Iithayile zeCeramic zeSilicon Carbide

Yenzelwe ukumelana nemiceli mngeni yokusebenza kakhulu,iithayile ze-silicon carbideiye yaba yeyona nto ibalulekileyo kumashishini afuna ukhuseleko lokunxiba olungayekeleliyo. I-microstructure yayo ekhethekileyo ihambisa umsebenzi obalaseleyo kwi:

-Izowuni zokurhawuka ezinzima ezibamba amasuntswana arhabaxa (>5mm)

- Ulwahlulo olunempembelelo ephezulu kunye neenkqubo zokususa amanzi

- Uthutho lwemidiya eyonakalisayo kwi-coral processing kunye nezityalo zekhemikhali

Ukusuka kubahambisi be-slag bentsimbi ukuya kubuso obutywiniweyo kwimveliso yezinto ezikrwada,iithayile ze-silicon carbideAmalungu asebenza njengesikrweqe sobunjineli - ngokuchanekileyo akhusele iindawo zokunxiba ezibalulekileyo ngelixa ugcina uzinzo phantsi koxinzelelo oluqhubekayo.

Njengoko imfuno inyuka yeethayile ze-silicon carbide, iilitha, kunye nemibhobho kuwo wonke amatyathanga okulungisa izimbiwa, abathengi abaqondayo kufuneka babeke phambili ezi benchmarks:

1. Uqulunqo oluqhutywa liLifa leMveli

Ikhompawundi yethu yemvelaphi yaseJamani ivavanywa ngokhukuliseko oluninzi, ukufikelela kumazinga elahleko yemathiriyeli engaphantsi kwe-0.86㎝³-ubungqina bokuthembeka kweethayile ze-silicon carbide matrix.

2. IProtokholi yoQinisekiso loBulukhuni

Iithayile ze-silicon ze-carbide zifumana imephu yoxinzelelo lwe-triaxial, ebonisa i-14.55±4.5 ubulukhuni be-Mohs obutsha kunye ne-≤2% i-MOR eyahlukileyo kwiibhetshi zemveliso.

3. Ulawulo lokuNxinana ngokuChaneka

I-substandard sintering idala ubuthathaka bolwakhiwo. Inkqubo yethu yeethayile ze-silicon carbide igcina i-3.03±0.05g/㎝³ ingxinano ngokusebenzisa i-proprietary-assisted reaction bonding, isusa i-subsurface voids.

4. Ukugqibelela kweJometri

▸ Ukuthe tyaba komphezulu oqinisekiswe ngeLaser (<0.02mm/m²)

▸ Umphetho werediyasi ukuhambelana (0.5±0.1mm)

▸ Isiqinisekiso se-100% se-crack/i-pore-free

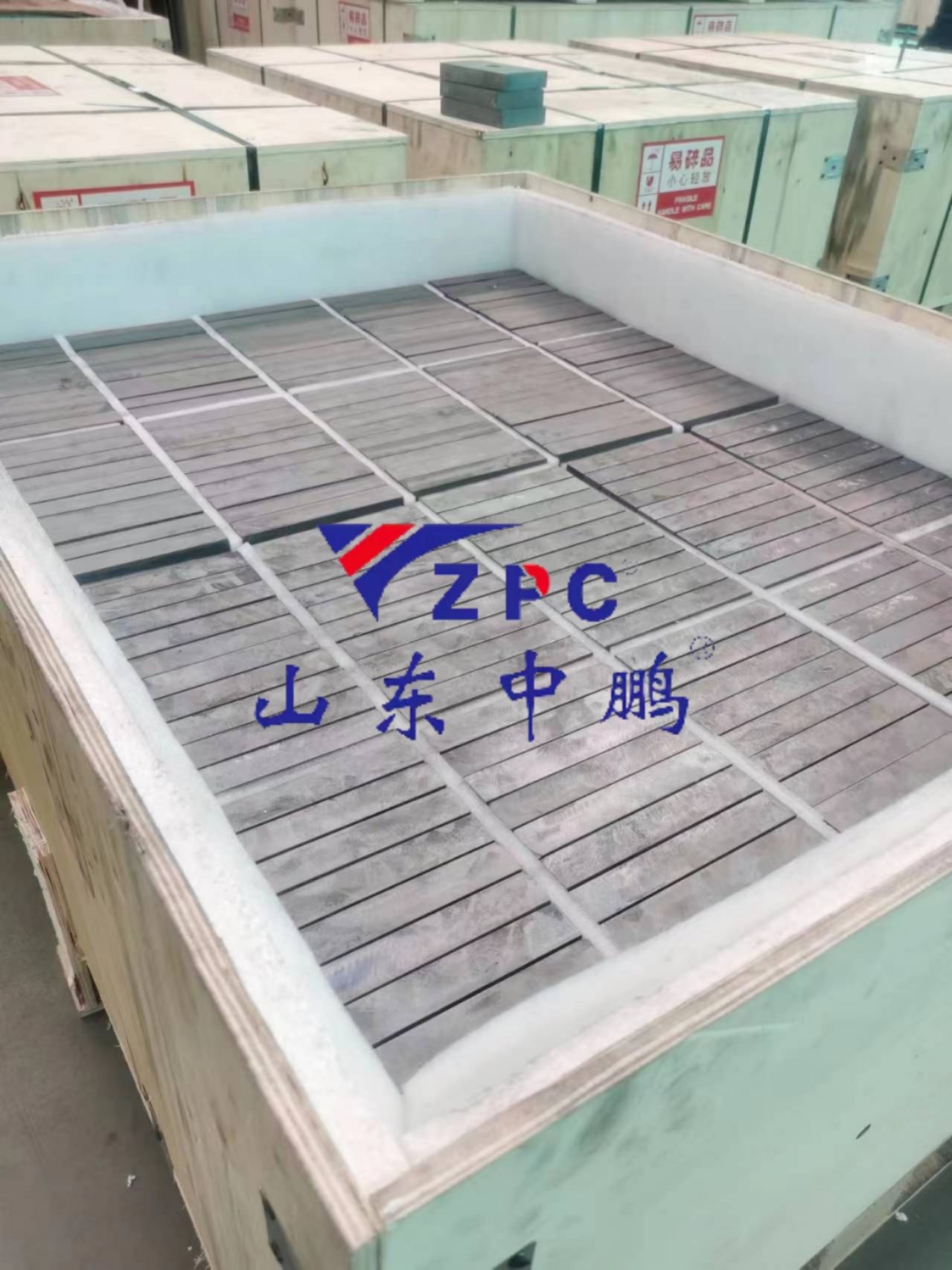

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zikhulu ze-silicon carbide zeceramic ze-ceramic e-China. I-ceramic yobugcisa be-SiC: Ubulukhuni be-Moh yi-9 (ubulukhuni be-Moh entsha yi-13), kunye nokuchasana okugqwesileyo kukhukuliseko kunye nokugqwala, i-abrasion egqwesileyo - ukuxhathisa kunye ne-anti-oxidation. Ubomi benkonzo yemveliso ye-SiC yi-4 ukuya kwamaxesha ama-5 ubude ngaphezu kwe-92% yezinto ze-alumina. I-MOR ye-RBSiC yi-5 kumaxesha e-7 ye-SNBSC, ingasetyenziselwa imilo enzima ngakumbi. Inkqubo yekoteyishini ikhawuleza, ukuhanjiswa kuthenjisiwe kwaye umgangatho ungowesibini. Sihlala sizingisa ukucela umngeni kwiinjongo zethu kwaye sibuyisele iintliziyo zethu kuluntu.