Umenzi (ifektri) yezitena zeSilicon Cabide, iipleyiti, iithayile

I-Silicon Carbide inyamezela uluhlu olubanzi lwee-asidi kunye ne-alkali. Kwaye ngokusebenza okugqwesileyo kokuqina okuphezulu, ubunzima obuphezulu, ukumelana nokunxiba okuphezulu, ukumelana nobushushu obuphezulu, ukuxhathisa umhlwa. Iindidi ezahlukeneyo zeemilo zamalungu akhethekileyo zilungele imigodi, i-petrochemical, i-metallurgical production, i-aerospace kunye nemizi-mveliso yenyukliya, njengendawo yokusingqongileyo ethile. Sinokwenza naziphi na iisayizi ezinikezelweyo ngokwesicelo somthengi.

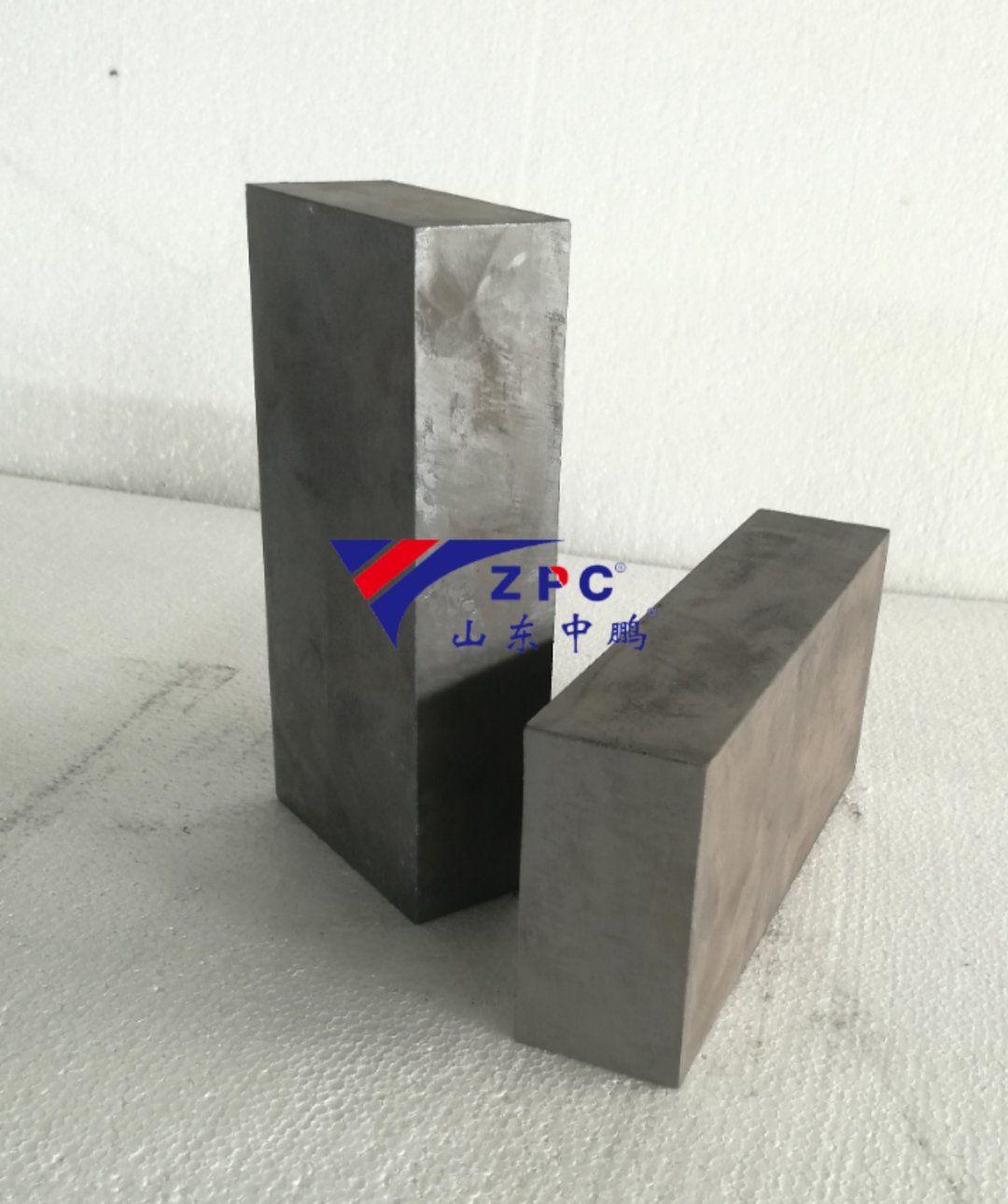

Ukumelana nokunxiba, amandla obushushu obuphezulu kunye nokumelana nomhlwa kwenza i-Reaction Bonded SiC ibe yinto efanelekileyo yezinto ezinxitywayo, ezinje ngeentambo zombhobho, izitena, iithayile, iibhloko, njl.

| Abalinganiswa bomzimba | Iyunithi | Iipropati |

| Umxholo we-SIC | % | 95-88 |

| Mahala Si | % | 5–12 |

| Unizi lolwapho kuyiwa khona | g/cm3 | >3.02 |

| I-Porosity | % | <0.1 |

| Ukuqina | Kg/mm2 | 2400 |

| I-Coefficient yamandla okugoba kwi-20 degrees Celsius | Mpa | 260 |

| I-Coefficient yamandla okugoba kwi-1200 degrees Celsius | Mpa | 280 |

| Modulus of elasticity kwi 20 Degrees Celsius | I-Gpa | 330 |

| Ukuqina kokwaphuka | Mpa*m1/2 | 3.3 |

| I-Coefficient of conductivity ye-thermal kwi-1200 degrees Celsius | W/mk | 45 |

| I-Coefficient yokwandiswa kwe-thermal kwi-1200 degrees Celsius | 10-6mm/mmK | 4.5 |

| I-Coefficient yokushisa ukushisa | <0.9 | |

| Max. Ubushushu bokusebenza | ºC | <1380 |

ISilicon Carbide SiC (SiSiC/RBSiC) Iimpawu:

Ukukrazuka / ukuxhathisa ukonakala

Iimpawu ezigqwesileyo zokothuka kwe-thermal

Ukuxhathisa okugqwesileyo kwe-oxidation

Ulawulo olulungileyo lweemilo ezintsonkothileyo

I-conductivity ephezulu ye-thermal

Ukusebenza okuphuculweyo

Ubomi obude phakathi kokutshintshwa / ukwakha kwakhona

Ukumelana nokubola

Ukumelana okuPhezulu kokunxiba

Amandla kwiqondo lobushushu eliphezulu ukuya kuthi ga kwi-1380°C

Ukusetyenziswa kweepleyiti zeSilicon carbide:

Ipleyiti ye-SiC ye-silicon ye-carbide kunye neethayile luhlobo lwepleyiti ekhethekileyo ye-ceramic esetyenziswa ngokubanzi kwimveliso emininzi yemizi-mveliso:

Ishishini leMigodi, iShishini loShishino, iShishini leMichiza, i-Crystallite Glass Industry, i-Magnetic Materials Industry, i-Metallurgy, i-Metallurgy Industry, i-Paper Industry, i-Petroleum Industry, i-kiln, njl.

Iimveliso ezenziwe ngokwezifiso ze-silicon carbide, imilo ekhoyo: iipleyiti, izitena, iithayile, ipleyiti yeradian, isikrufu, ipleyiti ecacileyo, umbhobho othe ngqo, imibhobho yeti, iringi, ingqiniba, isitshingitshane sekhowuni njalo njalo.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zikhulu ze-silicon carbide zeceramic ze-ceramic e-China. I-ceramic yobugcisa be-SiC: Ubulukhuni be-Moh yi-9 (ubulukhuni be-Moh entsha yi-13), kunye nokuchasana okugqwesileyo kukhukuliseko kunye nokugqwala, i-abrasion egqwesileyo - ukuxhathisa kunye ne-anti-oxidation. Ubomi benkonzo yemveliso ye-SiC yi-4 ukuya kwamaxesha ama-5 ubude ngaphezu kwe-92% yezinto ze-alumina. I-MOR ye-RBSiC yi-5 kumaxesha e-7 ye-SNBSC, ingasetyenziselwa imilo enzima ngakumbi. Inkqubo yekoteyishini ikhawuleza, ukuhanjiswa kuthenjisiwe kwaye umgangatho ungowesibini. Sihlala sizingisa ukucela umngeni kwiinjongo zethu kwaye sibuyisele iintliziyo zethu kuluntu.