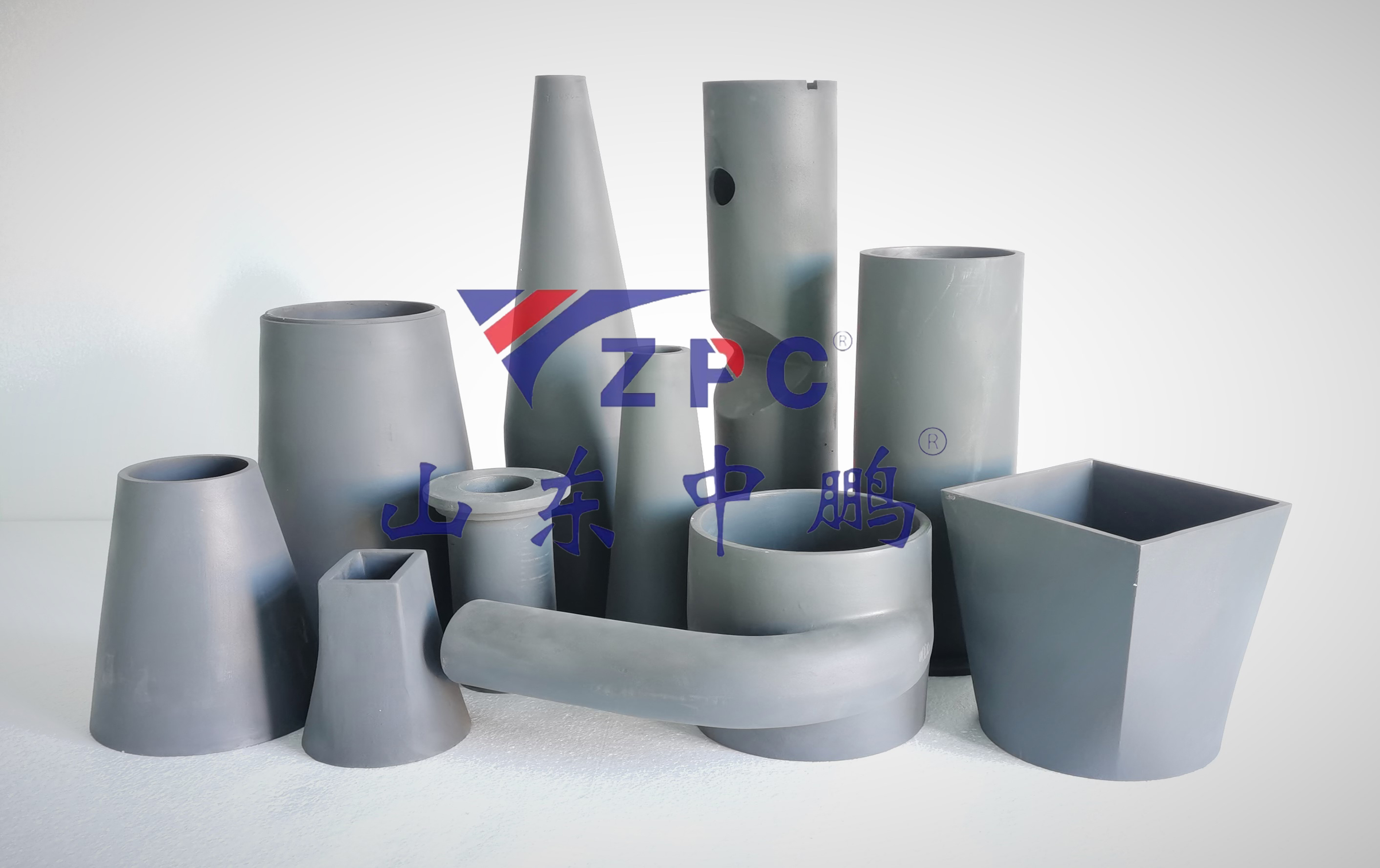

I-silicon carbide iilayini ze-ceramic

I-Silicon carbide inxiba-resistant lining

Iimpawu zoYilo zeSilicon Carbide (SiC) IiLiner eziFanayo zokunxiba:

(1) Uyilo lweNdlela yokuHamba eLungeneyo

Icontour egudileyo, elungelelanisiweyo ukusuka kwi-inlet ukuya kwindawo yokuphuma inciphisa ukuchasana nokuhamba, okwenza ii-SiC liners ziqhelane nezicelo ezahlukeneyo zemizi-mveliso.

(2) IAtomization ekwinqanaba eliphezulu

I-MechanismLiquids yenziwa iathom ibe ngamathontsi acolekileyo ngokungqubana okunetangential kunye nokuncipha ngokuqhubekayo komgangatho we-helical we-SiC liner, eqinisekisa ukusasazwa okufanayo kokutshiza.

(3) I-Compact, i-Clog-Free Structure

Umjelo wokuhamba ngokuthe tye, ongenasiseko ususa izithintelo zangaphakathi, ukwandisa umthamo we-fluid ngaphakathi kwemilinganiselo yemibhobho evaliweyo ngelixa ukhusela ukuvala.

(4) Iindlela ezimbini zokutshiza zokuSebenza ngokuSebenzayo

Ixhasa zombini iipateni zokutshiza zekhowuni eqinileyo kunye nehollow-cone, enikezela ngee-engile zokugquma ngokubanzi kunye nokusebenza okuchasene nokuvala ukusebenza ngokufanelekileyo.

Iinzuzo eziphambili xa kuthelekiswa nezinye izinto:

(1) Ukunganyangeki kokuNxitywa

Ukuqina: Iilayini ze-SiC zifezekisa ubulukhuni be-Mohs be-9.5 (vs. 8.0 yeeseramikhi ze-alumina, i-6.0 yentsimbi ye-chromium ephezulu), ebenza bakwazi ukujamelana nokuguga okugqithisileyo kwi-slurries yemigodi, uthuthu lwamalahle, kunye nomgubo wesinyithi.

Ubomi obude: Ubomi benkonzo budlula i-5–10× imathiriyeli yesintu (umzekelo: iirabha okanye iilitha zepolyurethane) kwizinto ezinefuthe eliphezulu njengeebhola zokusila okanye iimpompo eziludaka.

(2) Ukonakala kunye nokungangeni kweMichiza

Ukumelana ne-Acid/Alkali:Ixhathisa kwi-asidi yesulfuric ejiyileyo (98%), i-sodium hydroxide (50%), kunye neetyuwa ezityhidiweyo (umz. i-NaCl-KCl ku-800°C), ngelixa isinyithi sidleka ngokukhawuleza kwaye iipholima ziwohloke.

Ungcoliseko lwe-Zero: Umphezulu ongasebenziyo uqinisekisa ubunyulu kwi-semiconductor okanye kwimveliso yebhetri ye-lithium, ngokungafaniyo neentsimbi zentsimbi ezithanda ukuvuza i-ion.

(3) Uzinzo loBuzulu obugqithisileyo

I-Thermal Resilience: Isebenza ngokuqhubekayo kwi-1,600 ° C (vs. i-alumina ye-1,200 ° C umda) kunye nokwandiswa okuncinci kwe-thermal (CTE: 4.0 × 10⁻⁶ / ℃), ukuthintela ukuqhekeka kwiikontini okanye kwiziko lokunyibilikisa.

Ukunyangwa koMothuko weThermal:Igcina imfezeko yolwakhiwo phantsi kokutshintsha kobushushu obukhawulezayo (umzekelo, ukucinywa ukusuka kwi-1,000°C ukuya kwiqondo lobushushu begumbi), ngokungafaniyo neeseramikhi ezinqabileyo.

(4)Ubuchule boMbane kunye noYilo oluKhala

I-Friction ephantsi: Umphezulu we-SiC opholisiweyo (i-Ra <0.1 μm) inciphisa ukuxhathisa ulwelo nge-30-50% ngokubhekiselele kwiilitha zentsimbi ezirhabaxa, ukusika iindleko zamandla okupompa.

Ugcino Lobunzima: Ubuninzi be-3.1 g/cm³ (vs. 7.8 g/cm³ yentsimbi) yenza lula ukufakela kwaye ixhase izixhobo ezikhaphukhaphu kwi-aerospace okanye iiyunithi zokusetyenzwa kwemfonomfono.

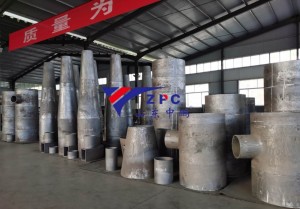

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zikhulu ze-silicon carbide zeceramic ze-ceramic e-China. I-ceramic yobugcisa be-SiC: Ubulukhuni be-Moh yi-9 (ubulukhuni be-Moh entsha yi-13), kunye nokuchasana okugqwesileyo kukhukuliseko kunye nokugqwala, i-abrasion egqwesileyo - ukuxhathisa kunye ne-anti-oxidation. Ubomi benkonzo yemveliso ye-SiC yi-4 ukuya kwamaxesha ama-5 ubude ngaphezu kwe-92% yezinto ze-alumina. I-MOR ye-RBSiC yi-5 kumaxesha e-7 ye-SNBSC, ingasetyenziselwa imilo enzima ngakumbi. Inkqubo yekoteyishini ikhawuleza, ukuhanjiswa kuthenjisiwe kwaye umgangatho ungowesibini. Sihlala sizingisa ukucela umngeni kwiinjongo zethu kwaye sibuyisele iintliziyo zethu kuluntu.