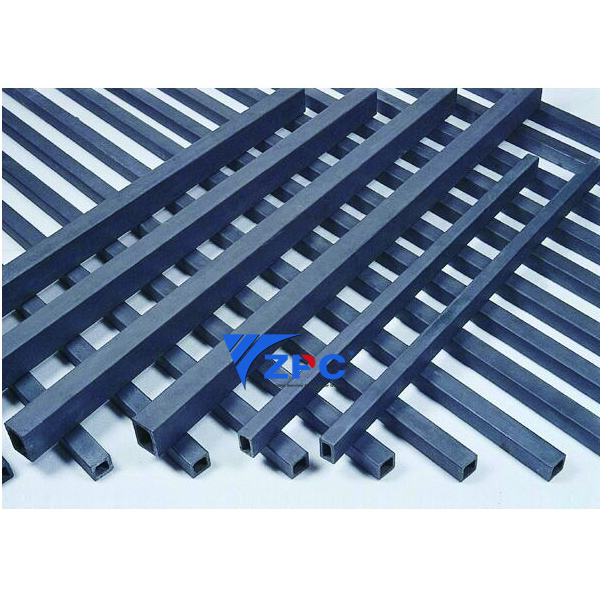

Imiqadi yeSiC

I-Reaction Bonded Silicon Carbide Amandla aPhakamileyo okuTsha okuPhakamileyo Sisic/ Rbsic Rollers kunye neMiqadi

I-Reaction sintering silicon carbide ceramics roller isetyenziselwa ikakhulu kushishino lwebhetri ye-lithium, i-porcelain yemihla ngemihla, i-porcelain ye-sanitary, i-ceramics yokwakha kunye nezixhobo zemagneti, ezifana ne-roller kiln, ubushushu obuphezulu obuvutha nge-kiln efanelekileyo, kunye nobomi benkonzo ende. Inamandla okushisa aphezulu, ukuxhathisa ukothuka kwe-thermal, ukumelana nobushushu obuphezulu, ukuxhathisa okunamandla, ukuxhathisa okulungileyo.

Iiklabhu zisebenza kwimihla ngemihla - iiseramikhi ezisetyenzisiweyo, i-porcelain yococeko, iCeramic yeSakhiwo, imathiriyeli yeMagnetic kunye nendawo yokushisa ephezulu yokudubula ye-roller kiln.

| Inkcazo yeMveliso yeSilicon Carbide: | ||||

| Into | Iyunithi | I-SSIC | RBSIC SISIC | R-SIC |

| Ubunyulu | ( %) | ≥ 99 | ≥90% | ≥ 99 |

| Ubushushu besicelo | ºC | 1700 | 1380 | 1650 |

| Ukuxinana | g/CM2 | ≥3.10-3.15 | ≥3.02 | 2.65-2.75 |

| I-porosity evulekile | % | ≤0.1 | ≤0.1 | |

| Ukuqina | ≥92 HRA | 2400 Kg/mm2 | 1800-2000 Kg / mm2 | |

| Ukugoba amandla | MPa | 400-580 | 250(20ºC) | ≥300 |

| 281(1200ºC) | ||||

| Tensile strength | Mpa | ≥200 | ≥190 | |

| imodyuli ye-elasticity | GPA | 400 | 332(20ºC) | 80-100(20ºC) |

| 300(1200ºC) | 90-110(1200ºC) | |||

| I-Thermal Conductivity | W/mk | 100-120 | 45(1200ºC) | 36 |

| I-Coefficient yokwandiswa kwe-thermal | K1X 106 | 4.2 | 4.5 | 4.6 |

| Ukuqina | Gpa | >25 | 13 | |

| Ukumelana ne-Acid & Ikali | Egqwesileyo | Egqwesileyo | Egqwesileyo | |

| Inkcazo yeMveliso ye-SiC: | ||||

| Into | Iyunithi | OC-1 | OC-2 | MC-3 |

| SiC | (%) | ≥90 | ≥86 | ≥80 |

| I-Porosity ebonakalayo | (%) | ≤10 | ≤13 | ≤16 |

| Ukuxinana | g/CM2 | ≥2.66 | ≥2.63 | ≥2.6 |

| Ubushushu besicelo | ºC | ≥1680 | ≥1620 | ≥1550 |

| I-Coefficient yokwandiswa kwe-thermal | i-aX 10-6/ºC | ≤4.8 | ≤5.0 | ≤5.5 |

| Ukugoba Amandla | 1200ºC | ≥45 | ≥40 | ≥30 |

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zikhulu ze-silicon carbide zeceramic ze-ceramic e-China. I-ceramic yobugcisa be-SiC: Ubulukhuni be-Moh yi-9 (ubulukhuni be-Moh entsha yi-13), kunye nokuchasana okugqwesileyo kukhukuliseko kunye nokugqwala, i-abrasion egqwesileyo - ukuxhathisa kunye ne-anti-oxidation. Ubomi benkonzo yemveliso ye-SiC yi-4 ukuya kwamaxesha ama-5 ubude ngaphezu kwe-92% yezinto ze-alumina. I-MOR ye-RBSiC yi-5 kumaxesha e-7 ye-SNBSC, ingasetyenziselwa imilo enzima ngakumbi. Inkqubo yekoteyishini ikhawuleza, ukuhanjiswa kuthenjisiwe kwaye umgangatho ungowesibini. Sihlala sizingisa ukucela umngeni kwiinjongo zethu kwaye sibuyisele iintliziyo zethu kuluntu.