Imiqadi ye-silicon ye-carbide

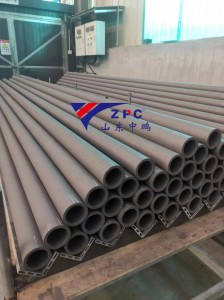

I-Reaction-sintered silicon carbide (R-SiC) iirola zeceramicziye zavela njengamacandelo abalulekileyo kwiinkqubo zanamhlanje zokusetyenzwa kwe-thermal, ngokukodwa ukugqwesa kwi-lithium yokuvelisa ibhetri, ukuveliswa kwe-ceramics ephuculweyo, kunye nokuchaneka kwezinto eziphathekayo zemagneti. Ezi rollers ezikhethekileyo zichaza kwakhona imigangatho yokusebenza kwiziko eliphezulu lobushushu obuphezulu ngokujongana nemingeni ephambili ekuzinzeni kwe-thermal kunye nokuqina komatshini.

UkuSebenza kweThermal okungahambelaniyo

Yenzelwe ukuba isebenze ngokuqhubekayo kwi-1450-1600 ° C - iphezulu kakhulu kuneeroli ze-alumina zendabuko - iirola ze-R-SiC zigcina ukuchaneka kwe-dimensional naphantsi kwebhayisikile eshushu kakhulu. I-microstructure yabo eyahlukileyo yenza ukuba:

• Ukuhanjiswa kobushushu obukhawulezayo (±5°C kubude berola)

• Ukumelana ne-100+ ye-thermal shock cycles (1400°C ↔ ubushushu begumbi)

• I-Zero deformation kumaqondo obushushu azinzileyo

Izicelo Ezibalulekileyo zichazwe ngokutsha

1. Ukuveliswa kwebhetri yeLithium

- Ulungelelwaniso oluchanekileyo lwe-electrode sintering material

- Ukuphathwa simahla kwe-NMC/LFP cathodes

- Ukusebenza okuzinzileyo ekunciphiseni i-atmospheres

2. Advanced Ceramics Processing

-Inkxaso ye-Warp-free kwiithayile zefomati enkulu (ukuya kuthi ga kwi-1.5×3m)

- Ukulawulwa kwesantya esingaguqukiyo kwimigca ye-sanitaryware glazing

- Ukugqitywa komphezulu ongaphawuliyo (Ra <0.8μm)

3. Ukwenziwa kweMathiriyeli yeMagnetic

-Ujikelezo olungashukumiyo lwe-oriented ferrite sintering

-Ukungasebenzi kweekhemikhali kwiindawo ezine-hydrogen etyebileyo

Izinto eziluncedo ngokuSebenza

Umthamo womthwalo: Ixhasa i-3-5 × ubunzima obukhulu ngobude beyunithi nganye vs.

Ukuchasana nokuguqulwa: Igcina <0.05mm / m ethe tye emva kweeyure zokusebenza ze-10,000

UkuSebenza kwamandla: i-18-22% iyancipha ukusetyenziswa kwamandla eziko ngokusasazwa kobushushu

Ukuhambelana kwe-Cross-Industry: Iyakwazi ukulungelelaniswa kwii-shuttle kilns, iindawo zokuhlala ezinamalayile amaninzi, kunye nezitofu ezixutyiweyo zetonela.

Uzinzo loQoqosho

Ngelixa ifuna i-30-40% yotyalo-mali lokuqala oluphezulu kunee-roller eziqhelekileyo, izisombululo ze-R-SiC zibonisa:

- I-70% yamathuba eenkonzo ezinde (iminyaka emi-5-7 vs. 2-3 iminyaka)

- I-90% yokuphinda isetyenziswe ngokusetyenziswa kweenkqubo zokubuyisela i-thermal

- I-60% yeendleko zokulungisa eziphantsi ukusuka kwindawo ekwazi ukumelana nokulimala

Uyilo oluLungele ikamva

Iirola zangoku ze-R-SiC ngoku zibandakanya:

-I-Laser-ekroliweyo yokulandela i-grooves yemigca yemveliso ezenzekelayo

-I-porosity enokwenziwa ngokwezifiso kwiatmosfera ethile

-Iinzwa ezidityanisiweyo ze-thermal kwimisebenzi ye-smart kiln

Olu phuculo lwetekhnoloji lubeka iirola ze-silicon carbide zokusabela njengezinto eziyimfuneko kwiinkqubo zokufudumeza zamashishini ezizayo, ezivumela abavelisi ukuba bafikelele kulawulo olungqongqo lobushushu, ukungaguquguquki okuphezulu kwemveliso, kunye nokuhamba kwemveliso ezinzileyo kumacandelo amaninzi obuchwepheshe obuphezulu.

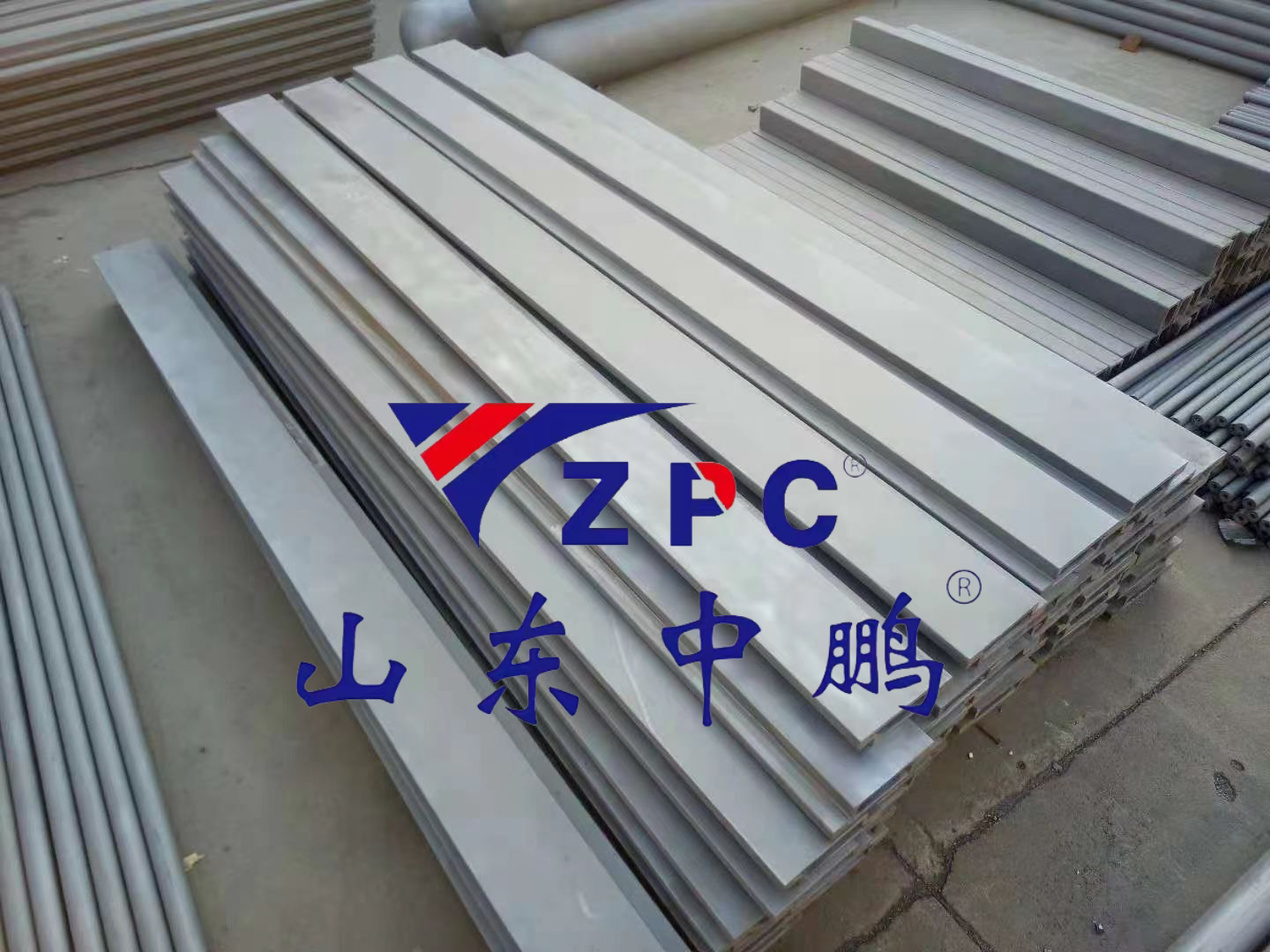

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zikhulu ze-silicon carbide zeceramic ze-ceramic e-China. I-ceramic yobugcisa be-SiC: Ubulukhuni be-Moh yi-9 (ubulukhuni be-Moh entsha yi-13), kunye nokuchasana okugqwesileyo kukhukuliseko kunye nokugqwala, i-abrasion egqwesileyo - ukuxhathisa kunye ne-anti-oxidation. Ubomi benkonzo yemveliso ye-SiC yi-4 ukuya kwamaxesha ama-5 ubude ngaphezu kwe-92% yezinto ze-alumina. I-MOR ye-RBSiC yi-5 kumaxesha e-7 ye-SNBSC, ingasetyenziselwa imilo enzima ngakumbi. Inkqubo yekoteyishini ikhawuleza, ukuhanjiswa kuthenjisiwe kwaye umgangatho ungowesibini. Sihlala sizingisa ukucela umngeni kwiinjongo zethu kwaye sibuyisele iintliziyo zethu kuluntu.