be-SiC: Ubulukhuni be-Moh yi-9 (ubulukhuni be-Moh entsha yi-13), kunye nokuchasana okugqwesileyo kukhukuliseko kunye nokugqwala, i-abrasion egqwesileyo - ukuxhathisa kunye ne-anti-oxidation. Ubomi benkonzo yemveliso ye-SiC yi-4 ukuya kwamaxesha ama-5 ubude ngaphezu kwe-92% yezinto ze-alumina. I-MOR ye-RBSiC yi-5 kumaxesha e-7 ye-SNBSC, ingasetyenziselwa imilo enzima ngakumbi. Inkqubo yekoteyishini ikhawuleza, ukuhanjiswa kuthenjisiwe kwaye umgangatho ungowesibini. Sihlala sizingisa ukucela umngeni kwiinjongo zethu kwaye sibuyisele iintliziyo zethu kuluntu.